Hello guys,

I'm working on my master thesis which is the structural optimization of a rear wing for a race car.

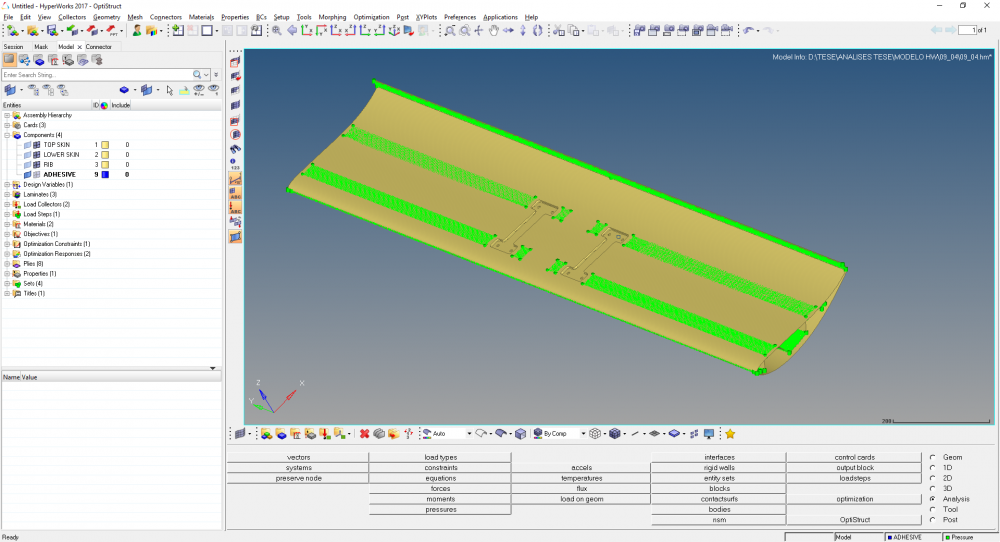

The wing is composed of 2 skins (top and lower) and one structural rib on the middle. All these parts are bonded together.

<?xml version="1.0" encoding="UTF-8"?>

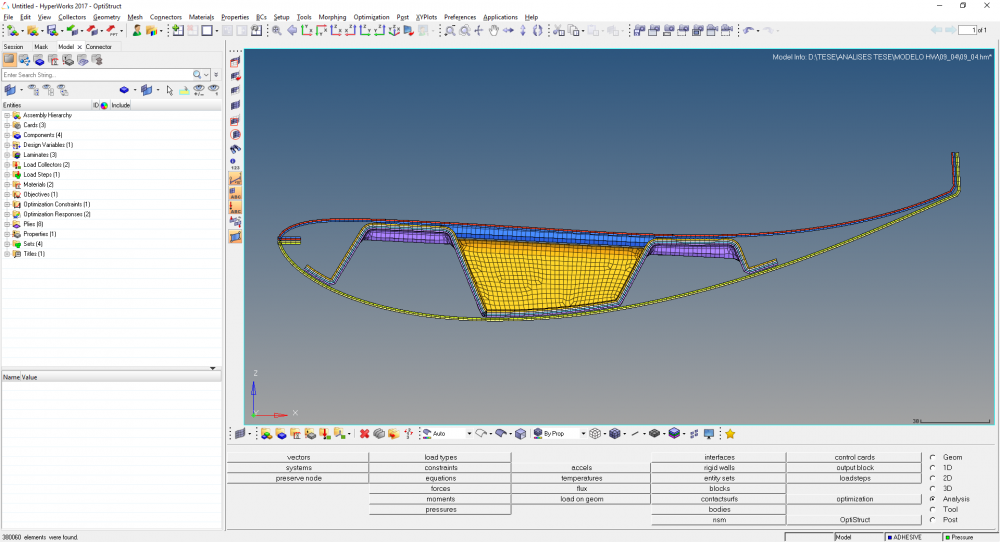

Here you can see the side view, the three elements of the wing with the standard lay up

