Hi Altair Support Team,

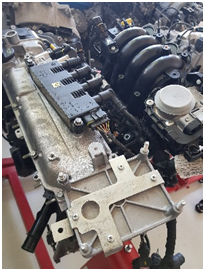

I'm a student working on a university assignment, and I'm trying to perform topology optimization on an automotive bracket that's mounted on the engine in Altair Inspire. I've hit a roadblock and would really appreciate your guidance.

My objective is to reduce the bracket's mass while ensuring a minimum natural frequency of 400 Hz, using the "Maximum Stiffness" objective. For my assignment, I've followed these steps in Inspire:

- Assigned material properties (I'm using Aluminum 6061-T6).

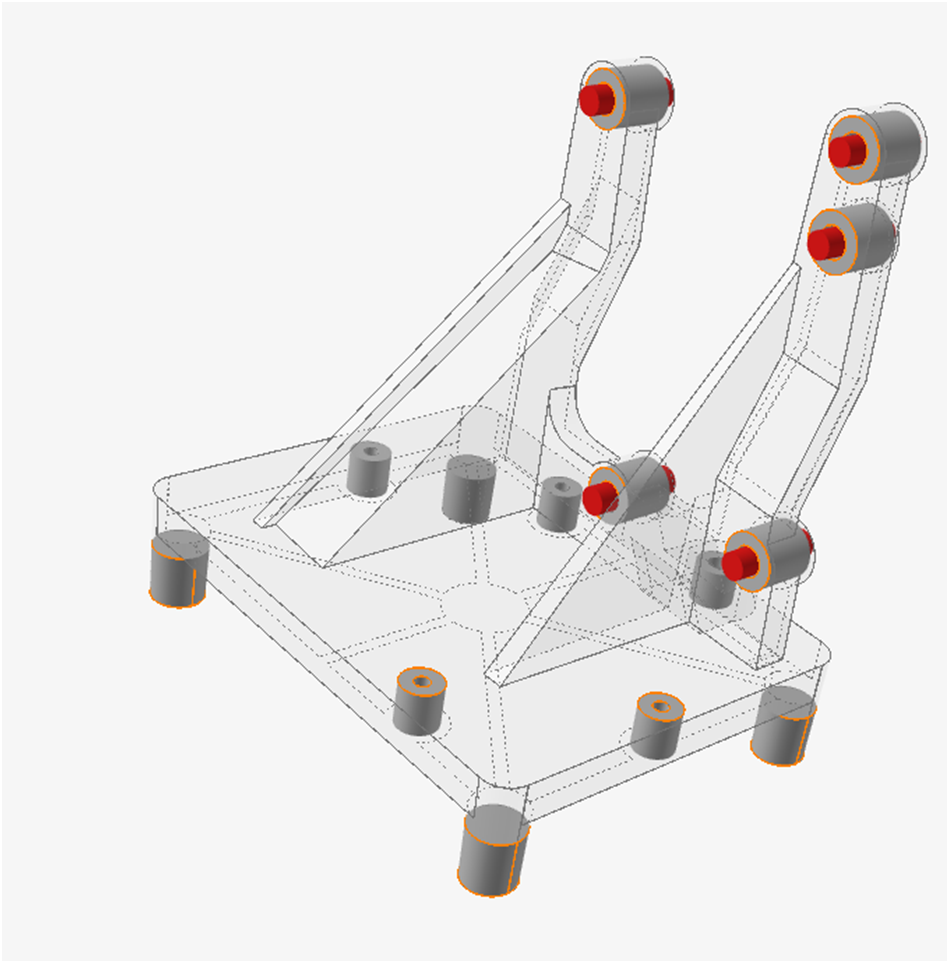

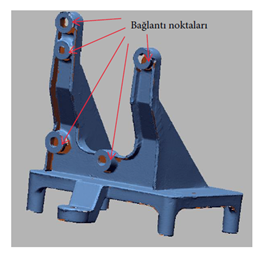

- Defined the support/fixture points for the bracket (specifically where it connects to the engine).

- Specified the design space for the optimization.

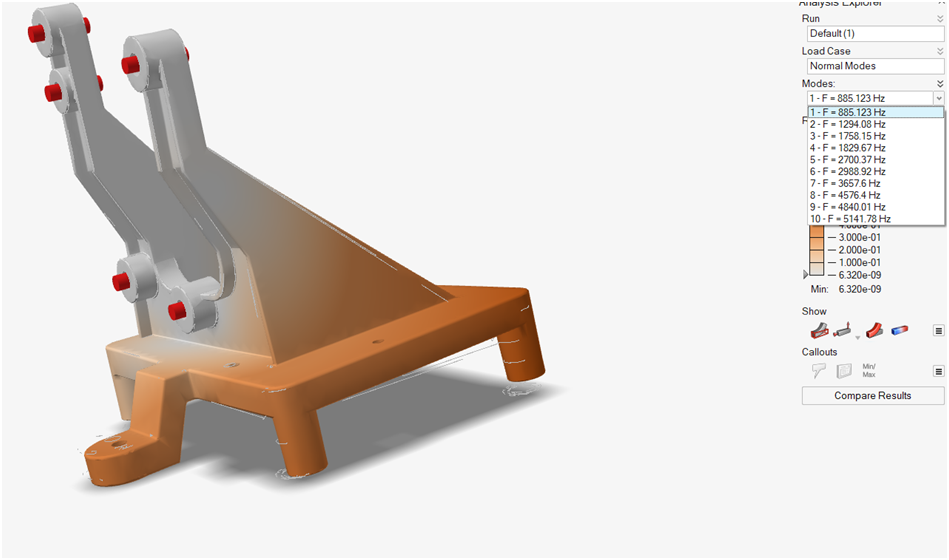

- Performed an initial analysis.

However, I'm stuck at the final step: I'm unable to run the topology optimization. Inspire seems to require a load definition, which feels counter-intuitive for a purely frequency-driven mass reduction goal where the primary focus is on modal behavior rather than a specific static load. Given this bracket's function on the engine, its dynamic behavior is crucial.

Could you please review my approach and advise if I'm missing any crucial steps or if there's a recommended workflow for frequency-constrained mass optimization without a static load input? Your expertise would be incredibly helpful for my academic project.

Thanks for your time and support!

Best regards,

Uğur Ata Korulareli