Best Of

Re: Preisach model under FLUX

Hello,

Thanks for reaching out.

Please find the detail information using below links:

Isotropic soft magnetic material: hysteresis Preisach models

Evaluating iron losses à priori in magnetic cores

If you are looking for additional help or support modelling your custom material, I request you to create a support ticket. So we can look closely into your request and help you with modelling.

Please don't share any files here as this is public forum and can be accessed by everyone.

Best Regards,

Charishma.

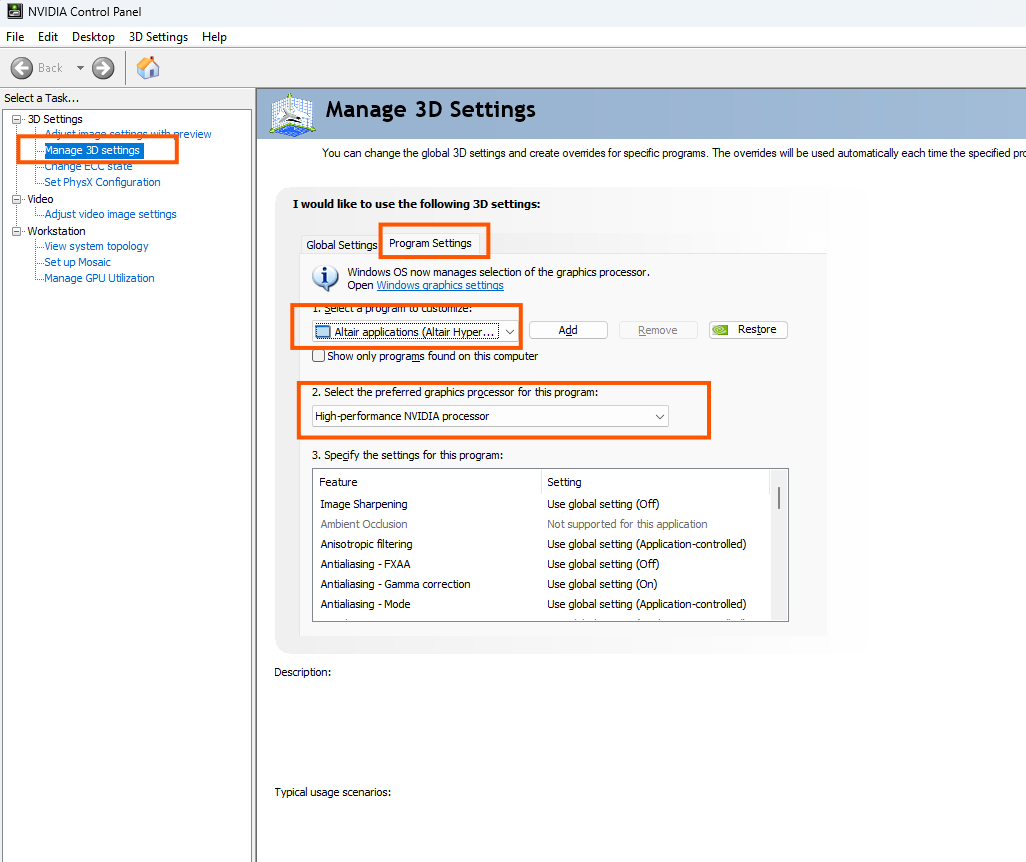

Re: ¿Cómo puedo hacer para que mi tarjeta de video no bloquee hypermesh?

Hola,

Este error parece estar relacionado con la GPU.

