Composite materials increase their prevalence in various applications day by day due to their interesting properties. In addition to unidirectional layers, which are widely used in aviation due to their high strength and low weight, woven fabrics are very popular in the automotive industry due to their collision resistance and formability. However, as in sheet metal forming, when composite structures take form, different mechanical properties are encountered in different regions.

In deep drawing and laying processes, especially in prepreg composite structures consisting of woven fabrics, different alignments can be seen in the drawing lines during the deformation of the warp and weft yarns.

Deformation in woven fabrics: before and after deformation

It has been proven by tests that different forms are formed after forming in composite structures laid at different angles. In this case, including the change in elasticity due to angle change between weft and warp structures (warp-weft) caused by forming in composite materials, will increase the accuracy of the simulation result.

Parts formed after deep drawing according to the composite layer placement at different angles

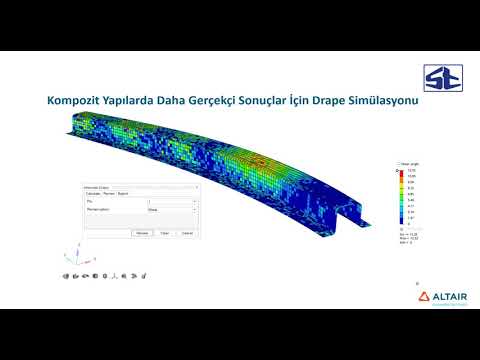

Kinematic Drape includes specific methods to estimate the manufacturability of composite parts with challenging shapes and accurately reflect material orientation for structural analysis. Drape simulation predicts how the element orientation and hence the mechanical properties of the layer will change as the layer is placed in the mold.

Altair HyperWorks (new generation HyperMesh) offers users Kinematic Drape features to model composite structures in a short time, view the composite structure created, and reflect the elasticity changes caused by production in simulation.

Ply-based composite modeling in HyperWorks interface followed by Kinematic Drape

The angle difference between weft and warp threads of the woven fabric after Kinematic Drape and the table containing these values

As a result of the simulation performed with the created boundary conditions, the analysis results with and without Kinematic Drape are as follows.

Analysis results of models with and without Kinematic Drape simulation

You can review the video below for the process steps. Don't forget to subscribe to ST Engineering's YouTube channel.

https://www.youtube.com/watch?v=TdoZIXxo-9Q&feature=emb_logo

https://www.youtube.com/watch?v=TdoZIXxo-9Q&feature=emb_logo