Hello everyone,

I have been working on a model on which i would like to conduct a topology optimization study. The model is basically a PU foam block (dimensions lets say length 15mm, width 5 mm and thickness 3mm). The foam has CFRP rovings around it as reinforcement (CFRP in UD thickness 2mm and width 1mm) the rovings are only at two instances on either side of the foam. I have bending load case and would like to run a topology optimization where the Optistruct tool reduces or deletes the foam elements where it is not neccessary thus reducing the overall mass of it. While doing this, i have one of the objectives which i am not certain of defining it in the model.

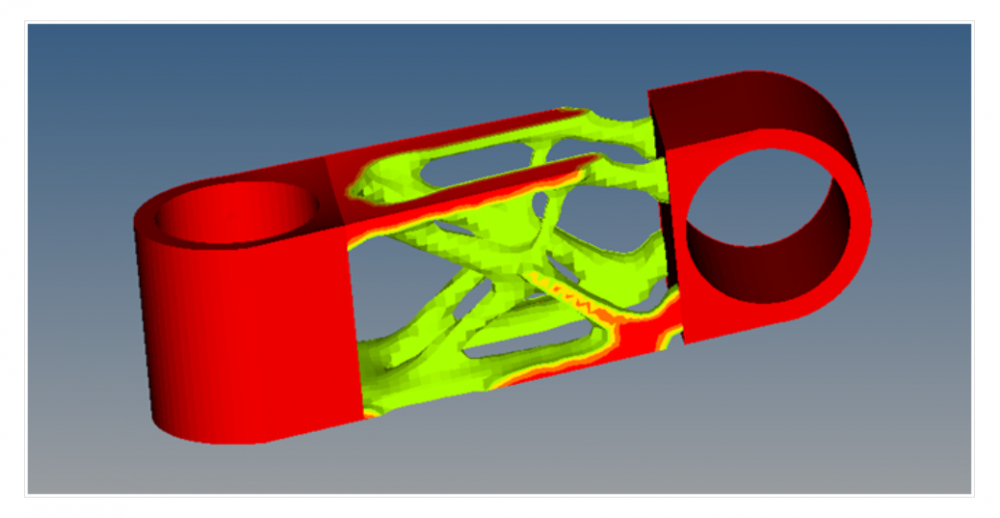

Objective: I would want the solid (foam) elements beneath the CFRP to remain. So the end result should look pretty much like the one in the picture attached.

Could someone please tell me how do i acheive this objective? I ran a sample anaylsis where i used mass of the whole foam elements as a response, the results look fine but not as i had wanted (i.e. in the picture attached)

Please feel free to ask if you need more info. on it.

Thank you and looking forward to hear from you.

Image Courtesy: Altair

<?xml version="1.0" encoding="UTF-8"?>