I am trying to run a material non-linear analysis on my sample, but I keep getting *** ERROR # 4966 *** Minimum time increment reached, analysis aborted.

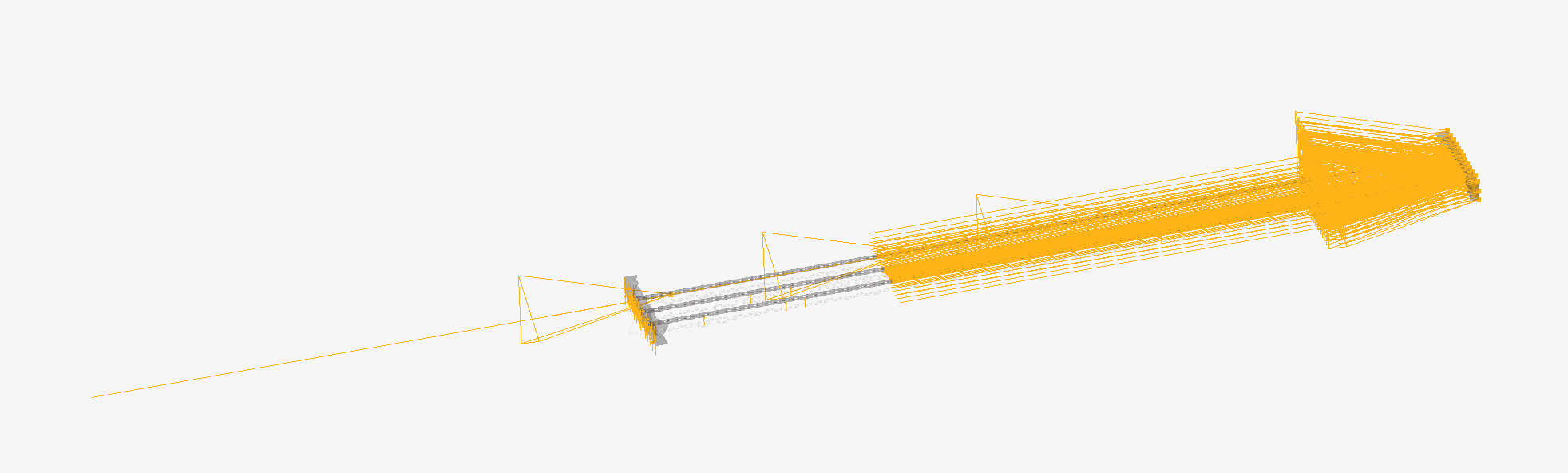

Hello! For context, I am making a simulation of a 3-D tensile sample. The sample is compromised of a PETG base with carbon fiber filaments implemented inside the base. I am trying to run a material non-linear analysis and I keep recieving *** ERROR # 4966 *** Minimum time increment reached, analysis aborted.

I have an idea that it might have to do with the auto contact setting I implemented or how the sets I created for the pulling load and boundary condition were made but I could be wrong. Please let me know if I need to clarify any information.

Attached is my hm file.

Find more posts tagged with

Hi

I did add a RBE2 to the left side holding the specimen and then added a rbe3 for loading on the right side!

Updated the BC and force set to just include 1 single node each

Model runs fine now.

/johan

Hi

I did add a RBE2 to the left side holding the specimen and then added a rbe3 for loading on the right side!

Updated the BC and force set to just include 1 single node each

Model runs fine now.

/johan

Hello!

Thank you so much! I'm very new to Hyperworks so I am trying my best to learn as much as I can. The reason why I wanted to make a set is because it was my understanding that doing so for a force for example would mean that the end would have a uniform pulling load. But it turns out I had a multiple amount of loads.

I've never had to use the rigid body command but looking into it, it just seems like a better way to run the simulation. I should have looked into this before.

Again, thank you for your help!

Hi

I did add a RBE2 to the left side holding the specimen and then added a rbe3 for loading on the right side!

Updated the BC and force set to just include 1 single node each

Model runs fine now.

/johan

Hi

regarding the loads, is supposed to have FORCES on all nodes in you force set?

A good start would be to apply displacement control on the "right side" instead of forces.

Regarding time step min you can control this with the nladapt card

$HMNAME LOADSTEPINPUT 3"nladapt"

NLADAPT 3DTMAX 0.1DTMIN 0.0001

Kind regards

/Johan