Altair FluxMotor 2025

Altair FluxMotor is encapsulating modeling know-how of electric machines and delivers ready-to-use models and virtual tests, to help you speed up the design process. It is based on templates of a list of motor types that is constantly growing. With the new version, DC machines are added, which is saving a lot of modeling time spent in defining Finite Element models of such machines. Obviously, you cannot limit yourself to existing templates, and customization of parts is essential. A new way of creating your own parameterized parts is introduced. It is based on the SimLab sketcher, which provides a very intuitive and efficient environment for such tasks.

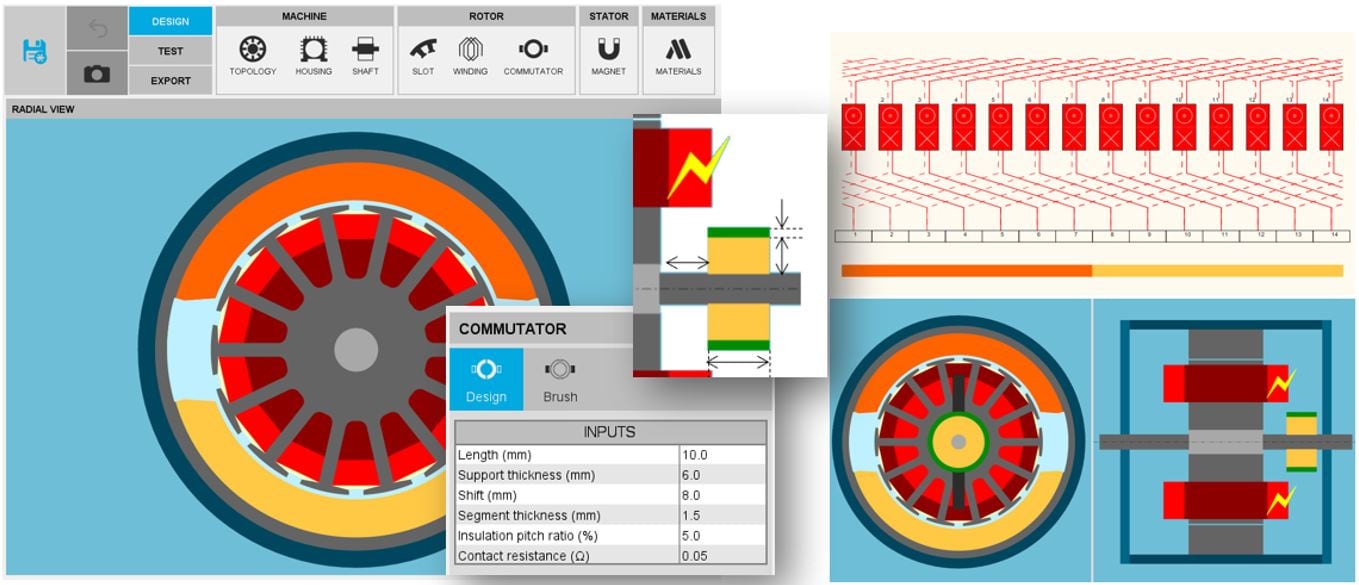

SPEEDING UP THE MODELING OF DC MACHINES

PMDC machines are cheap to manufacture and can be found in many applications. It is also known by Finite Element software users, to be cumbersome to model, mainly because of the brushes and the commutator. What about generating a PMDC machine model in just a few clicks? FluxMotor is now able to do that and automatically creates the geometry, the mesh and the physics definition. A fully automated working point test is also there for testing the machine performance.

Modeling of PMDC machines in Altair FluxMotor 2025

ADVANCED TESTS FOR WOUND FIELD SYNCHRONOUS MACHINES

Wound field machines are widely used for power generation. A new test has been added to analyze the machine at no-load. It is a first step to evaluate the relevance of the machine design regarding not only parameters such as topology, winding architecture, composition of coils and choice of materials, but also the impact of the applied field current value in the magnetic saturation of the machine.

The typical question you have when designing a wound field machine is whether the operating point you try to get is reachable. This can be easily answered by using the working point test, which will help you identify the appropriate values for the field current and the control angle needed to achieve this operating point. This advanced test is using optimization based on performance maps depending on Id, Iq and the field current If.

Similarly to what is offered for PMSMs, NVH performance can also be assessed for wound field machines now. It brings fast NVH predictions in the early design stage. The modal analysis of the stator mechanical structure, the radiated sound power and the magnetic forces applied on teeth are computed and displayed.

Automated search in the P-Q plane if a targeted working point can be reached by the wound field machine

EASY CUSTOMIZATION OF PARTS

It is now possible to create parameterized parts that can be used in FluxMotor. A dedicated environment is available through SimLab to sketch parts and parameterize them in a modern and easy-to-use dedicated environment. You can create parts from scratch or re-use already existing ones in the catalog, adjusting details or adding features. You can also import from CAD. This is an important addition as it is a much easier way to apply FluxMotor automated processes to any topology of parts, not limiting yourself to the existing parameterized templates.

Sketch your part, bring it into FluxMotor, change parameters if needed and compute !

AND ALSO

- Three news exports of the thermal scheme from FluxMotor to Flow Simulator

- Working Point Test Enhancements for synchronous machines

- IMSQ Power balance, Fast and Accurate modes improvements

- Tutorials, best practices documents and videos are available on the online user help guide: Link

Get all the details in the Release Notes [Link]

If you want to learn also about Flux and its new features, follow this [Link]

Enjoy the new version !#OnlyForward

Fabrice Marion - Senior Program Manager - FluxMotor®

Vincent Leconte - Senior Director Electrification Solutions