Design Optimization with stress constraints

Hello,

I am trying to optimize the design of a part. The part is subjected to some forces and moments at two locations and it is fixed at some other location.

My intention is to reduce the maximum stress in the component.

I tried topology optimization with stress constraint. But the maximum stress instead of getting reduced, is becoming much more than the earlier value. Please guide me to get the desired result.

Thank you.

Find more posts tagged with

Hi,

Thanks for the help.

Could you please tell me how should I proceed with my problem. What type of optimization should I use for a problem where the main objective is to minimize the maximum stress in the component such that it remains below the yield stress. What can be the recommended objective and constraints?

Hi Priyanka,

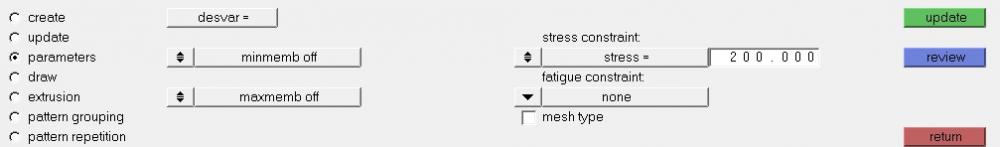

Try to apply Stress constraint on DTPL card instead of DRESP as shown in the image below:

Yes I have applied the stress constraint in the same way. But still I am getting very high stresses.

Priyanka,

If you want to remove material maybe you can start with a topology optimization with minimizing compliance with a constraint on volume fraction.

If you still have high stress after topology optimization, you can then carry a shape optimization.

HI,

So, do I have to define parameters for both topology and shape optimization at the same time?

No,

First try with topolgy with different responses. say for instance, Compliance Vs Volume fraction and check if you are able to hit the target.

If that doesn't help you can go ahead with combined optimization.

Here is one such tutorial for topology+topography.

OS-3100: Combined Topology and Topography Optimization of a Slider Suspension

I am doing the optimization because my component was failing under the given loading conditions. It was exceeding the yield stress of the material. So, I want to reduce this stress well below the yield value. If the weight also can be decreased it is better, but my first concern is the maximum stress. Also, since the component is connected to two other components, my design area is less.

Priyanka,

Please share the model file using the drop box link in my signature below.

Hi,

The stress constraint definition in a topology optimization is a global constraint and does not target local stress concentrations. These areas can be addressed subsequently through size, shape, and free shape optimization or a combination thereof. Artificial stress concentrations are filtered out during topology optimization with stress constraints. These include regions around rigid connections, concentrations due to hard geometric features such as corners, etc.

Stress constraints may not work well in a model where there is a large differential in response values between design and non-design spaces. In these cases, it is recommended to modify the problem formulation to say, compliance based for example

Hence we requested to go for Minimize (weighted / total / regional) compliance with constrained (total / regional) volume / mass fraction.

Regards

Rahul R

Hi Priyanka,

can you remove all the frequency constraints and run a topology optimization with just compliance and volume fraction?

I can see that the frequency constraints are some how violated in the out file.

Hi,

I tried this but still the stress is out of bounds. Can I use a non linear material for topology optimization? since I am having a plastic material. I tried it but the error came like this:

Hi,

I have attached sample decks for material nonlinear optimization using ESLM approach.

Regards

Rahul R

Priyanka,

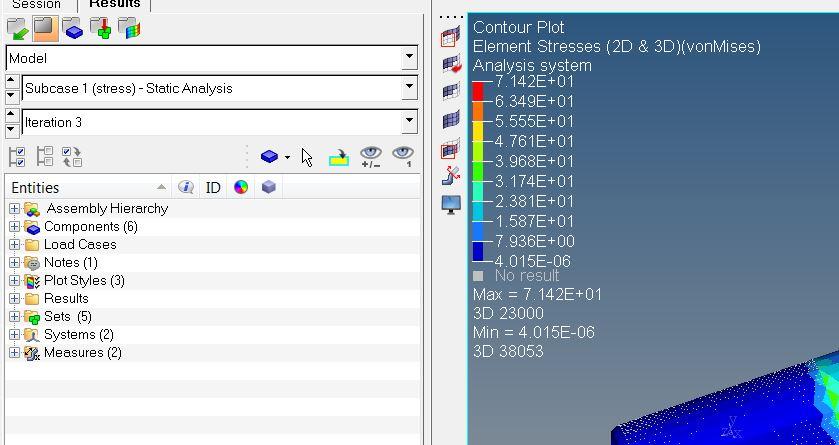

I have used only displacement and VF constraints to check the results and this is what I got.

let me know what do you think about it.

Hi,

Observed the attached files. These are for shape or size optimization.

I want to do topology optimization on non-linear material. I went through the info available on Help.

Please tell is it possible to perform topology optimization for a plastic material component?

Thanks.

Hi Prakash,

I also got the same result. But this stress value is more than the yield strength of the material. It is a plastic.

Priyanka,

what is the yield limit for the material you are using?

You may reduce the stress by doing a shape optimization.

Hi Priyanka,

first, Stress constraint is not recommended for a topology optimization.

The stress constraint definition in a topology optimization is a global constraint and does not target local stress concentrations. These areas can be addressed subsequently through size, shape, and free shape optimization or a combination thereof. Artificial stress concentrations are filtered out during topology optimization with stress constraints. These include regions around rigid connections, concentrations due to hard geometric features such as corners, etc.

As in help:

Stress constraints for a partial domain of the structure are not allowed because they often create an ill-posed optimization problem since elimination of the partial domain would remove all stress constraints. Consequently, the stress constraint applies to the entire model when active, including both design and non-design regions.