Hello,

I am trying to simulate the stresses during the chip formation of a turning process for a student project.

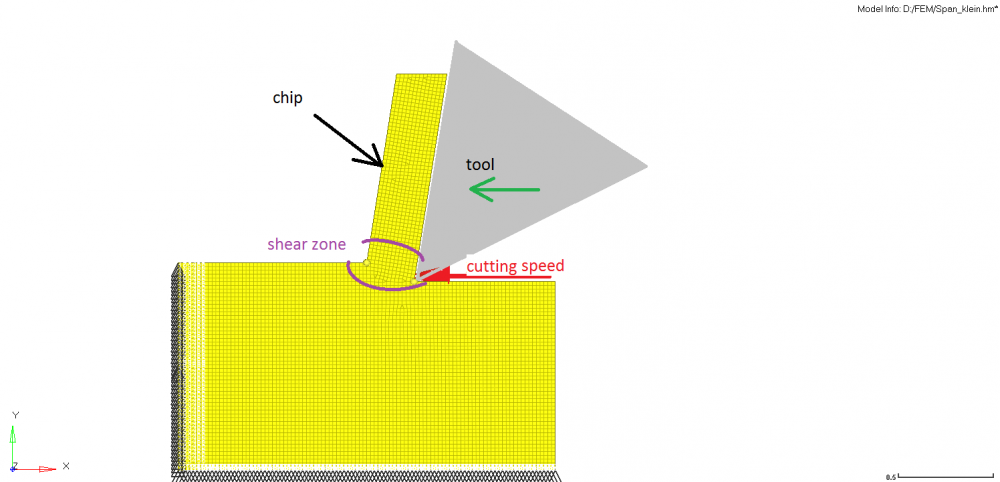

In this process, the tool penetrates the material with a known cutting speed.

For a first run, I took a simplified geometrie of the chip and the surrounding material as you can see in the attached sketch.

My thought was to fix the workpiece with the boundary conditions and set the tool as a rigid body, since I am only interested in the chip formation itself and the stresses in the chip.

At first I started with linear-elastic analysis in Optistruct to et an idea, whre the highest stresses take place. To verify the value of the stresses, I have to implement the failure of he material.

I would like to use a M2- material, since it allows elements to be deleted.

Can you help me with my setup? I tried to use a crash tutorial from altair university to set the model, but I wasn't able to adjust it for my case.

I attached the model file of my last try.

Please take note, that I just started with FE-analysis and probably lack the absolute basics, since I have nobody to ask silly questions in real life.

If it is not possible to run the tool into the workpiece, I could also work with applied forces (I know have some forces from experimental data).

Thank you very much and best regards

Anna

<?xml version="1.0" encoding="UTF-8"?>

Unable to find an attachment - read this blog