Altair® EDEM™ continues to set the industry standard for the Discrete Element Method(DEM). Now more powerful and user-friendly than ever, EDEM 2026 showcases our commitment to advancing optimization and simulation-driven design by delivering new key features for physics modeling and customization.

With this latest release, we have introduced the possibility of particle shape distribution with an innovative method to vary the shape of particles so that the true behavior can be better captured. This allows users not only to introduce an initial shape distribution when creating particles, but also to modify shapes during runtime via the Contact Model API, considerably extending the capabilities to capture more complex physics.

The EDEM coupling library is now available to use with Python. This is the next big step in our strategy to democratize DEM for engineers and opens up possibilities for our customers to add more automation and customization capabilities when integrating with Multiphysics & AI.

Here are some more details of the key highlights from this latest release now available on Altair One. You can also take a look at the recording of our release webinar including the Q&A at the foot of this blog.

Innovative Particle Shape Scaling

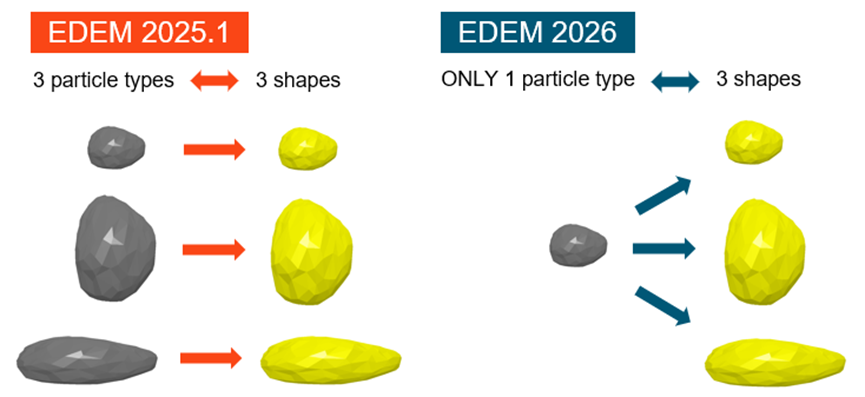

This new capability provides greater control over particle characteristics. Real-world particle materials differ not only in size but also in shape, which can significantly affect material behavior. To address this, we have developed an innovative method to vary particle shape to better capture their behavior. Users can create a range of shapes by varying elongation or flatness, based on a single particle type or template, whereas previously each shape had to be set up individually.

Capturing the particle shape distribution is the next frontier in modeling complex particle materials. This is key for high-precision applications, like battery manufacturing.

Example: Battery Electrodes Calendering

Results: Particle Shape Distribution as Aspect Ratio

Modifying Shapes during Runtime with Custom Models

A unique characteristic of this new feature is the ability to 'stretch' particles during simulation using custom factories and models through our API, simplifying workflows considerably and allowing more complex physics to achieve high fidelity.

Example: Using particle replacement to represent cutting. When a particle is cut in contact with the blade, it is replaced by two new particles, with the length scaled to represent the resulting fragments.

Example: Dynamic morphing based on physics. Each particle represents cookie dough and is slightly deformed (spreads) as it bakes while moving through a continuous oven. This is captured by scaling the polyhedral particle as a function of its temperature in the direction perpendicular to the conveyor belt.

Imported Field Data Extended to Allow Transient Fields

Previously, only static (time-independent) field data could be imported, which limited users who wanted to apply time-varying conditions. Multiple data fields can now be imported simultaneously and organized by time, allowing the simulation of more complex conditions.

A great example is the improvement of our 1-way CFD-DEM coupling, which now allows geometry motion and fluid profile changes during the DEM simulation.

Example - Import Transient Field Data for an Autonomous Mower Design

This improvement will enable users to achieve a faster setup and workflow, whilst also improving accuracy without the additional compute costs previously required to import multiple datasets into a DEM simulation.

1-way Coupling with Simcenter STAR-CCM+

We are pleased to announce our integration with Simcenter STAR-CCM+ by Siemens Digital Industries. Using this new coupling, users can import multiple data sets from their CFD simulations, providing them with more accurate and quicker results. This is our first exciting step in our integration process with Siemens technologies.

Example - Pneumatic Conveying CFD-DEM Simulation

STAR-CCM+

EDEM

New EDEM Python Coupling Library

To enable more users to perform automation and customization when integrating with Multiphysics & AI, the coupling library is now available to use with Python. This is the next big step in our strategy to democratize DEM for engineers.

Example: Apple Ripeness Classifier

The coupling interface itself now enables users to construct coupled fluid - particle simulations between CFD codes and EDEM, coupled simulations between rigid/multi-body dynamics codes and EDEM or simply couple EDEM to other programs written by the user. This gives accessibility to users who want to use python and hence presents the opportunity to achieve more automation and customization within EDEM.

