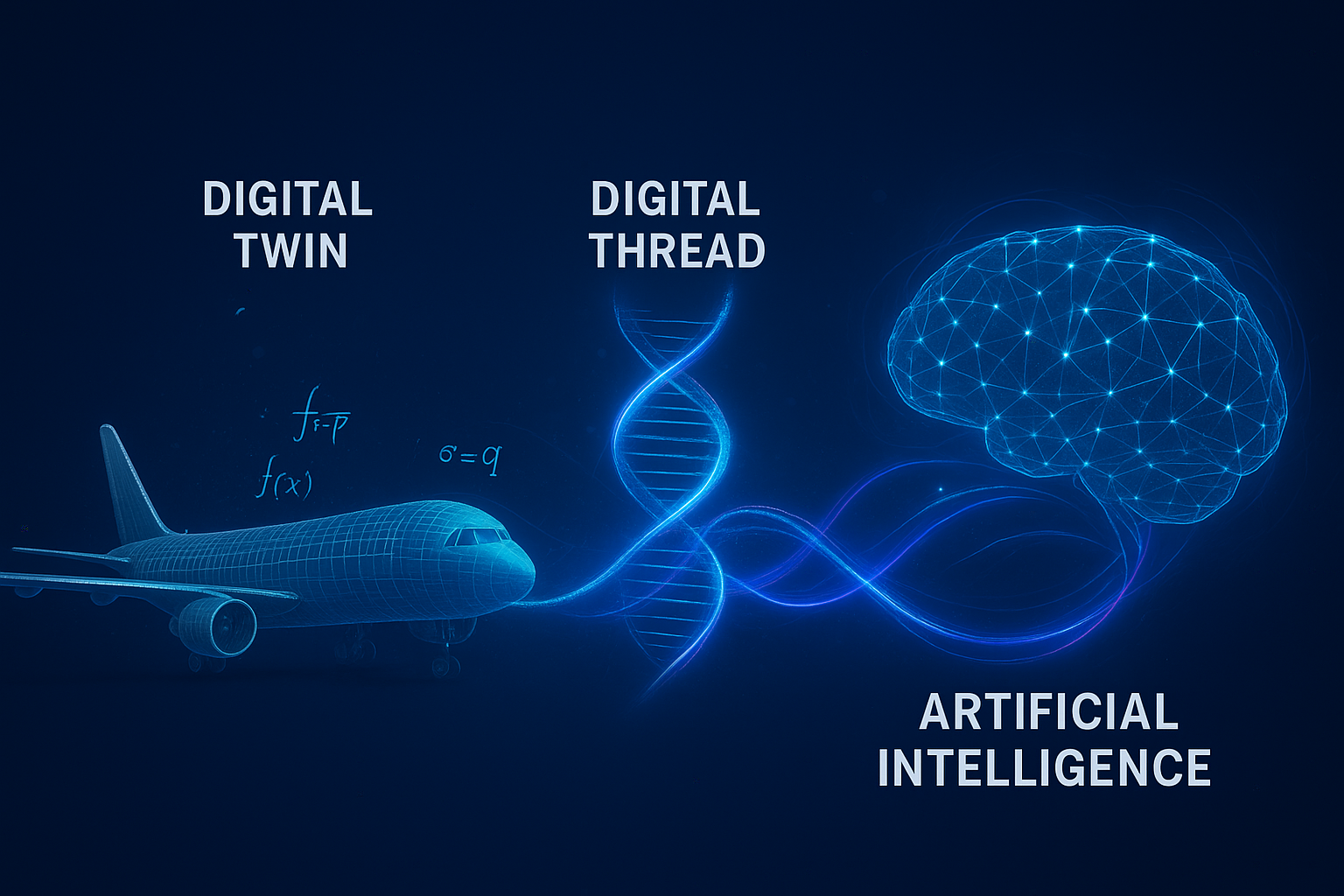

Digital twins: Mathematical Models

Digital twins are virtual models built to support analysis and optimization across multiple stages of the product life cycle: design, manufacturing, operations, and maintenance. By a numerical mirror of the physical system, engineers can simulate “what-if” scenarios, detect potential failures before they occur, and continuously refine performance.