<?xml version="1.0" encoding="UTF-8"?>

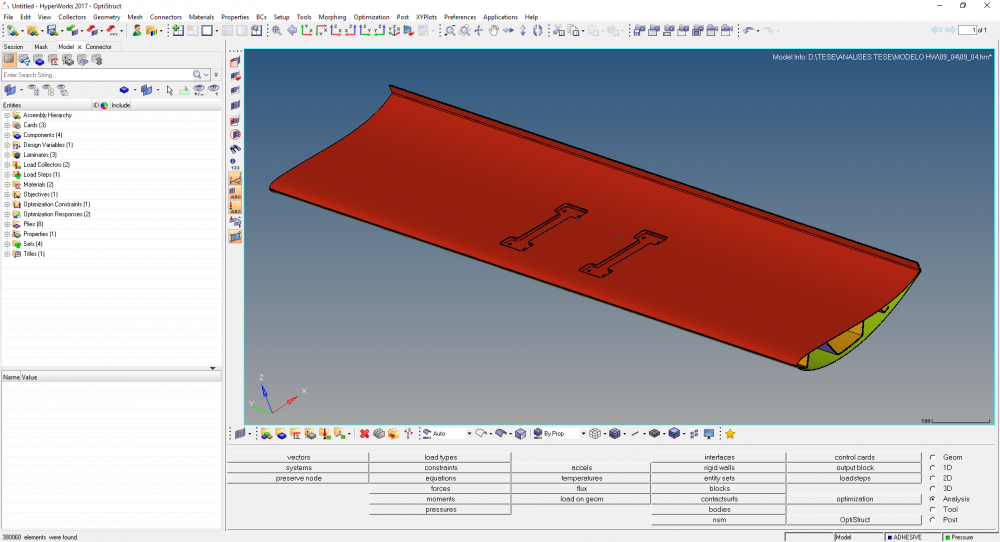

Here you can see the view from the Top

<?xml version="1.0" encoding="UTF-8"?>

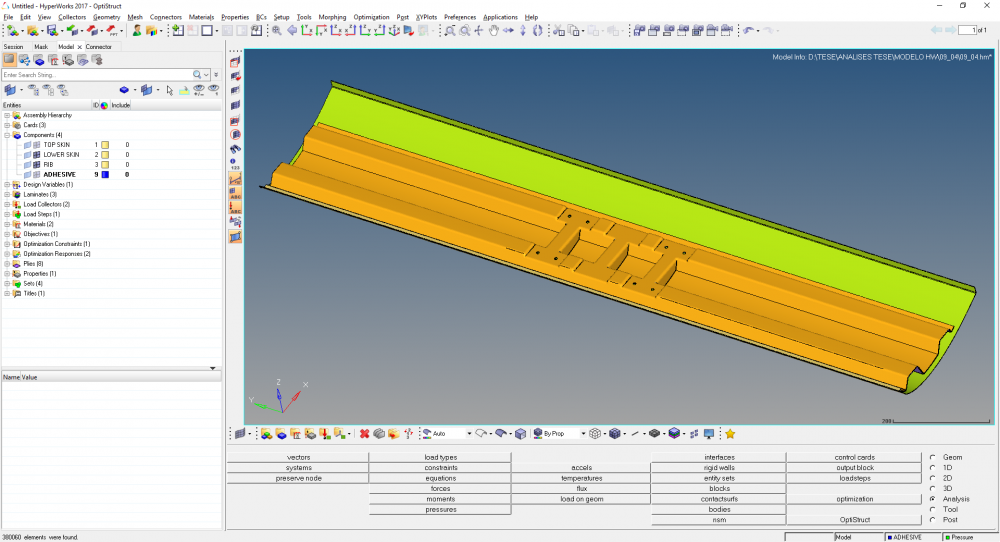

And in here you can see the rib.

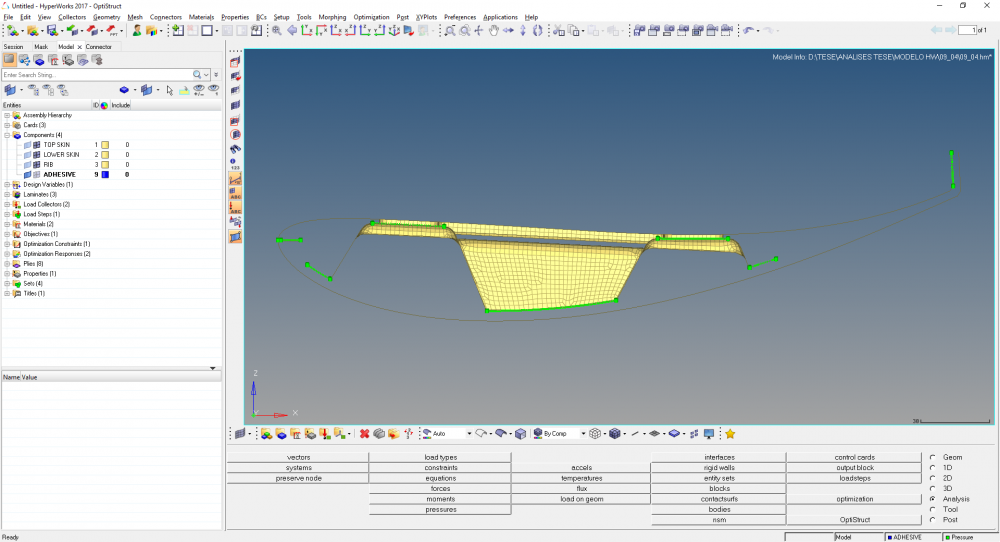

I've modeled the connection between these elements with are connectors of the rigid type:

<?xml version="1.0" encoding="UTF-8"?>

Connector as seen from the side.