World’s Most Advanced Fibers Model Updated

The Fibers Bonding Model was first released in EDEM 2025. In this latest release, we have made key updates to the model to include additional failure modes, such as combinations of buckling, breakage, and plasticity under different load cases. This is particularly useful for agricultural and health & life sciences applications, offering better insights and greater accuracy in representing fiber behavior and improving performance.

Heat Transfer Model Improvements

This model has been updated to include variable temperature distribution and heat exchange across geometries.

Example: Temperature distribution

These additions extend the capabilities of our 2-way coupling with OptiStruct , allowing now thermal and thermo-mechanical coupled applications. This is a great addition to better solve problems involving particles at high temperatures, where thermal expansion on particles and equipment could have an important role in the overall behavior.

Example: Thermo-mechanical coupling

What else?

Beyond these new capabilities and improvements, this release also brings other important developments, including:

Export to STL: Export Specific Geometries

Users can now select individual geometries for export, rather than being limited to exporting the full geometries.

Additional Analyst Attributes

The EDEM Analyst now includes new attributes in the particle results, like Acceleration, Aspect Ratio, Scale, and Mass Scale.

To find out more about what is new in EDEM 2026, check out the release notes that are available on Altair Marketplace

What’s New in Altair® EDEM™ 2026? – Release webinar recording

What’s New in Altair® EDEM™ 2026? – Release webinar Q&A

Q: Could particle phase change be simulated with EDEM?

A: We do not have any built-in model for this, but you could implement it yourself using our customization tools (API)

Q: For the Particle Shape Scaling, can you set the value/distribution in 3 dimensions?

A: In the particle setup section in EDEM Creator, you could set the distribution by modifying the Particle Aspect distribution in a single dimension. However, the options to define the scaling in multiple directions are available in EDEM's API.

Q: Can you couple the particles with an aspect ratio distribution in EDEM with the Battery analysis tool to measure tortuosity?

A: The Battery Analysis Tool doesn’t support polyhedral particles for now, so it's not possible. Once it is enabled, it will serve as a good example of usage.

Q: Is it possible to model the thermal expansion of particles based on the coefficient of thermal expansion mismatch between different particle materials? Has someone already done that using an API, for example?

A: There is no model directly available for this, but the shape scaling options are available within EDEM’s API.

Q: Do you have the capability, or are looking into coupling DEM with electrochemical modelling? For example, calendar particles/electrode in EDEM then follow that with 3D physics electrochemical modelling of the calendared electrode

A: We don’t have electrochemical modelling with EDEM or our Battery Analysis Tool, but we are looking to use STAR-CCM+ or other tools available with Siemens for this type of analysis

Q: If the length is modified in one direction, can we observe the new length in another direction while keeping the mass constant? Or is it only schematic, and we have to modify the aspect ratios in both directions manually?

A: Yes, the particle’s shape scale can be modified while preserving the particle's volume. You have the option in Creator, or you could scale manually to have this preserved when using it through the API.

Q: With these aspect ratios, can we configure sieve-based particle sizes and use cumulative passing values?

A: The shape scale can be defined as a user-defined distribution, users specify the shape scale and percentage of the material at that scale.

Q: Can the scale factor be altered in all three directions at the same time?

A: Within the API, users can modify the shape factor in all 3 directions independently. In the Creator, just a single direction is selected per particle type.

Q: With the STAR-CCM + EDEM coupling, will it be possible to simulate water + air + particles (SAG mill)? Will it be possible to simulate this coupling with Tavares breakage?

A: Yes, we expect to use the coupling to target this type of scenarios when we have the coupling available to users.

Q: Would the CFD+EDEM coupling all be solved in one UI/solver in 2026? Or do we still need to run the co-simulation?

A: We are developing integrated workflows, like SimLab 2026, but some cases will still require the use of the co-simulation strategy. Especially when more advanced conditions or capabilities from each solver are required.

Q: Is the shape scaling intended to improve computational performance by increasing the interaction contact time? Or is it done to account for changes in particle size during the simulations?

A: This is designed to provide the possibility of more realistic simulations in terms of particle representation, without increasing the computational cost or defining large numbers of particles

Q: Are there plans to work with non-spherical particle breakage in the near future?

A: Yes. We think that the new shape scaling could play a relevant role in how this is implemented in a future release.

Q: How do you envision leveraging Siemens’ AI capabilities in the future to enhance EDEM?

A: This is a strategic line for us and Siemens, so we continue exploring more possibilities to bring AI into our workflows. Combining Altair’s AI capabilities with Siemens existing one will give us a great platform to work with, so expect soon to have news on this.