Introduction

EV performance optimization starts with understanding vehicle behavior under key operating conditions. One of the most critical scenarios for both industry and Formula Student (FS) teams is the Wide Open Throttle (WOT) test - where the throttle is fully engaged, delivering maximum acceleration and power draw with minimal regulation.

Formula Student - Acceleration Event

The Formula Student Acceleration Event challenges teams to cover 75 meters from a standstill—brief but highly competitive. It’s a perfect use case for focused simulations, helping optimize powertrain performance, traction, and launch control.

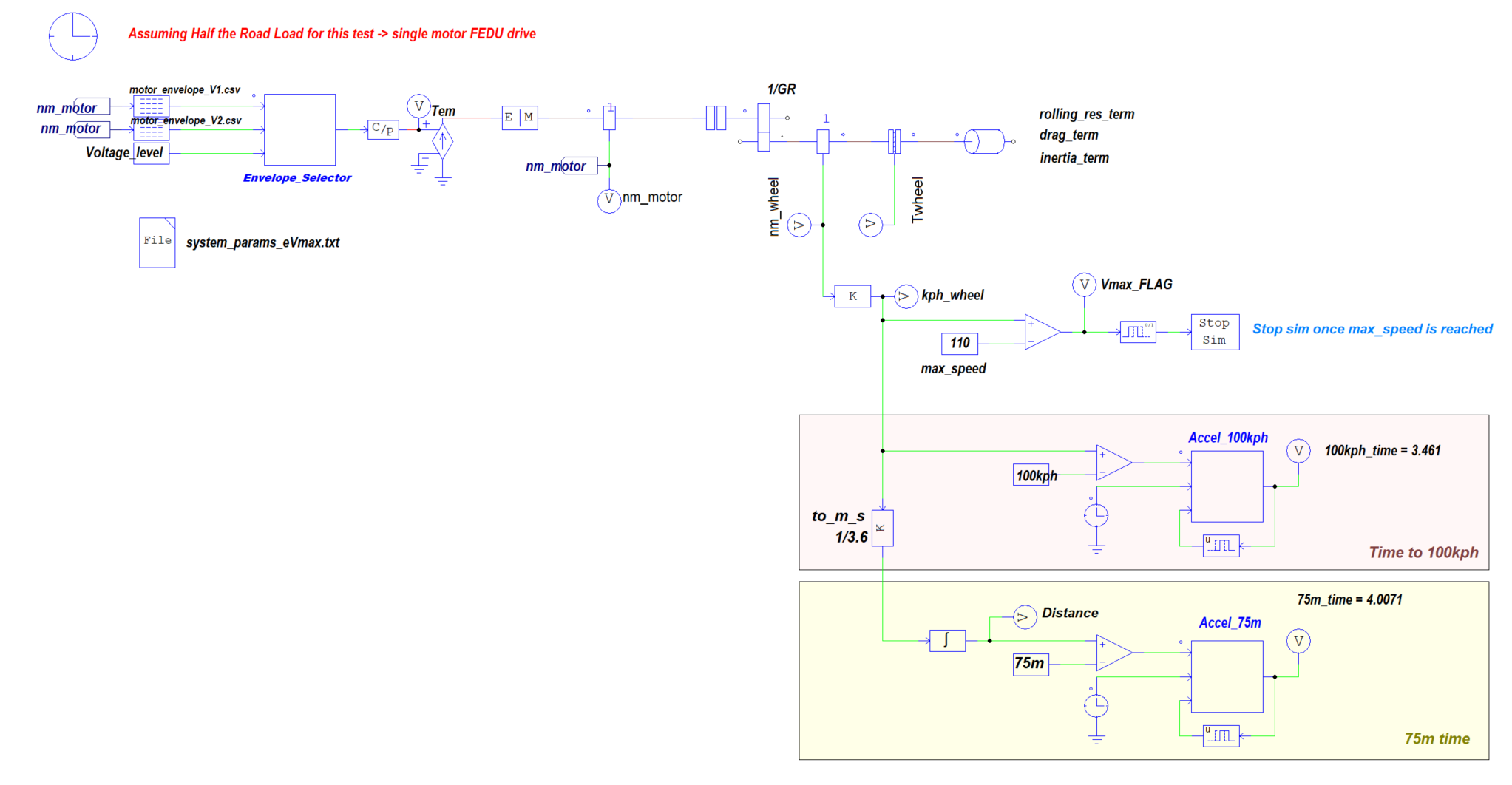

In this article, I present a PSIM based WOT simulation built around a simplified EV powertrain model. This streamlined approach supports fast iterations, design validation, and actionable insight—especially valuable for FS teams operating with limited time and resources.

WOT Simulation

A simple simulation was built to allow users to iterate between two voltage levels (with corresponding motor designs) and four accumulator container options—two for each voltage level. The simulation is very fast (1sec to complete), so far more options could have been implemented and tested.

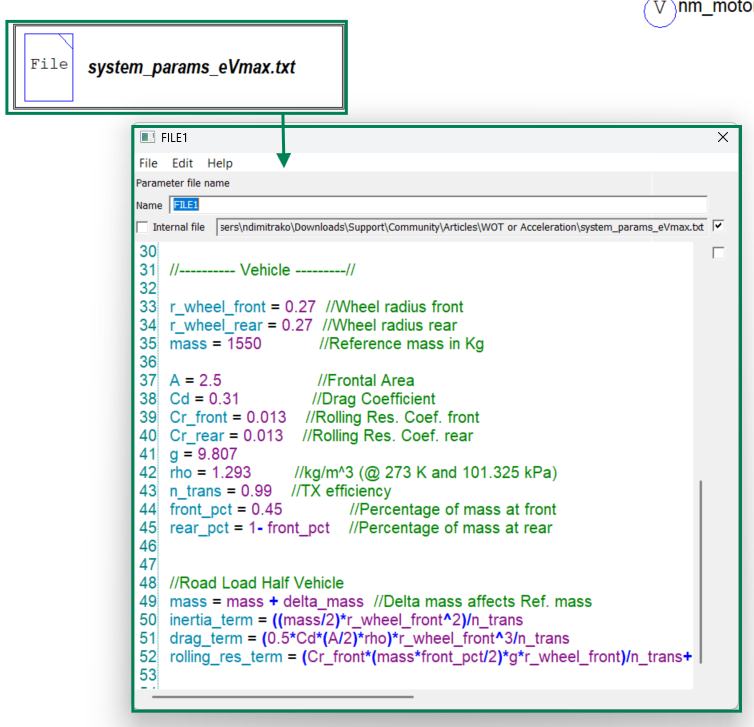

Each container choice affects the total vehicle mass through a delta_mass parameter that is specific to the selected voltage level and accumulator configuration.

The voltage level selection determines which motor torque-speed envelope is applied. In PSIM, when the “E|M” block is used, electrical values are translated into mechanical ones. This means that the controlled current source effectively generates torque at the motor shaft, based on the feedback speed. The road load is connected to the motor shaft via the Gear Ratio (GR). More info about the E|M block can be found here:

Custom Electric Machine Modeling with PSIM blocks

The road load model includes rolling resistance, aerodynamic drag, and the inertia term required for acceleration. Additional vehicle parameters—such as frontal area, drag coefficient, rolling resistance coefficients, and gear ratio—are all defined in a parameter file. More info on the road load can be found here.

This setup enables seamless integration with HyperStudy, allowing users to fully explore the design space. Key performance metrics include time to 100 km/h, 75 m acceleration time (as in the Formula Student Acceleration Event), and accumulator container weight and cost. More info on PSIM + HyperStudy for design space exploration can be found here:

