In any electronic product development cycle, one of the important aspects is to design the product to be compliant with the many electromagnetic compatibility (EMC) and Electromagnetic interference (EMI) standards that specify maximum allowed emissions.

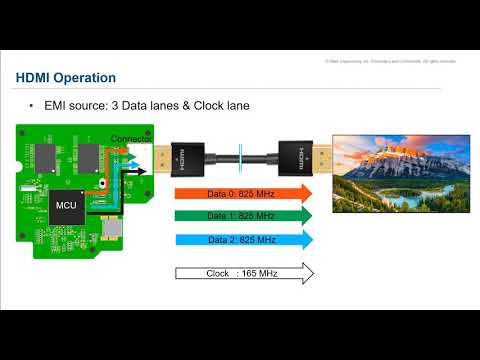

One of the issues found when tracking down a radiated emission problem is cable radiation. A common topic always found in discussions regarding cable radiation is emissions due to High-Definition Multimedia Interface (HDMI) cables.

As more and more consumer electronic and commercial products are introduced with HDMI cable connections, the resulting EMI issues related to HDMI cable emissions continue to be problematic for product designers and EMC engineers. It is very common for a product to fail the radiated emissions test due to one or more added HDMI cables. Failure during radiated emissions testing delays or prevents the final qualification of the designed product. This will eventually affect the time it will take for the product to reach the market.

Since cable harnesses or assemblies are usually passive devices, the radiated energy emitted from cable assemblies can be mitigated by several techniques. We discuss one such technique in this article.

Shielding cable bundles or individual differential pairs and conductors is an extremely effective way to address radiated emissions noise. This method also reduces the level of disruptions in cable signals due to external interference.

There are different types of shielding that range from a woven over braid, to copper tape, and metallized foil wraps. All have their unique benefits so it is best to review the design goals to come up with an ideal shielding strategy. The challenge with this method is to select the right shielding for a particular application. It is impractical to physically model prototypes of every combination and perform measurements. This would escalate the time and cost to design the product.

Here, we focus on how to reduce the time and cost by virtually validating an HDMI cable design using Altair® Feko® simulations. This approach allows EMC engineers to predict the emitted radiations of multiple types of shielding available. It also helps engineers to make an accurate decision on various design aspects, such as thickness of the shielding and materials to be used. This approach saves time by avoiding significant re-work during a product development cycle.

To learn more, this video takes us through a three-step workflow to compute radiated emissions from an HDMI cable. Download the attached PDF file (for slides) and zip file containing the model files.

https://www.youtube.com/watch?v=XABkYMWm7_M

https://www.youtube.com/watch?v=XABkYMWm7_M