<?xml version="1.0" encoding="UTF-8"?>

Connectors as seen from the top.

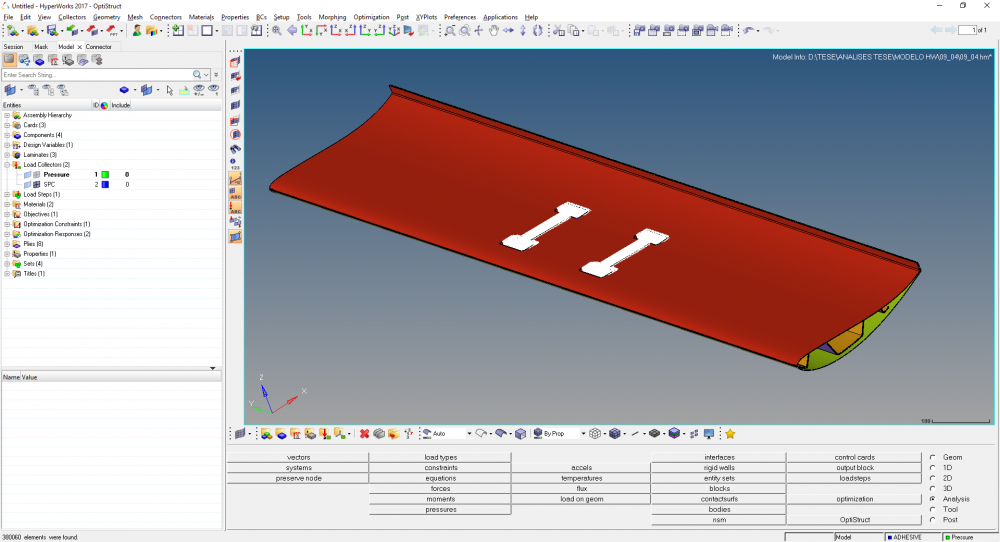

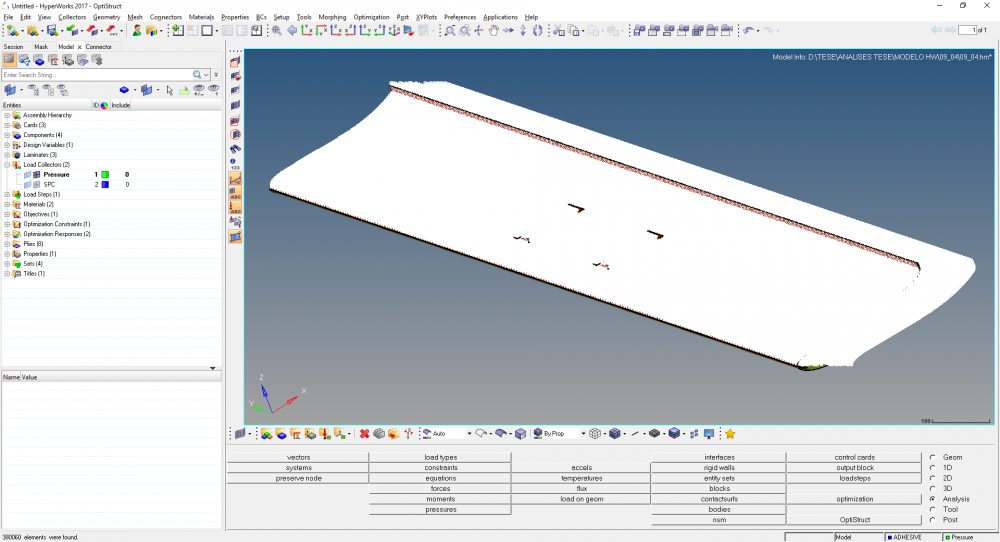

The wing is constrained on the middle on all 6 DOF:

<?xml version="1.0" encoding="UTF-8"?>

And on the rest of the top skin, a 400kg load is applied:

<?xml version="1.0" encoding="UTF-8"?>

I've run the standard analysis and for the general lay up everything seems fine. The deformations, stresses and the failure criteria all sound plausible.