Results

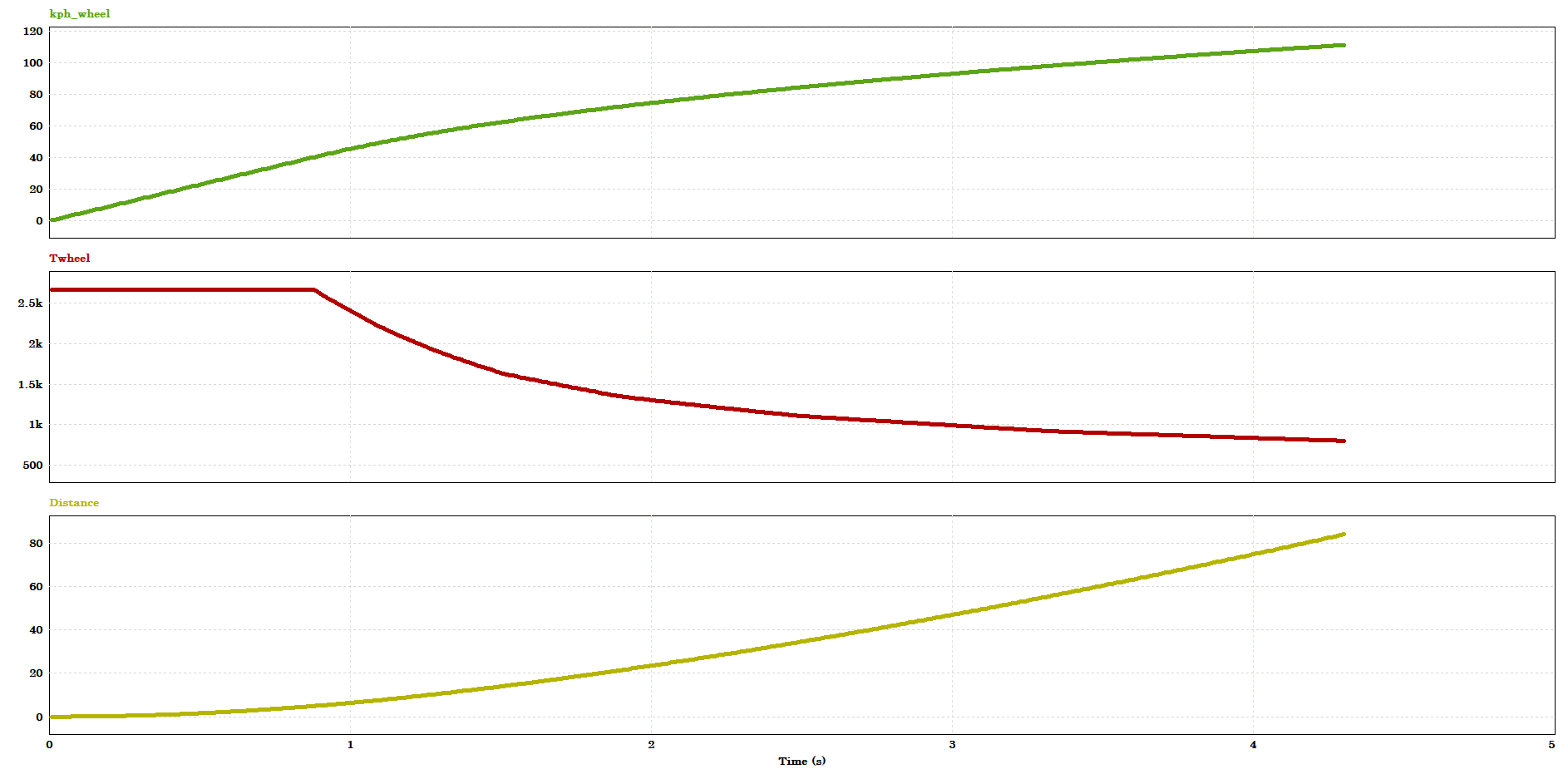

The simulation stops when the vehicle reaches the set maximum speed (110 km/h in this case) or after 8 seconds—whichever comes first.

Additionally, two separate logic blocks are used to detect and record the exact time when the vehicle either reaches 100 km/h or covers a distance of 75 meters.

Below are the simulation results for a sample system, showing wheel speed, torque, and vehicle distance:

Simulation Files

Other Relevant links