Hi All,

I seem to have a recurring issue and it doesn't seem to make much difference if I use S2S or N2S.

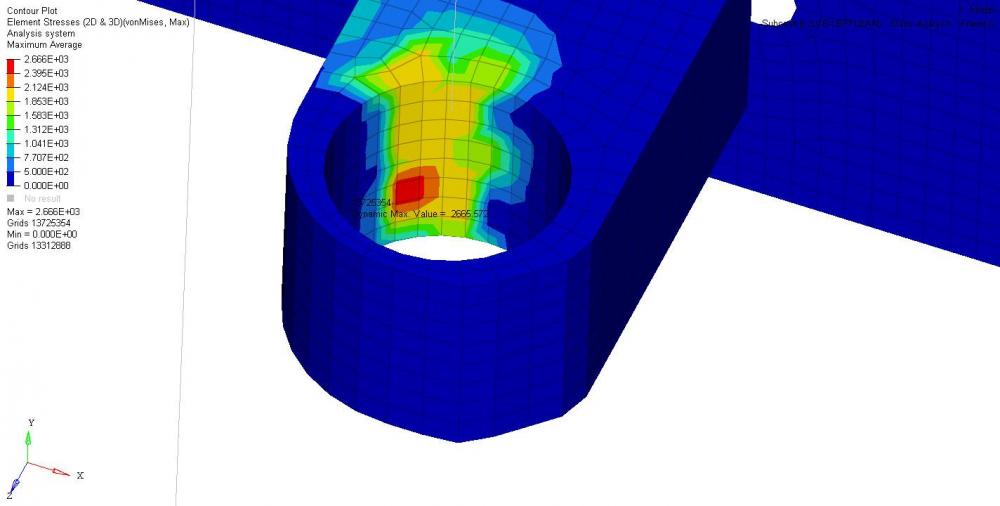

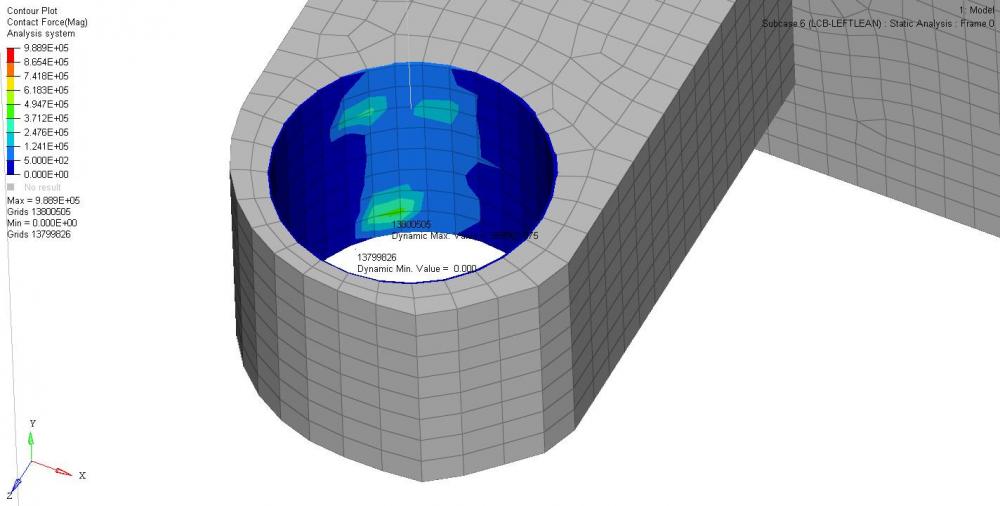

I have a number of very similar models, all set up the same way and I would only expect a mild difference in stress distribution and contact. What I get is with some of the loadcases I have an extremely high contact force. Now I've encountered this before and have needed to switch to gaps but this time I really do need the contact forces exported.

Here are some notes.....

NLPARA = NINC 10

PARAM = CNTSTB

Contact card = Adjust = auto, type = slide, MORIENT = Norm.

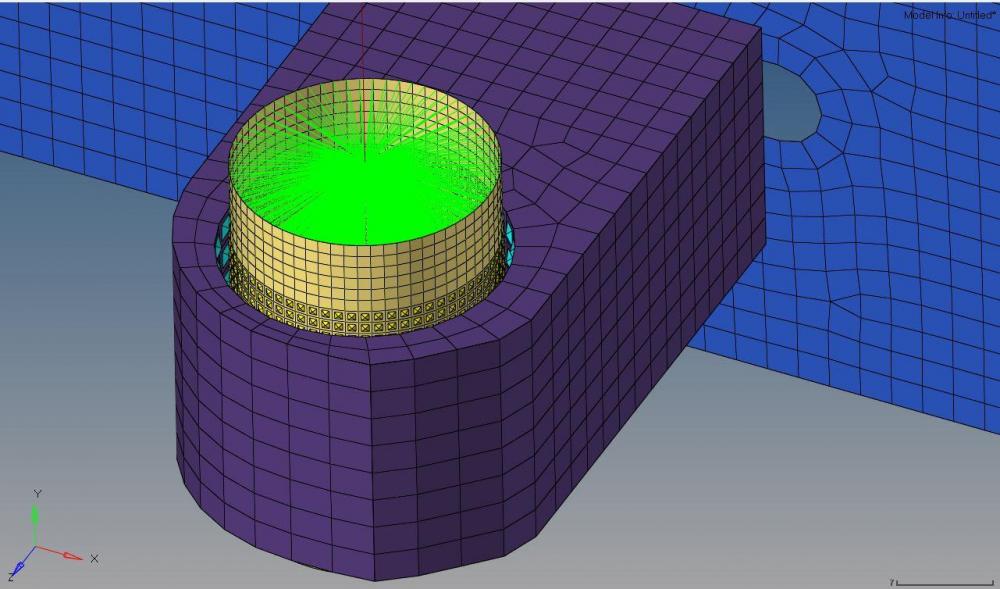

In general, slave contact surface is smaller mesh size.

<?xml version="1.0" encoding="UTF-8"?> <?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

I've added some images....

<?xml version="1.0" encoding="UTF-8"?>