Hi everyone,

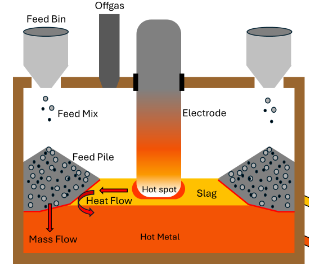

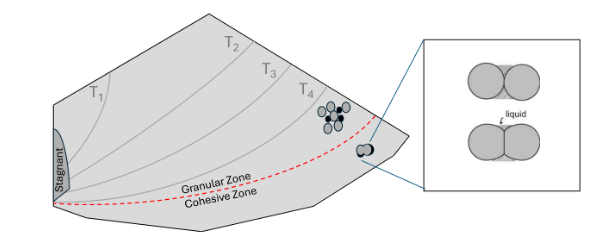

My questions ia about choosing the most suitable modelling approach. I’m currently working on an EDEM simulation where DRI particles fall into a slag and molten metal bath inside a furnace. The particles form a feed pile that slowly melts to produce slag and hot metal. My goal is to accurately simulate the cohesive zone at the interface where the cold feed pile contacts the hot slag (or metal) bath.

This is the zone where particles start melting, stick together, and are eventually removed from the simulation. A diagram of the situation and the expected feed pile shape (with cohesive zone) is provided below

Current Setup:

I’ve developed two API plugins:

- Buoyancy Plugin: Defines slag and metal bath regions. Particles inside these zones experience buoyancy and drag forces, effectively creating a simplified fluid–solid interaction without CFD.

- Shrinkage and removal Plugin: Tracks the residence time of DRI particles inside the slag bath (below the slag surface). Once particles exceed a threshold residence time, they shrink, and are removed upon reaching a minimum size. This mimics the melting behavior inside the cohesive zone.

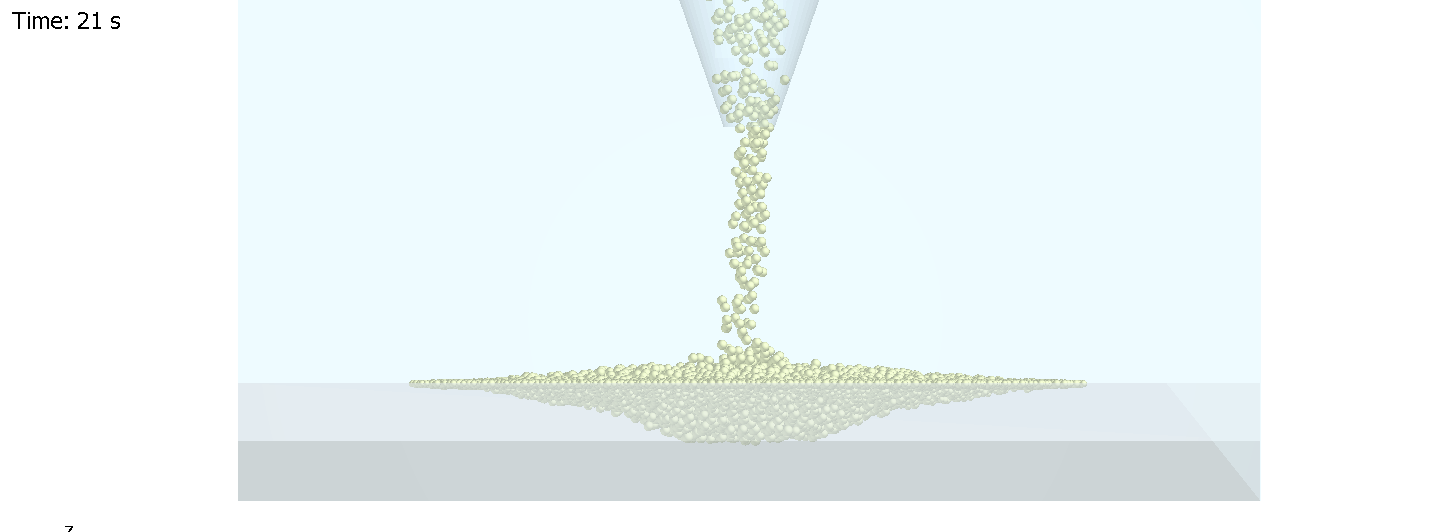

During simulation, a steady-state pile shape emerges as the feed rate balances with the removal rate. Below is a snapshot of the pile with the slag in light grey and metal in dark grey.

