Ddear all

I want to analyze the maximum stress of the bolted joint to check the strength of the structure.

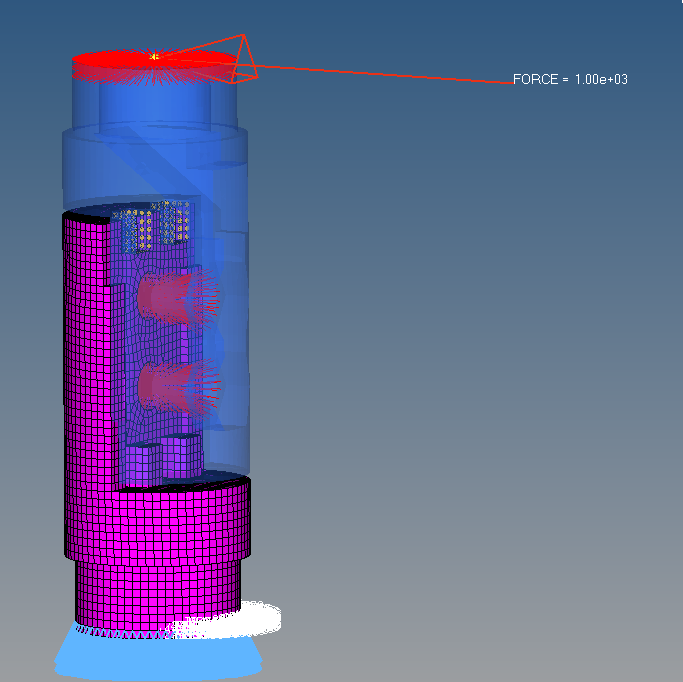

I use the RBE2 element to simulate a bolted connection.

I bound the 6 degrees of freedom at the bottom, built the RBE2 element at the top, and loaded the force of 100N. as the picture shows:

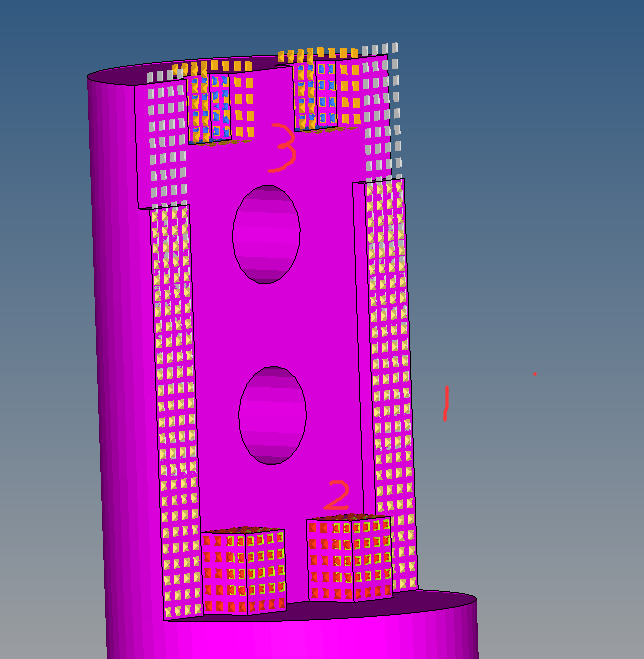

I created 3 contacts to simulate the state of the actual force,

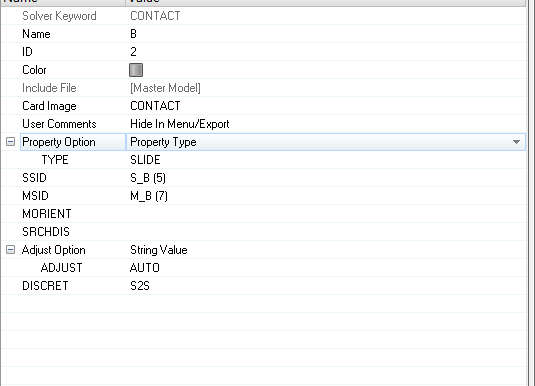

Guānyú jiēchù de shèzhì, rú tú suǒ shì

About the settings of the contact, as shown

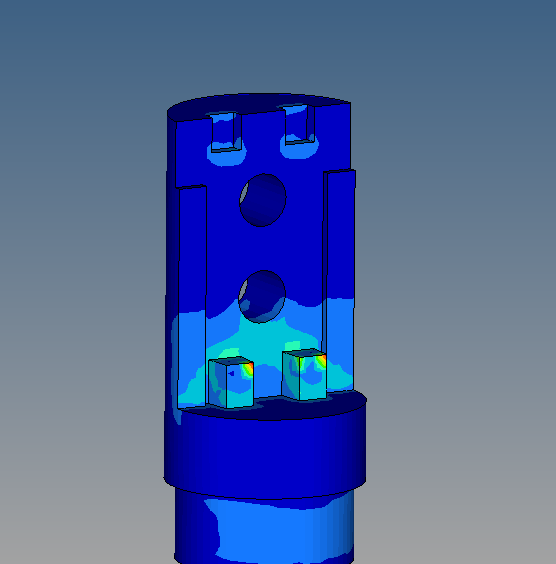

We intuitively analyze that due to the direction of the force, the contact 3 should have a large compressive stress, and the contact 2 should have no too much stress, but as a result, the contact 3 stress is small, and the contact 2 stress is large, which is why ?

So I want to know how I should set it up? Is it wrong with my parameter settings for contact?

Thank you

Unable to find an attachment - read this blog