Overview

INTRODUCTION

Designing an airplane for safe, controlled landings is one of the most challenging tasks aerospace engineers face. The landing gear must absorb the impact of landing and limit shock to the airframe. The airplane must remain stable and in pilot control during a landing under various weather conditions. There could be crosswinds, rain, ice on the runway, and other adverse conditions the plane must be able to handle. In addition to the above challenges, select planes are designed to land on unpaved runways. Gravel or dirt runways affect the plane’s handling and can damage the fuselage, wings, or engine if flung upwards by the front landing gear. Planes designed to land on unpaved runways often come equipped with a gravel kit on the front landing gear which blocks debris from damaging the plane and entering the engines.

Real-world testing of plane designs can be extremely costly, time-consuming, and risky. Simulation allows engineers to analyze and validate individual components on a plane or the full system. Combining multibody dynamics (MBD) software with a hydraulic model and bulk material model allows for a comprehensive analysis of an airplane landing. In this example, we use Altair MotionSolve to build an MBD model of a business jet decelerating on an unpaved runway. A hydraulics model built using Twin Activate, an intuitive physics modeling software, accurately models the landing gears. Cosimulation with EDEM, a discrete element method solver, models the plane’s interaction with a gravel runway. After building the model, we run a baseline analysis to review the gravel spray. Then we add a gravel kit, rerun the analysis, and compare the results.

Understanding the Model Definition in MotionSolve

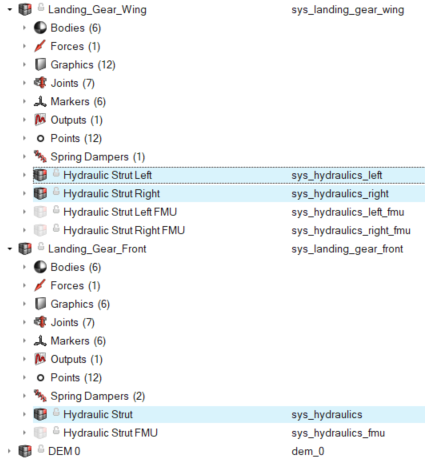

First, the MBD model is built from CAD data in MotionSolve.

Understanding the Model Definition in Twin Activate

The Twin Activate model handles the physics of the oleo struts using a Modelica hydraulics model. The strut is represented as a plunger cylinder. Strut force is dependent on piston stroke and velocity which is realized using a look up table. Each timestep, Twin Activate receives piston position and velocity from MotionSolve and uses the hydraulic model to calculate the strut force which gets sent back to MotionSolve. Twin Activate performs this process for all three landing gears.

Understanding the Model Definition in EDEM

The EDEM model includes 1 million particles on the runway with a 4-5 mm particle diameter. Particle properties come from the GEMM library, a source of validated bulk material properties. Particle-particle and particle-airplane interactions are modeled using a Hertz-Mindlin contact model, which accurately and efficiently compute forces. The particles have contacts with the wheels, landing gear components, and plane body to accurately represent the soil-plane interaction.

Pre-Requisite

SOFTWARE REQUIREMENTS

MotionView (2024 or newer)

MotionSolve (2024 or newer)

Twin Activate (2024 or newer)

EDEM (2024 or newer)

MODEL FILES

Aircraft_Landing.zip

Usage/Installation Instructions

MODEL SETUP & SIMULATION STEPS

- Start a new MotionView session.

- Open Aircraft_Landing.mdl or Aircraft_Landing_no_kit.mdl in MotionView.

- Ensure the FMUs are disabled, and the highlighted systems are enabled.

- Export the solver deck for co-simulation with Twin Activate. File > Export > Solver Deck and select the Results folder.

- Start a new EDEM session.

- Open Aircraft_Landing_Bulk.dem or Aircraft_Landing_Bulk_no_kit.dem in EDEM.

- Start the coupling server in EDEM.

- Start a new Twin Activate session.

- Open LandingGear_Activate.scm in Twin Activate.

- Open the aircraft superblock and double click the MotionSolve block.

- Change the input file to the xml file created by exporting MotionSolve’s solver deck.

- Save the MRF output file to the results folder.

- Hit run to begin the co-simulation.

- Once the simulation is complete, find the dem file in the EDEM folder and open the file in HyperView to review the results.

Post-Requisite

RESULTS

The gravel kit dramatically decreases the particle spray from the front landing gear. Less gravel and dirt are sprayed up into the fuselage, wings, and engines preventing any damage to critical components. This effect is best observed in the closeup on the front landing gear and the front view of the plane.

Airplane Landing with a Gravel Kit

Airplane Landing without a Gravel Kit

Front Landing Gear Gravel Spray

Front View of Gravel Spray

CONCLUSION

Simulation is a powerful tool which can aid in the design and validation of aerospace systems including airplanes. In this example, we built a model of an airplane landing on an unpaved runway. Co-simulation with digital twin software, Twin Activate, modeled the oleo struts on each landing gear. A dedicated bulk material solver, EDEM, handled the airplane’s interaction with the gravel runway. Results showed the gravel kit significantly reduced the gravel spray from the runway. This will prevent debris from damaging the fuselage, wings, or engine.

AUTHORS

John Dagg, Systems Engineering Intern

Stefanos Stathis, Application Specialist

Christopher Fadanelli, Solution Engineer - Systems Integration

Ananth Kamath Kota, Global Technical Manager - Systems Integration