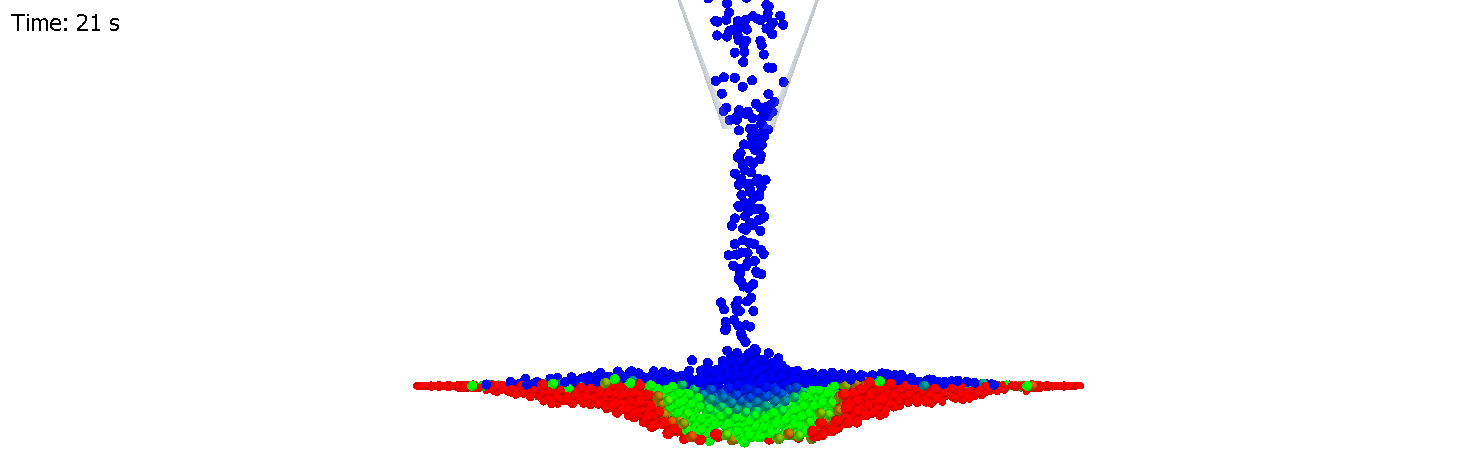

The region where particles have resided in the slag for over 2 seconds is visualized as the cohesive zone. These particles are colored red in the image below. This is the region I aim to model as a physically cohesive zone inside EDEM.

The shrinkage and removal plugin already works accordingly. The red depicted particles start to melt and are removed when a certain diameter is reached (naturally at the outside of the pile). My next step is to incorporate cohesive forces between these particles to more accurately mimic the cohesive zone.

What I want to model now:

Inside the cohesive zone, particles should:

- Feel cohesive forces, even if not in direct contact.

- Still be able to move slowly relative to each other, so that particles can gradually reposition and migrate through the cohesive zone. This is important because, as particles at the edge of the cohesive zone melt and are removed, new particles must be able to move in and replace them to maintain a steady pile structure.

- Behave as if they are surrounded by a viscous medium or thin glue-like film. (Partial melting / sintering)

In other words, particles in the cohesive zone should remain clustered and resist spreading due to cohesive forces, but not become completely fixed. They should still be able to slowly move and reposition, allowing them to progress through the zone and replace melting particles at the boundary.

What I tried:

I created a custom Variable Cohesion plugin (based on Linear Cohesion V2), where cohesion is applied as normal force proportional to the effective contact area A = π * R * δ if their residence time is above 2 seconds. However, this is not producing the desired behaviour:

- Cohesion is only active during direct contact

- Cohesion is weak (even for very large surface energy density) as the overlap of particles is also very low

- Contact is easily broken

- The pile collapses, and no cohesive zone shell is formed keeping the pile together

Thus, this model does not accurately mimic the cohesive zone.

What I am considering next

I am evaluating two alternative contact models to base my next plugin on:

- Liquid Bridge Model:

- Allows cohesion at distance (rupture length), not just on contact.

- In my mind a liquid bridge seems to mimic the sticky, viscous nature of the cohesive zone. (I does not model viscous forces really)

- Concern: This model only implements a normal force which is very similar to my current cohesion plugin. I am worried if forces will be strong enough and if behaviour will be different from my current implementation.

- Bonding V2 Model:

- Particles form bonds with normal and shear stiffness, and breakage thresholds.

- Bonding is strong enough to form this very cohesive zone / solidified shell.

- Concern: the bonds may be too rigid, potentially preventing particles from shifting or repositioning as they melt and new particles move into the cohesive zone.

- The default Bonding V2 model only forms bonds once at the moment of contact. In my case, I plan to modify the logic so that at every time step, the plugin checks whether two particles are close enough and at least one of them has a residence time above 2 seconds. If these conditions are met and the particles dont have a bond already, a new bond would be created, even if a previous one was broken. By assigning low bond stiffness, the model could allow some relative motion while keeping particles connected. Although Bonding V2 does not include a built-in rupture distance, but I feel like this could mimic the same behaviour as the liquid bridge model. I dont know if it will work as I imagine.

My question:

Which contacct model is best suited to simulate the partially molten / sintered behaviour inside the cohesive zone?

Should I use the Liquid Bridge model, Bonding V2, or are there better alternatives?

Any suggestions are very welcome. Thanks in advance for the help!

Note: Please dont worry about how to integrate the cohesive model work with the shrinkage plugin. I am purely interested in what contact model conceptually is best suitable to mimic the cohesive zone behaviour. I am sure this can be handled.

Kind regards,

Jan-Thijn Wijnker