These digital twins deliver tangible benefits: they accelerate engineering cycles (from design to production), shrink time-to-market, lower development and operational costs, and open opportunities for increased revenue. Indeed, companies that bring new products to market earlier can capture sales sooner, especially since novelty often helps with market acceptance compared to older products.

For a more complete overview of strategies, methodologies, and use cases across industries, you can explore Altair’s dedicated playbook.

Digital Twin Playbook

Digital thread: Backbone of the product life cycle

To realize their full potential, digital twins are frequently embedded in a digital thread architecture -an integrated data backbone that links all stages of a product’s life, from concept through retirement. This thread ensures traceability of information across departments and disciplines, giving stakeholders a holistic view of the product, enabling rapid root-cause analysis, feedback loops, and continuous improvement. In complex systems engineering, such traceability is critical.

Artificial Intelligence: Performance Booster

Artificial Intelligence (AI) amplifies the power of digital twins and the digital thread. It enables advanced modeling (beyond conventional physics), automates decision workflows, optimizes data flows, and deepens analytics. An easy way of thinking about AI is as a “performance booster” that can be applied in each phase of the product life cycle to improve performance, reduce costs, and maximize returns.

While AI might appear “optional” today (after all, we managed for many decades without it), those who deploy it will gain disproportionate advantages. In a global, competitive economy, AI is rapidly becoming a must-have rather than a nice-to-have.

That is reflected in the rapid expansion of the AI market. For instance, a recent article of citybiz+ reports that the AI venture capital deals in H1 nearly match 2024 levels - “For the first six months of the year, AI deals were valued at $104.3 billion, just shy of 2024’s full-year level of $104.4 billion”.

A Look to the Future

In the past, analysis and optimization relied heavily on physical prototypes, a process that often took weeks or even months. The advent of simulation -through numerical models now widely known as digital twins - compressed these timelines from weeks to days, delivering significant efficiency gains.

Today, the integration of AI with simulation has taken this leap further, reducing certain types of analysis to just seconds. This capability is fueling growing interest in hybrid digital twins - systems that combine the fidelity of traditional simulation with the adaptability and speed of AI. These hybrids strike a balance between precision and performance, making them a cornerstone of next-generation engineering.

Looking ahead, Product Lifecycle Management (PLM) systems that manage the digital thread will increasingly embed AI to drive automation, oversee complex data flows, and proactively recommend actions. AI “agents” will take on larger roles throughout the product life cycle, making the management of complex, multi-domain products both more robust and autonomous.

Investment in AI research continues to rise, unlocking new techniques and widening applicability across industries. Likewise, efforts to democratize access -through cloud platforms, no-code AI, and open-source tools- are enabling a broader base of companies to benefit from these powerful technologies.

In industrial settings, the combined forces of digital twins, digital thread, and AI are strategic equalizers. They empower small and medium-sized enterprises -typically more agile and adaptable- to innovate rapidly and compete head-to-head with larger companies. A striking example comes from China’s electric vehicle sector, where some manufacturers are bringing new EVs to market in as little as two years, pressuring legacy automotive giants accustomed to far longer development cycles.

For agile organizations, AI is a tremendous opportunity to accelerate growth. For large companies weighed down by inefficiencies and rigid structures, however, could represent a disruptive threat. Without swift adaptation, they risk ceding market share to faster, more innovative rivals.

Ultimately, the technologies themselves are available to everyone. What will separate leaders from laggards is the ability to combine a clear strategic vision with rapid execution. Winning the race requires more than just knowing where the finish line lies -it demands the discipline and willingness to push harder, faster, and smarter to get there first.

To deepen these concepts and discover real-world applications, join our upcoming event dedicated to digital twins

Don’t miss the chance – reserve your spot today and be part of the next industrial wave!

Register Now