- RESEARCHER

- Ruihuan Ge

- INSTITUTE

- Monash University, Australia

- DEPARTMENT

- Chemical Engineering

- SUPERVISOR

- Prof. Karen Hapgood

- TIMELINE

- 20/09/2014 - 20/09/2018

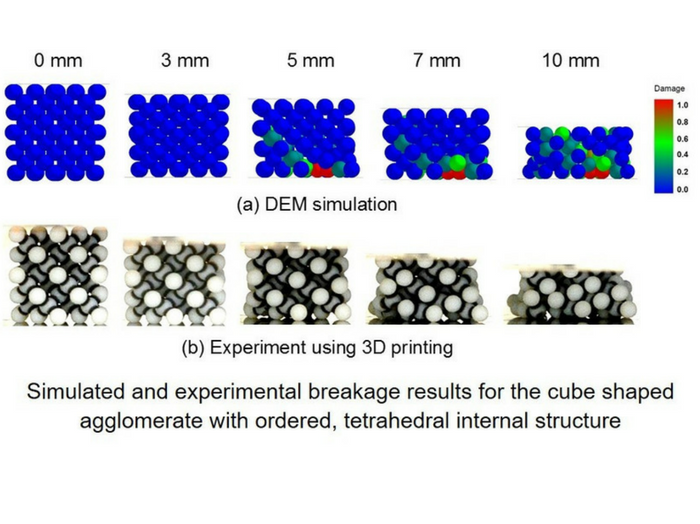

It is essential to offer a universally accepted way to systematically evaluate agglomerate breakage propensity and mechanisms. Discrete Element Method (DEM) simulation is a commonly used tool, but is limited by the lack of identical, controlled agglomerates to test and validate simple models, let alone replicate the complex structure of real industrial agglomerates. Our research presents a systematic approach to produce 3D printed agglomerates with tuneable properties. Agglomerates with different mechanical properties and structures were designed and printed by an Objet 500 Connex 3D printer. This 3D printing method will allow more rigorous testing of agglomerate breakage models. In our research, EDEM will be used to model the single agglomerate breakage behaviors, and compare these results with experimental breakage results of 3D printed agglomerates.

SPONSOR -

International Fine Particle Research Institute, IFPRI

PERSONAL WEBPAGE -

www.researchgate.net/profile/Ruihuan_Ge/publicationsFig. 1. Design agglomerate and 3D printing

Fig. 2. Discrete Element Method simulation and experiment comparison

EDEM offers a helpful, easy and friendly way to perform DEM research.