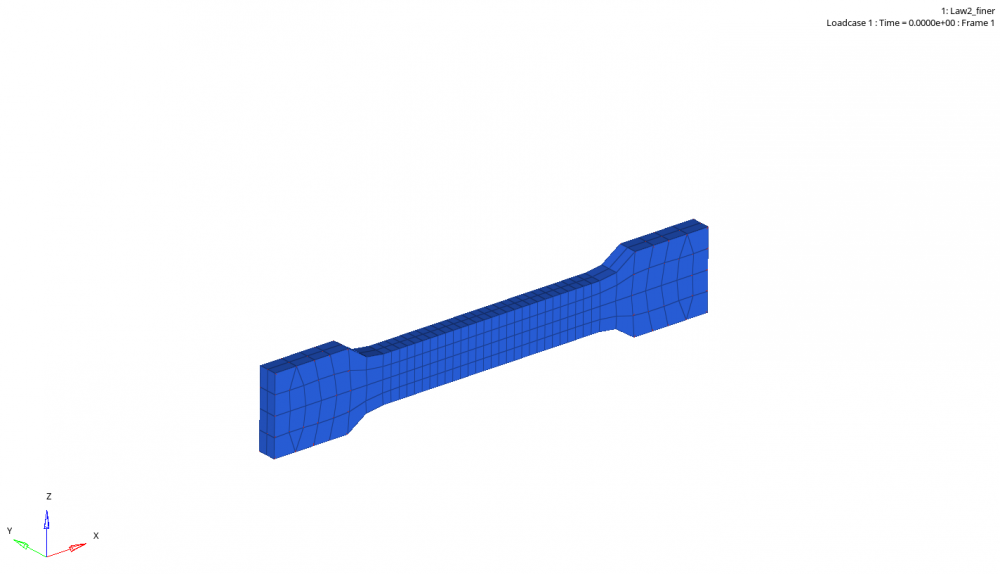

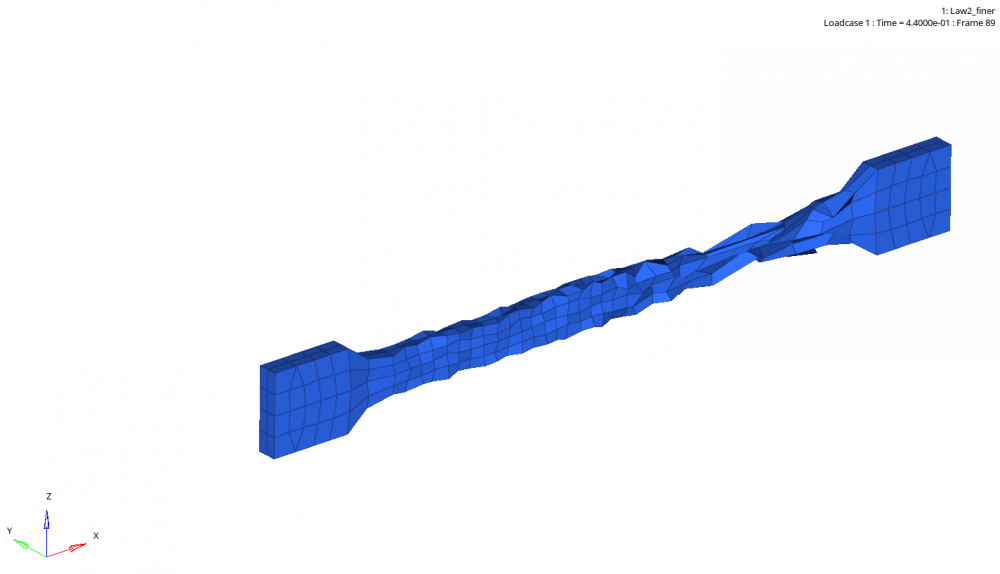

I am trying to model a rubber material that has 300%+ elongation capacity. I don't need to model the rupture mode, just the fact that it can deform elastically and return to its original shape. I tried with LAW2 and LAW42 but my solid elements (BRICK) just seem to explode when I reach close to 100% elongation. I tried different ISOLID (1,14,24), but I always get the same result.

Any advices welcome, thanks. Images of model and .rad, .out below.

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

Unable to find an attachment - read this blog