3PB Impact Test

Hi there,

I m trying to validate a 3 point bending simulation using a paper which presents both numerical and experimental data. I followed the exact same setup but the resultant force I keep getting is always 20% smaller than the one pretended. I've double-checked materials, properties, contacts and boundary conditions and nothing seems to change. I've tried the validation process with different papers and I always get the same problem. Any idea on what I might be doing wrong?

Thanks,

Find more posts tagged with

I've figured it out. I had inertial problems due to poor sizing of the structure. The paper I am using considers the section's characteristic length as the inner dimension (to which you add the thickness) and not the average one. The section I was using was then undersized and therefore the bending force the beam was able to sustain was lower.

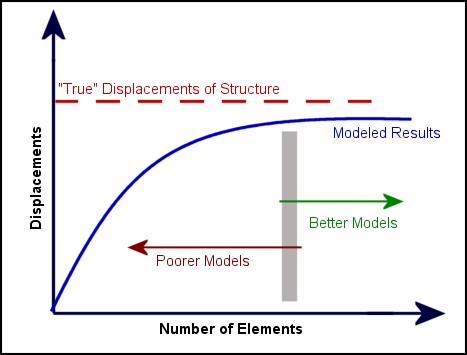

Thanks anyway! Using a more refined mesh is helping me reaching a better solution

Do you try to calculate with different mesh density?