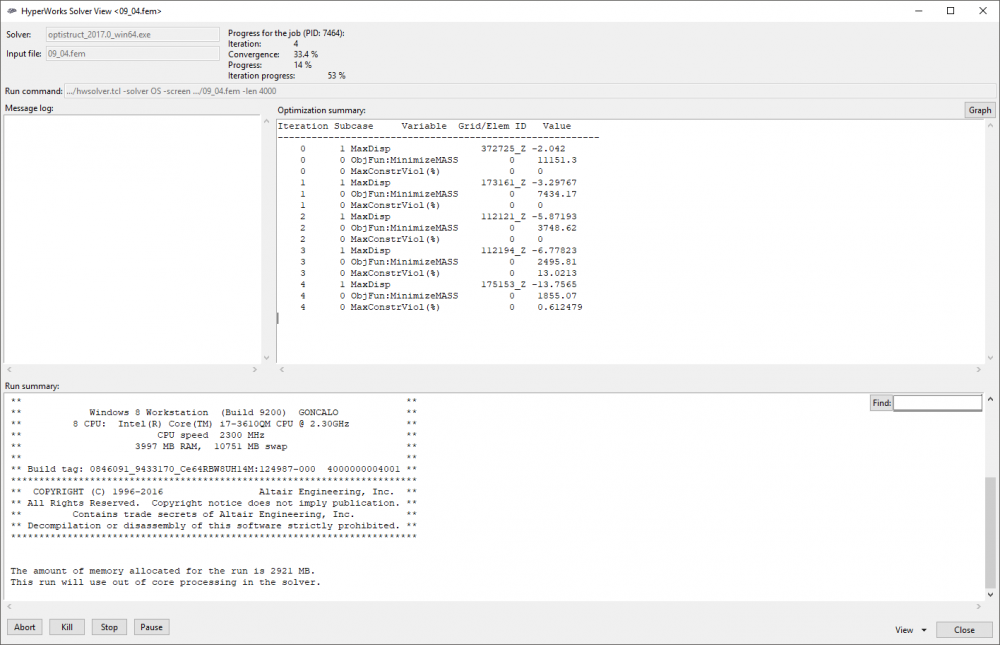

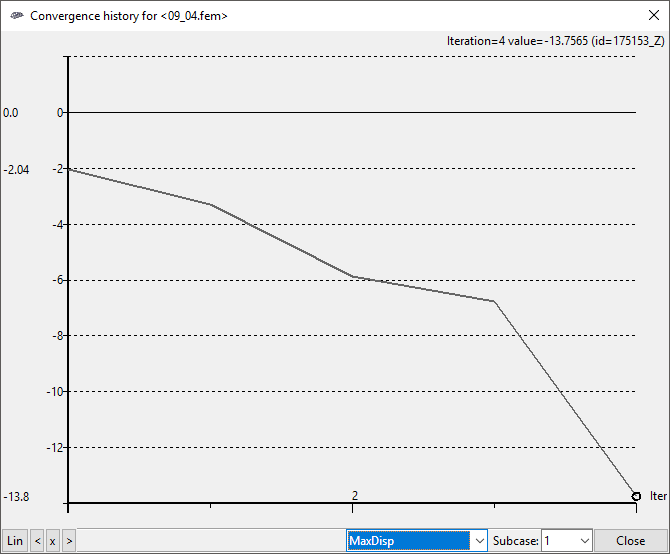

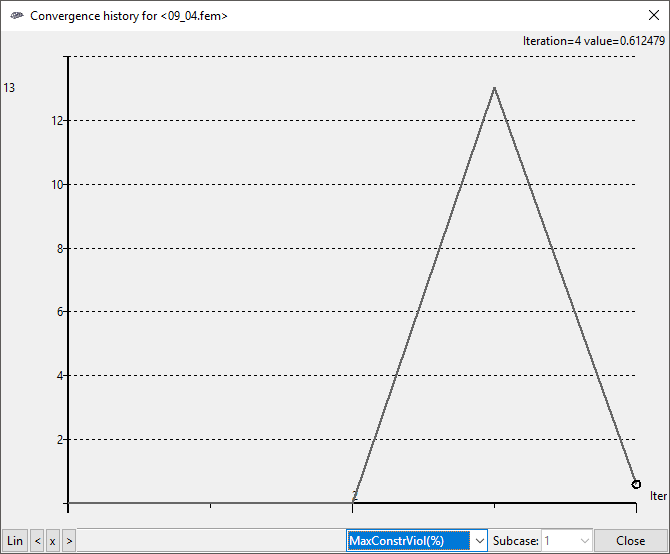

The thing is, when I try to run the first free size optimization a lot of weird things happen:

1 - It takes a LOT of time - for each iteration it takes 30min or more

2 - It starts fine, but then it completely violates my constraints

3 - The % of constraint violation does not match

<?xml version="1.0" encoding="UTF-8"?>

I think I've followed everything as it is supposed, but I'm not getting any decent results...

Can anybody help me?

Sorry for the long post...

Gonçalo Pimenta

PS - The plies shown above are for the general lay up (each ply with .66mm tchickness). For the analysis, I switched to 2mm. On the standard analysis I get 6mm maximum deformation on the wing and for the optimization my constraint is 6mm maximum displacement.