Hello Sir,

I'm working on bullet penetration into steel plate.

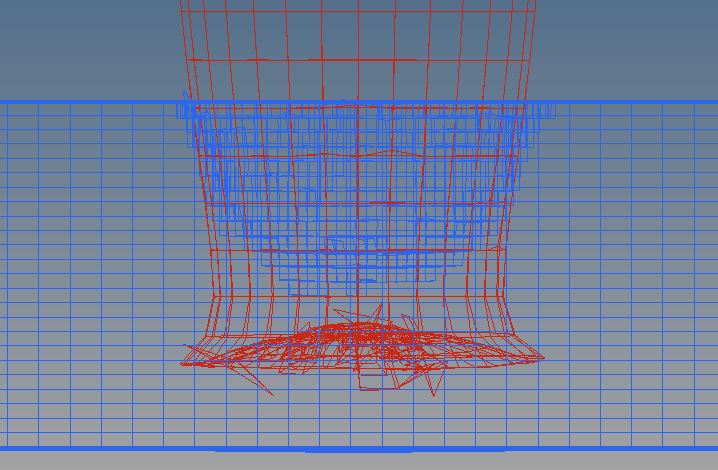

At first contact works beetwen bullet and plate, but next it doens't work so good (picture 1).

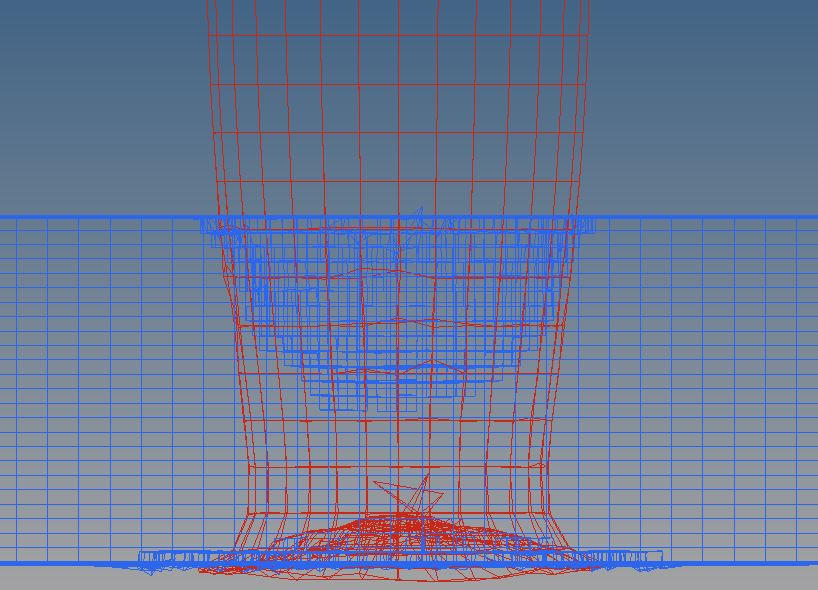

Finally, contact again work (picture 2) and I don't know where is a problem.

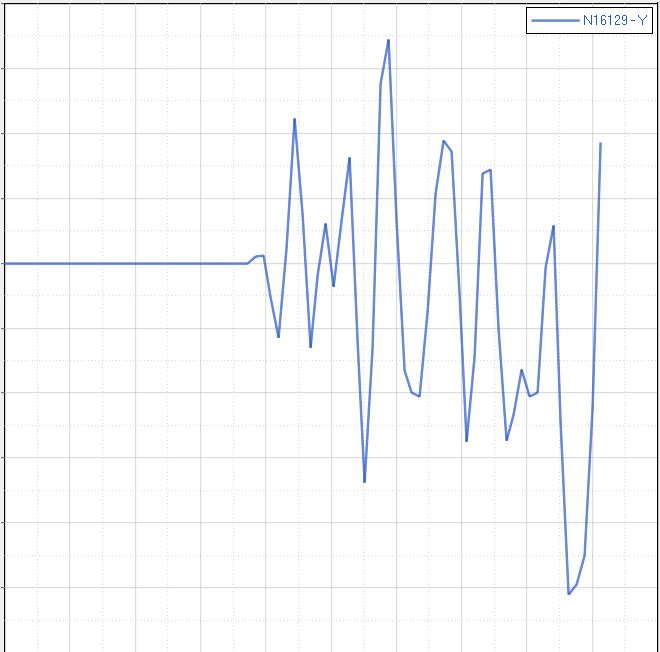

On top of that, the speed of the projectile doesn't decrease (picture 3).

Contact settings:

Type 7

Istf: 4

Igap: 2

Fric: 0.2

Gapmin: 0.1

Inacti: 6

I tried a lot of contact setting, among others:

Type 7

Istf: 4

Igap: 2

Idel: 2

Fpenmax: 0,8

Stmin: 1000

Fric: 0,1

Gapmin: 0,04

Inacti: 6

Iform: 2

but still doesn't work.

Thanks for helping me.

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

Unable to find an attachment - read this blog