Overview

PREFACE

Physical vehicle testing is expensive and resource intensive. Vehicle modeling and simulation provide an efficient addition to the design process which can be implemented prior to physical testing to understand a vehicle’s dynamics. Multibody dynamics software, like Altair MotionSolve, allows users to set up and analyze a wide range of dynamic systems, including vehicles. Additionally, MotionSolve lets users simulate a large selection of vehicle events to analyze vehicle performance parameters. Results can be used to refine vehicle design and improve occupant comfort.

INTRODUCTION

Two-wheelers and three-wheelers, including motorcycles, bicycles, rickshaws, and scooters, are used for travel, transportation, or fun. Like cars, two and three-wheelers must meet engineering requirements and ensure passengers are comfortable. Altair MotionSolve’s extensive vehicle simulation tools can be used to analyze two-wheelers and three-wheelers’ vehicle dynamics, including vehicle stability and driver/passenger safety. Components can be analyzed for durability to estimate component damage or fatigue life. Finally, simulation in MotionSolve allows for rider comfort predictions. This allows active systems to be tuned using a digital twin before being tested on the road.

TWO/THREE-WHEEL VEHICLE SIMULATION IN HYPERWORKS

Altair’s HyperWorks is an end-to-end CAE software platform for design and simulation. Pre-processing, solving, and post-processing are integrated into one platform. Vehicle simulation can be performed quickly, easily, and accurately on one platform.

The process begins with assembly in the MotionView client. Users can choose from example vehicles or build a new motorcycle or scooter by following along an assembly wizard. Assembly options for 2-wheelers include:

Front Suspension

- Classic Telescopic Fork

- Inverted Telescopic Fork

Rear Suspension

- Mono-shock Trailing Arm

- Twin-shock Trailing Arm

Powertrain

- Linear Torque Map

- IC Engine

- Electric Powertrain

Frame

Brakes

Tires

Pre-Built Vehicles Ready to be Populated with Design Data

The pre-built suspension and steering systems can then be populated with design data. After building the vehicle model, users can select from a wide selection of vehicle events from kinematics & compliance testing to double lane change maneuvers and rough road courses.

Once the model is built and an analysis event has been selected, the model is exported to MotionSolve where it computes a solution. Once the analysis has been completed, users can view animation results in the MotionView client. Alternatively, many more options for animation results are available in the HyperView client. For example, users can create contour plots of stresses on flexible components or vector plots of forces. Lastly, key performance indicators can be extracted and plotted in the HyperGraph client.

Pre-Requisite

SOFTWARE REQUIREMENTS

Altair MotionView (2024 or newer)

Altair MotionSolve (2024 or newer)

EXAMPLE TWO/THREE-WHEELER MODELS

Two_Three_Wheeler_Examples.zip

Usage/Installation Instructions

SIMULATION STEPS

- Pick a model to run and open the .mdl in MotionView.

- Run the analysis and review the results.

Post-Requisite

EXAMPLE TWO & THREE-WHEELER RESULTS

MotionSolve allows users to analyze vehicles on rough or smooth roads. An event library includes real-world vehicle events like lane changes which can be used to evaluate component durability and vehicle handling. MotionSolve also allows the creation of custom road events for further analysis.

Motorcycle Traveling on a Rough Road

Motorcycle Double Lane Change Maneuver

Vehicle shaker testing is commonly performed to validate vehicle performance, identify failure points, and understand rider comfort. A simulated shaker test provides similar value. Prediction of failure points before manufacturing can be used to improve the design and cut costs in physical vehicle testing.

Motorcycle Shaker Testing

Motorcycle Frame Stresses

One method of analysis made possible in simulation is the drum road. A rotating drum with a rough surface is made below each tire. The vehicle, in this case a rickshaw, drives causing the drums to spin. The vehicle experiences cyclical loading due to the rough road allowing for fatigue analysis directly from loads created by a multibody dynamic simulation.

Auto Rickshaw Drum Test

Three-Wheeler Double Lane Change Maneuver

Three-Wheeler J-Turn Maneuver

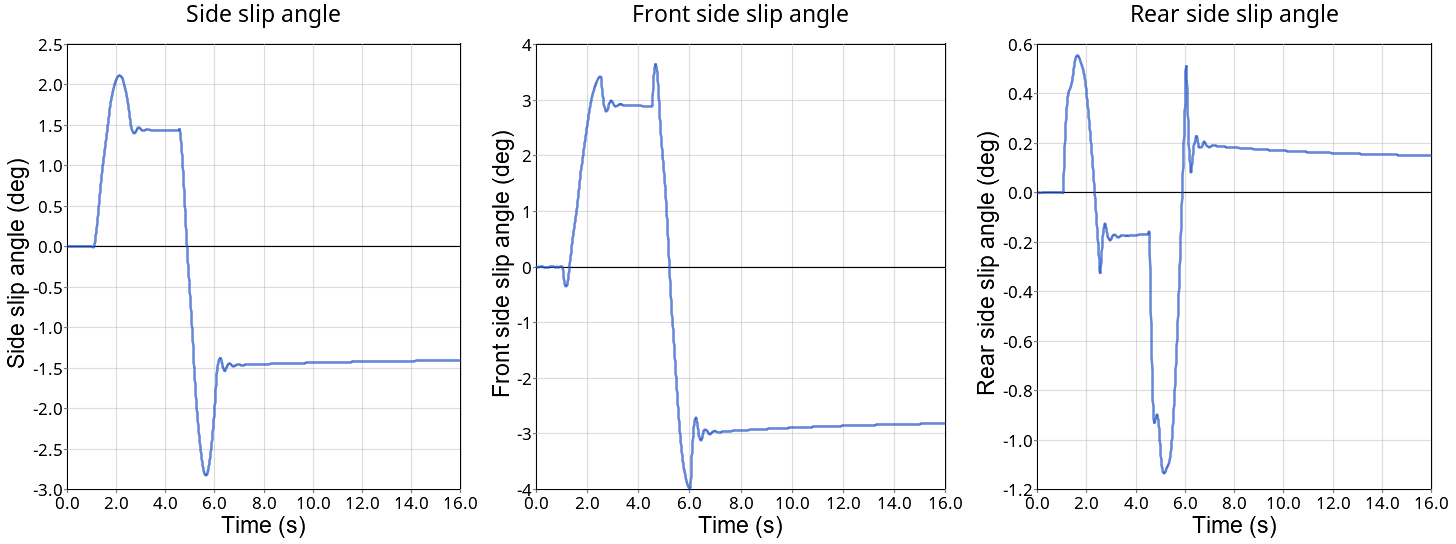

The HyperGraph client allows users to plot key performance indicators. For example, vehicle side slip angles can be plotted over time.

Three-Wheeler Slip Angles during the J-Turn Maneuver

CONCLUSION

Simulation is a powerful tool capable of emulating real-world behavior of vehicles on a variety of terrains under a wide range of vehicle events. HyperWorks is one such simulation platform allowing pre-processing, solving, and post-processing quickly, easily, and accurately. In the MotionSolve client, vehicles can be built and populated with design data to test vehicle performance, durability, and evaluate rider comfort. In this example, we demonstrated the results from several simple vehicle models. More complex models can be built, evaluated, and improved using the same workflow.

AUTHORS

John Dagg, Systems Engineering Intern

Christopher Fadanelli, Solution Engineer - Systems Integration