Hello all!

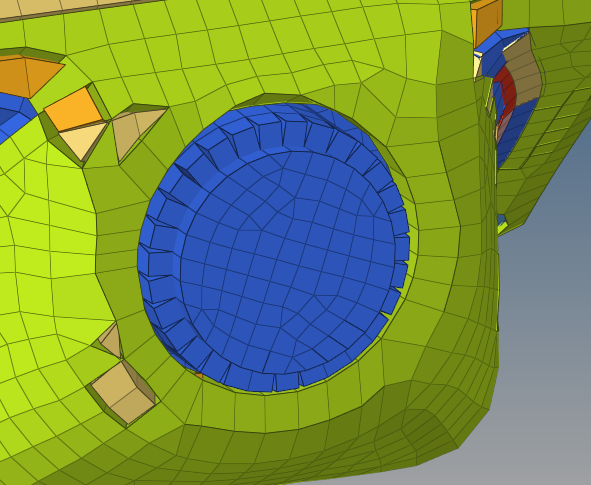

What is the best way for contact interaction with small penetration?

But reaally, i don't see penetration penetration checker doesn't see this too.

but in post processor i have the spurious forces.

i have a manual-crash book. i have tried to use approaches from this book, but i have had fail.

if i do type 7 all settings default i will no contact interaction untill i have large displacement.

i need advice and approach!=)

thanks for help.

Unable to find an attachment - read this blog