Introduction

Effective tractor-implement systems are necessary for cultivating healthy crops. Traditionally, improving tractor-implement performance has relied on field testing – a process which is time-consuming, weather-dependent, and costly. In this article, we explore how MotionSolve (Multibody Dynamics) and EDEM (Discrete Element Method) enable engineers to simulate the performance of tractors and their implements, serving as a powerful alternative to field testing. Critical performance metrics such as drawbar pull, wheel slip, soil compaction, and tractive efficiency can all be predicted in a virtual environment allowing engineers to make informed decisions.

Draft Force – The force required to pull the implement (e.g. Disk harrow) through the soil. This directly informs engine power requirements and fuel consumption.

Drawbar Pull – The maximum force available to the tractor at the hitch for pulling implements and towing.

Wheel Slip – The ratio of ideal vehicle velocity to actual vehicle velocity resulting from a loss of traction. Wheel slip is related to efficiency and can indicate soil damage.

Soil Compaction – EDEM simulates the interaction of the tires and any implements with the soil, showing how the particles are compacted. Excess compaction degrades the soil making compaction an important indicator of performance.

Tractive Efficiency – A measure of the engine power converted to useful work calculated as the ratio of drawbar power to wheel input power. A valuable metric indicating the efficiency of the system with greater tractive efficiencies indicating a tractor requires less fuel for a given task.

Simulation is particularly valuable for performing virtual prototyping. The tractor or implement design can be modified and analyzed in a simulated environment to provide rapid insights without the cost and time associated with building prototypes. This allows engineers to tweak implement design, simulate performance, and measure outcomes leading to rapid iteration towards an optimal design that meets all requirements.

Beyond rapid prototyping, simulation allows engineers to simulate a wide range of conditions to understand performance in all situations. For example, new soil models can be tested to simulate different soil conditions like dry gravel or wet clay. Engineers can use these simulations to identify potential scenarios where the tractor does not meet requirements and then modify the design to improve performance. Finally, simulation has the added benefit of providing quantitative information in areas where it is difficult or impossible to measure in the field. This aids engineers as they make comparisons between different designs, allowing decisions to be based on data.

The Multibody Dynamics Model

The multibody dynamics model captures the dynamics of the system. The model is created following a standard process.

- CAD of the tractor and implements are imported into MotionView.

- Bodies are created for each of the CAD graphics.

- Points and joints are created to connect each of the bodies.

- Motions and forces are applied to joints to drive the system.

- Tire models are added where necessary to accurately simulate the interaction with the ground.

This model was built to be modular. The implement, a disc harrow, was built as its own system which can be enabled/disabled with a click. Users can import new implements and connect them to the tractor. This enables users to evaluate the performance of multiple implements with one tractor model.

Alternatively, the implement systems can be exported to new MBD models and hooked up to different tractors with a few clicks. This allows users to quickly explore the performance of an implement with different tractors.

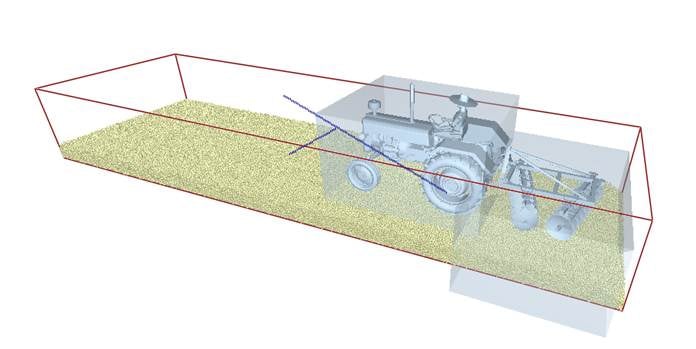

The Discrete Element Method Model

The Discrete Element Model (DEM) handles the tractor/soil and implement/soil interactions. The first portion of the process requires defining material models based on the required application. EDEM includes the generic EDEM material model (GEMM) library which simplifies the material creation process. The library addresses one of the greatest challenges with bulk material simulations, defining an accurate material for realistic particle interactions. The library contains thousands of models for soils, rocks, and ores suited for applications at various scales in the construction, mining, and agricultural industries.