- Debe verificar si tiene alguna de las tarjetas dedicadas compatibles:

https://help.altair.com/hwdesktop/altair_help/topics/getting_started/hw_recommendation_certifications_intro_r.htm?zoom_highlight=hardware

- Si el driver de la tarjeta está actualizado

- Además, le recomiendo que consulte esta otra discusión, que muestra cómo definir la GPU dedicada como predeterminada para HyperWorks

Gracias,

Arthur

Re: HyperView2024 - python - macro

Hi, Fábio,

I would recommend to check this other discussion:

Also, I´ve attached an example, you can use it to guide yourself. Just a point, I would recommend to update the HyperWorks version to 2026, new API are available.

https://help.altair.com/hwdesktop/hwd/topics/reference/extensions/hwpy_studio_ribbons_xml_r.htm

Regards,

Arthur

Re: My Rapid Miner account is blocked

Please use the free student edition in Altair one which includes Altair AI studio (previously known as Rapidminer studio) as per the following guide -

Please ensure to NOT enter your Altair One Credentials in the RapidMiner Login window of AI Studio, and click on switch to Altair Units license as guided here - https://www.youtube.com/watch?v=2uJg6heRZBs. Your account is active in Altair one. To use Altair AI Studio (previously called RapidMiner Studio), you need to make sure you are switching to Altair Units Licensing while accessing AI studio.

- Follow the Troubleshooting instructions if using Windows - https://community.altair.com/discussion/33114/steps-to-activate-ai-studio-with-the-altair-student-edition-license-key-from-altair-one-com-in-windows-and-other-related-ai-studio-troubleshooting.

- Follow the Troubleshooting instructions if using MAC OS - https://community.altair.com/discussion/33209/steps-to-activate-ai-studio-with-the-altair-student-edition-license-key-from-altair-one-com-in-mac-os-apple-and-other-related-ai-studio-troubleshooting

Thanks!

Ankita_v

Ankita_v

Re: Turbo Prep and Auto Model Not Activating After Student Edition Installation

I appreciate your help. Your suggestions and the point below solved the problem.

Re: Selection HEXA elements by Face using tcl

Hi, Vladimir_Gantovnik,

Currently, we don´t support this selection method via API (python and tcl) for 3D elements, just for 2D

import hm

import hm.entities as ent

model = hm.Model()

source_col = hm.CollectionByInteractiveSelection(model, ent.Element)

face_col = hm.CollectionByFace(model, source_col)

print(len(face_col))

Could not be the best approach, but as a workaround, you can request this selection as a *createmarkpanel

https://help.altair.com/hwdesktop/hwd/topics/reference/hm/_createmarkpanel2.htm?zoom_highlight=*createmarkpanel

Regards,

Arthur

Re: batch rename connections

Hi Srini,

Currently, SimSolid does not provide a built-in feature to batch rename connections similar to how materials can be assigned in batch mode. Connection names must typically be updated manually when created. However, you can achieve a similar result using the JavaScript API, where a script can loop through all connections and automatically rename them based on the parent assembly, part, or any naming convention you choose. This approach mimics batch material assignment by applying consistent updates to multiple items at once, saving time in large assemblies.

Regards,

Sourav

Re: Turbo Prep and Auto Model Not Activating After Student Edition Installation

Hi @userbester

Please switch from RapidMiner Free Edition to Altair Student License in AI Studio as per -

Please see this guide with FAQs for additional assistance in understanding Altair's Student Edition with Altair Licensing vs the Educational Version with RapidMiner Licensing -

Additionally, you may see the following video playlist that walks you through how to use the free Altair student license from Altair One to activate AI Studio -

Thanks

Ankita_v

Ankita_v

Re: Unit System Configuration & Interpretation in SimSolid

Hi Sourav

Thank you so much for your Inputs. This helps . May be in the next releases . Difficult for user to look into different locations to ensure the units are consistent. These features can be captured next revision i hope

thank you

Regards

srini

Re: Unit System Configuration & Interpretation in SimSolid

Hi Srini,

In SimSolid, unit system preferences are not fully configurable via configuration files like solution settings, so switching units often requires manual adjustments. For example, in the Virtual Connector Bushing settings, stiffness may display in N-m even if you’re working in N-mm; this is not a GUI glitch, as SimSolid internally handles the correct conversion, but the display units are fixed. Similarly, gravity loads are interpreted according to the selected unit system for instance, 1G is internally converted to 9806.65 mm/sec² when using mm/sec². To avoid inconsistencies, it’s best to use a consistent unit system across the model, carefully check dialog units, and adjust input values where display units differ. Currently, there is no global configuration or environment variable to define unit preferences.

Regards,

Sourav