This post presents an Altair Radioss solution to simulating hypervelocity impacts on composite laminate. It is based on Meso-scale modeling of hypervelocity impact damage in composite laminates from Aleksandr Cherniaev & Igor Telichev, published in Composites Part B: Engineering, volume 74 (June 2015) [1].

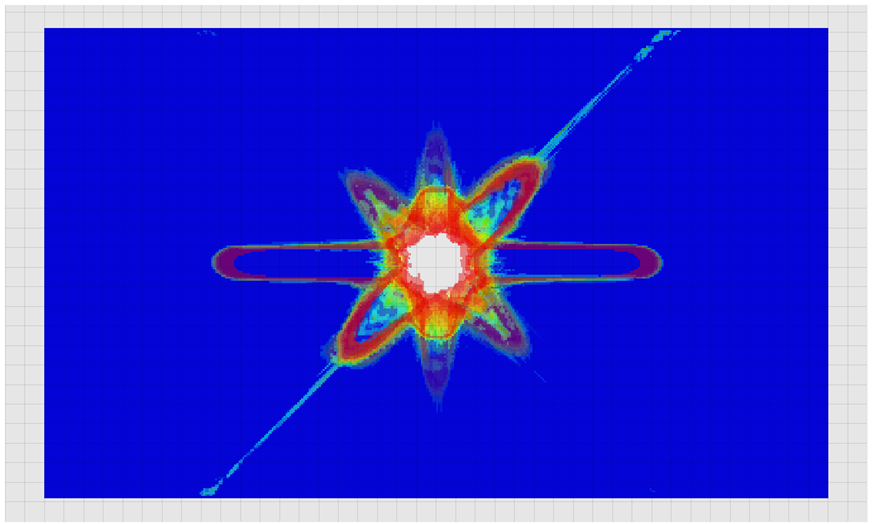

Figure 1: Bullet impact on Composite laminate (UKC#4, 123J)

Please note that the purpose of these analyses is not to exactly reproduce the results from the reference article, but to show how to model such applications using Altair Radioss.

Figure 2: Bullet impact on Composite laminate, section view (UKC#4, 123J)

Material laws and failure criteria used in the Radioss analyses are different from the ones used in the reference article, especially for the composite plies and the resin layers.

The models have been setup for Altair Radioss v2025; some outputs require v2025.1.

The 2 attached models correspond to the 2 cases exposed in [1]:

Case | Bullet Diameter | Bullet Mass | Bullet Velocity | Kinetic Energy |

|---|

UKC#4 | 2.0 mm | 0.0133 g | 4.66 km.s-1 | 123 J |

JSC#2 | 2.0 mm | 0.0133 g | 6.75 km.s-1 | 258 J |

Table 1: Hypervelocity impact cases

Figure 3: Damage through Plies and Resin Layers (UKC#4, 123J)

Here are a few points of the modelling used for these analyses:

- Bullet is modelled using SPH

- Composite plies are modelled using solid (hexahedron) elements

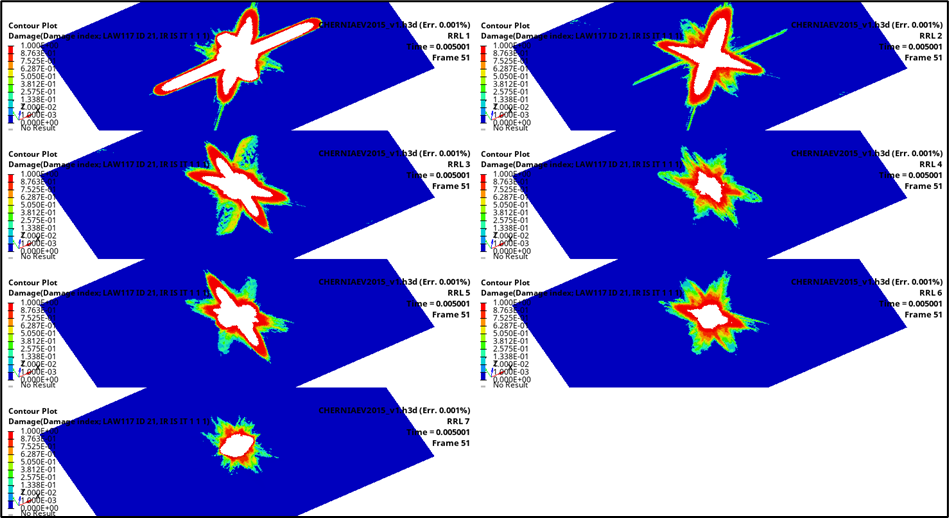

- Resin Rich Layers (RRL) are modelled using cohesive (hexahedron) elements

- Contacts are defined as interface/INTER/TYPE7

- 1 interface between bullet and all the plies of the composite laminate

- 1 interface per ply between the ply and its closest neighbours

- Output of failure modes for theOrthStrain failure criterion is defined using /H3D/SOLID with FAILURE option (compatible with /FAIL/ORTHSTRAIN in v2025.1)

Figure 4: Damage through Resin Layers (UKC#4, 123J)

Figure 5: Delamination Pattern on Resin Layers (UKC#4, 123J)

More details can be found in the attached pdf document.