Once a material model is defined, the material can be created using a material factory. Then, the tractor and implement geometry can be imported into EDEM by enabling the coupling server in EDEM and using the EDEM tool in MotionView. After importing the geometry, materials should be defined for each component of the tractor which will interact with the bulk material. Materials which don’t interact can be set to virtual to speed up the simulation.

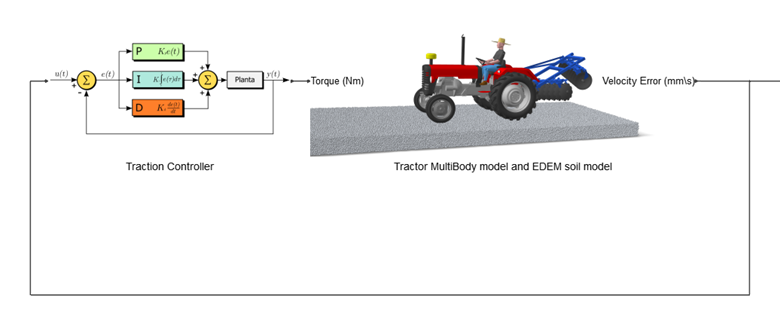

The Traction Controller

The tractor’s controls are modeled using Twin Activate, a tool for modeling and analyzing multidomain dynamic systems using a block diagram interface. The controller receives the error between the target velocity and actual velocity from the tractor MBD model. Then, feedforward and feedback PID controllers compute the engine torque which will minimize error. Additional features, including saturation limits to represent physical limitations in velocity of the engine, are incorporated in the model to increase fidelity.

Software Requirements

MotionView

MotionSolve

Twin Activate

EDEM

Model Files

Tractor Model Zip

Running the Model

Disk Harrow

- Open the Tractor_Model.mdl in MotionView.

- Open Tractor_Soil.dem in EDEM.

- Enable the coupling server in EDEM.

- Run the analysis in MotionView.

Results

Disk Harrow

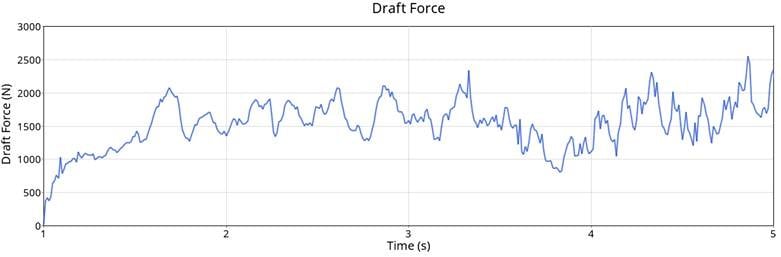

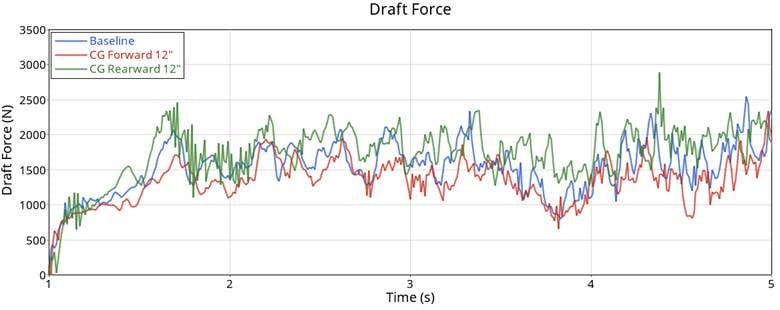

The tractor requires a draft force of approximately 1500 N to pull the disk harrow through the soil. The draft force increases as the CG is moved rearward. This is expected as the vehicle has more traction on the rear, driven wheels allowing the velocity controller to apply more force to the implement throughout the vehicle’s acceleration.

