Unphysical deformation behaviour for MAT15 and MAT25

Hello guys.

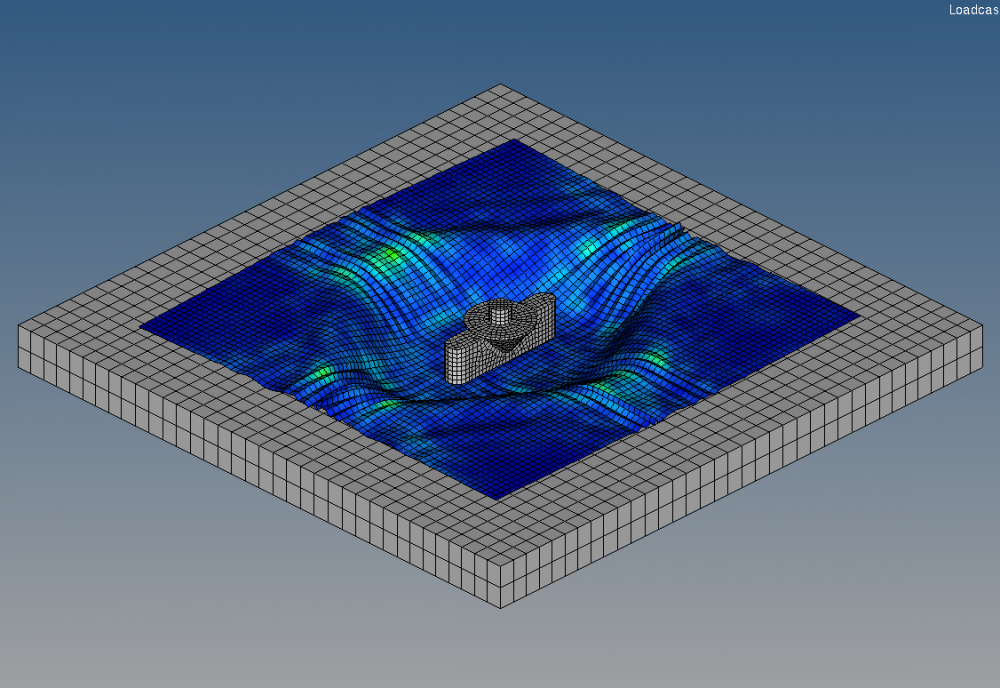

I am trying to model an impact between to bodies. I have modelled the impactor/projectile with solid elements using MAT1 and steel as material and i am trying to model the target plate as a composite shell with either MAT15 or MAT25. The simulation goes fine, no errors or anything like that but the results are simply non physical, in my opinion at least. It appears as if the target plate has no stiffness at all and it behaves like a piece of cloth.. I just cannot figure out what is going wrong. I am attaching 2 images from the simulation setup and results. If anyone needs more info i can happily provide it.

P.S. I am using RADIOSS BLOCK 110, HW12.0, interfaces are of type 7 if thats of any importance. The plate is sitting on a rigid body with a square hole in the center, ofc an interface is modelled between the 2.

Find more posts tagged with

Thanks for your reply tinh. I did not perform any kind of experiments but there are some to be found in the literature for ballistic impact and stuff like that in composite plates and they look nothing like my simulation. I am thinking of switching to solid emelents for the target plate but it makes no sence since my target plate is of small thickness (t = 2% of the plate length)... What material model did you use?

hi,

did you test experiments to correlate with simulation?

i also face the such issue when i simulate sheet metal stamping. the sheet (especialy when mesh size is small) is winkle like cloth