1. Introduction

The Cone Penetrometer Test (CPT) is commonly used to characterize mechanical soil properties and often finds application in agricultural and geotechnical engineering. Also, calibration of DEM parameters against CPT results is often considered for modeling and analysis of equipment-soil interactions in applications such as vehicle mobility [1–3].

The cone penetrometer test simulation deck can be downloaded here:

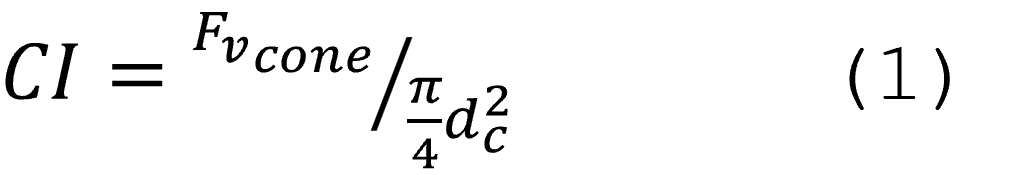

The cone penetrometer test sequence is outlined in Figure 1. The test starts with filling a vessel of sufficiently large volume with particles. This sample is uniaxially compressed under a specified compaction force, followed by unloading. Within EDEM, compression and unloading are achieved through a piston with a 'Force Controller' kinematic, as illustrated in Figure 1(c-d). After compression, with the piston retracted, the test cone penetrates the numerical sample at a constant velocity, as shown in Figure 1(e-f). For the duration of cone travel within the bulk material, the vertical force (Fvcone) on the cone (acting along the 'Z' direction) is recorded. The base of the cone, also the largest dimension of the cone diameter, 'dc' is used for the calculation of the Cone Index.

Figure 1: Test sequence of calibration with cone penetrometer test

The response, derived from the vertical force on the cone, called the 'Penetration Resistance or the Cone Index (CI),' given by equation 1, is often used to calibrate the material interaction parameters against the experimental results.

Several standards for cone penetrometer tests exist in the literature. While some are geared toward soil for agricultural applications, others focus on site stratigraphy and soil characterization under various loading conditions [4–6]. The example deck provided here follows the ASAE S313.3 standards for the test, which has applications primarily (not limited to) in agriculture soil testing [More details in Ref. 7]. A typical evolution of penetration resistance plotted against height from the free surface is shown in Figure 2. The following observations can be made from the plot.

The following observations can be made from the plot.

- The penetration resistance (for the presented example case) increases until a depth of 0.12m, beyond which it fluctuates about a mean value, representing a steady state. These fluctuations can be attributed to the intermittent contact between the cone and the packed particles as the cone traverses down.

- Figure 2 shows an example of averaging where, after every 0.05m of cone travel, the data points are averaged and plotted against the penetration depth. This helps to filter some of the observed fluctuations in CI.

Figure 2: A typical response of a cone penetration test

The cone penetrometer test is performed in the quasi-static flow regime (shear rate-independent), and the linear translation of the cone into the packed solid bed can be increased in the interest of computational efficiency, provided the inertial number (given by equation 2) remains less than 1e-3 [6,8].

A reasonable estimation of strain rate can be made from equation (3) based on the works of Janda et al. [6] and Lu et al. [9]

2. Modeling Methodology

Two simulation decks for calibration against CPT results are provided and can be accessed here. The cone geometries for both decks conform to ASABE standards[10] for characterizing penetration resistance for hard and soft soils. The selection of the deck for the calibration process should be made based on a qualitative assessment of Hard/Soft soils. For soft soils, Cone Penetrometer A with a larger base diameter is recommended, whereas, for hard soils, Cone Penetrometer B with a smaller base diameter should be used [10]. The user can also import custom cone geometry using EDEM's geometry import functionality.

The consolidation stress before the cone penetration significantly influences the test results [6]. The higher the consolidation stress, the larger the penetration resistance. EEPA contact force model is used to capture the stress history-dependent behavior of the soils [11, 12]. Using EDEM's force controller functionality, the piston can be programmed to apply a set compressive stress (10kPa in this case), as illustrated in Figure 3. At the peak of compression, the numerical sample is allowed to stabilize (by holding the compressive force for a few steps), followed by unloading. After unloading, the cone is pushed into the numerical sample at a steady velocity of 0.03m/s using EDEM's linear translation kinematics.

The example decks, along with the EDEMPy Python script provided here, can be used as a guide/ template to further modify the sample size (cylinder volume), compaction force, cone geometry, and depth of cone penetration. For case-specific applications, the simulations may be required longer to achieve a steady state for cone penetration resistance.

Figure 3: EDEM workflow for assigning motion kinematics to (a) piston and (b) cone for modeling CPT

3. Post-processing using EDEMpy

The CPT results, as shown in Figure 4, can be automatically exported from the completed EDEM simulations using the 'Cone_penetrometer_analyst.py' script provided with the example CPT model here. This Python script utilizes the EDEMpy library for post-processing EDEM simulation data to compute and export the results in graphs like the ones shown in Figure 2 and CSV files like the ones shown in Figure 4(a). This Python script file is accompanied by its corresponding settings file, 'CPT_Analyst.txt,' which identifies the type of cone geometry used for simulation.

The CI values are reported in a CSV file in the following order.

- The average mobility cone index (marked A in Figure 4) is the penetration resistance of the cone for the first 150mm of penetration depth. This value typically finds applications in traction models for vehicle mobility [13].

- The average cone index (marked B in Figure 4) is an arithmetic mean of the cone's penetration resistance for every 50mm of travel within the packed numerical sample.

- The cone index corresponding to the penetration depth per save interval (marked C in Figure 4). The penetration depth is measured relative to the base of the cone and from the predefined datum, as illustrated in Figure 5.

Figure 4: Results reported in a CSV file from EDEMpy script containing (a) average mobility cone index, (b) average cone index, and (c) cone index

Figure 5: Schematic representation of the datum/ reference line used for subsequent depth measurements for CPT

Multiple simulation decks (run till completion) can be post-processed by arranging files into one of two configurations, as shown in Figure 6. In configuration two (Figure 6(b)), each simulation deck can be post-processed with its custom setting file, whereas, in configuration one (Figure 6(a)), a single setting file is read for post-processing of all the EDEM decks. The following sequence outlines the workflow for post-processing.

- Arrange the files as shown in Figure 6.

- Open an existing/blank EDEM simulation file and go to EDEM Analyst-->Run EDEMpy Script.

- Select ‘Cone_penetrometer_analyst.py’-->Run Script.

- Reports and graphs will be generated in the master folder

Figure 6. Configuration of folders for post-processing using the EDEMpy script (a) single setting applicable to all EDEM decks, and (b) provision for custom settings for each simulation deck

Further Readings

This article outlined one of several calibration techniques used in DEM simulations. You can access details on other calibration techniques and useful EDEM resources below

Accelerate your EDEM Learning

Modeling a uniaxial compression test in EDEM

Modeling a shear cell test with EDEM

Material model calibration using Static Angle of Repose test with EDEM

Modeling FT4 Rheometer test with EDEM

References to the current article can be downloaded here.