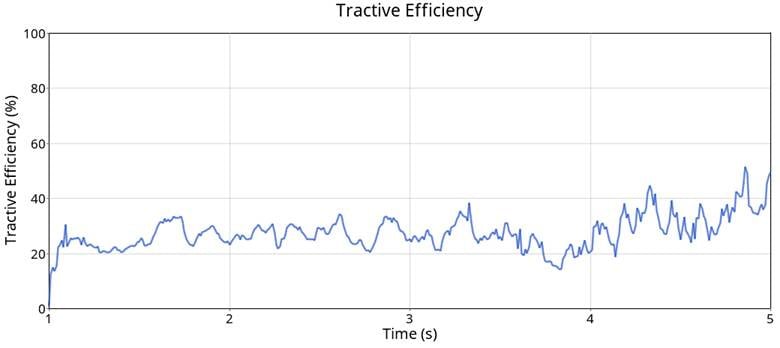

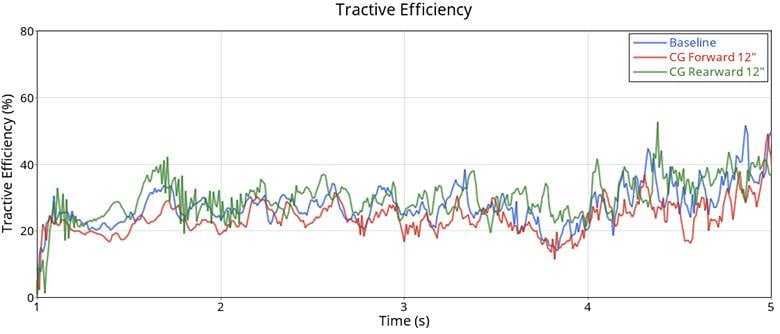

The tractive efficiency of the tractor is the ratio of the drawbar power to the power produced by the engine at the drive axle. The simulation shows the tractor has a tractive efficiency of approximately 30%. The tractive efficiency or ratio of drawbar power to engine power increases as the CG is moved rearward. This is expected as the vehicle has lower slip and fewer losses with more traction on the driven wheels.

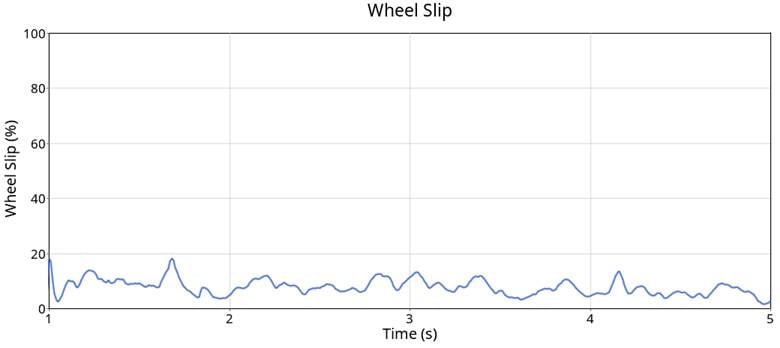

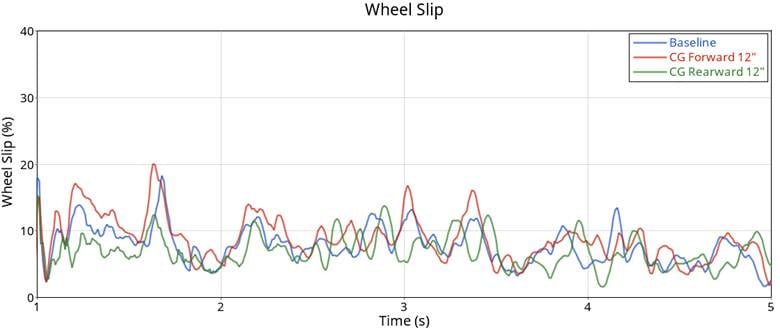

The wheel slip shown is the average slip of the rear wheels. As the center of gravity of the tractor body is shifted rearward, the initial wheel slip decreases. Once the tractor reaches a constant acceleration, the wheel slip is approximately equal between different CG locations. The tractor’s wheel slip is approximately 10%. Slip is a measure of the relative motion between the tire and the ground. High slip or lots of relative motion means the tire is sliding across the ground, which could potentially damage the soil. The low wheel slip is ideal, because it reduces the chance damage occurs to the soil.

Conclusion

Simulation is a powerful tool to complement field testing for understanding tractor-implement performance. A virtual environment enables quick design studies, a process which would be costly and time-consuming with physical prototyping. Key performance indicators including wheel slip, tractive efficiency, drawbar pull, and draft force can all be pulled from the model to understand the holistic performance of a tractor-implement system, allowing engineers to make informed design decisions.

Authors

John Dagg, Systems Engineering Intern

Original Model Authors

Stefanos Stathis, Systems Integration Team

Livio Mariano, Systems Integration Team