Hi there,

I am currently doing a project where I use both HyperWorks and Abaqus softwares. After carefully (and reviewed several times) pre-processing two identical models in both softwares with similar number of nodes and elements and the same load cases, I simulated both of them and found some insufficiencies that would like to understand:

In a certain load case, I utilized a kinematic coupling constraint (abaqus) and a rbe2 (hypermesh) to generate a constraint between an independent node that was subjected to a certain load and the respective set of dependent nodes properly defined in the structure shell region. After applying the same load and the same boundary conditions, I noticed some varations between the magnitude displacement values - abaqus got a displacement of around 8 mm while the optistruct obtained a value of around 3 mm (very strange given the same load case etc). After analysing the results, I came up with the idea of filter the results legend with little variations to understand how the displacement values would change between the application pad region and the near locations:

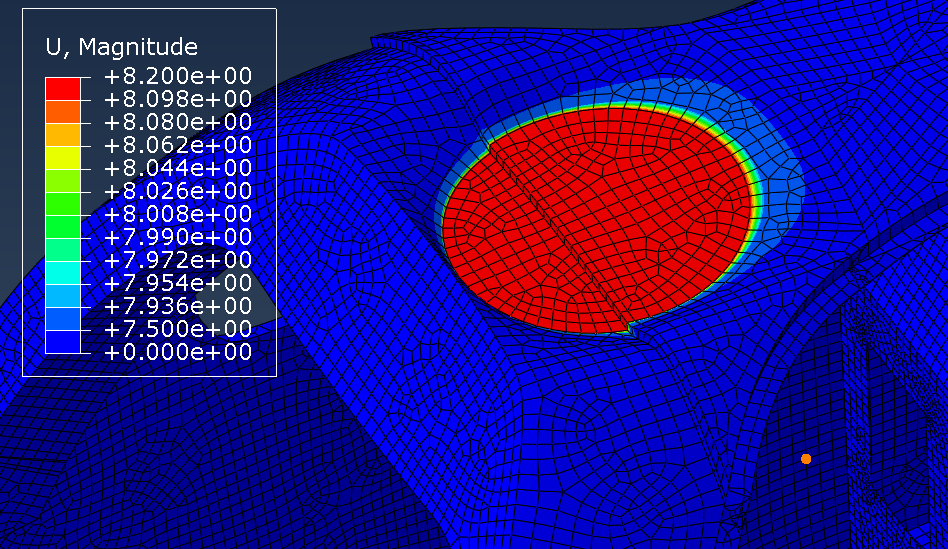

ABAQUS presented this variation:

A very abrupt variation between the pad itself and the near regions. A change of almost 1 mm of magnitude with 1 cm of distance from the pad.

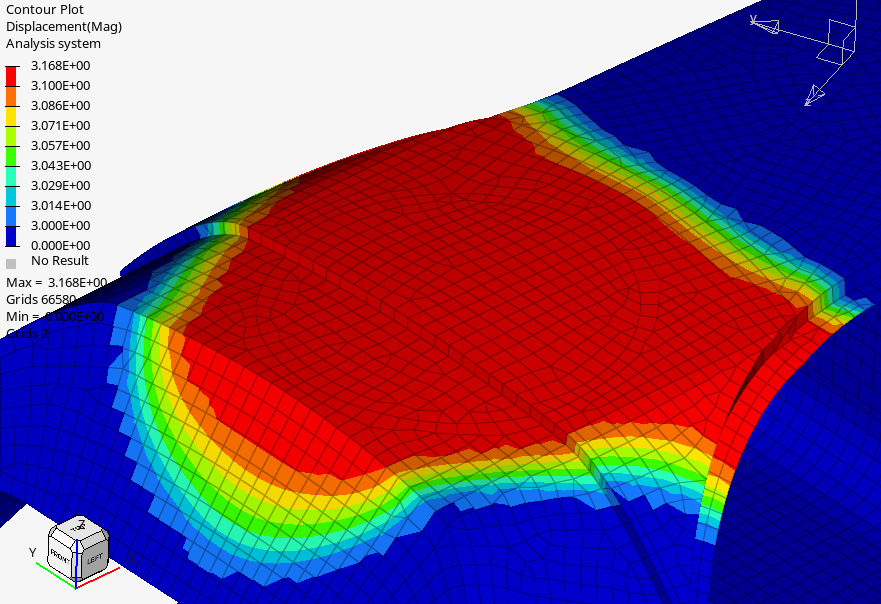

HYPERWORKS presented these results:

A larger distribuction of the displacement, meaning an obvious lower maximum displacement value. You could understand the circular pad by the mesh and understand that a variation of 0.06 mm of magnitude requires a distance of around 3 mm from the actual pad.

Given that, I would like to know if anyone could help me understand the reasons for these differences and a way to minimize these variations.

Thank you in advance!