- RESEARCHER

- Behzad Soltanbeigi

- INSTITUTE

- University of Edinburgh, UK

- DEPARTMENT

- Infrastructure and Environment

- SUPERVISOR

- Dr. S. Papanicolopulos & Prof. J. Y. Ooi

- TIMELINE

- 2014 - 2018

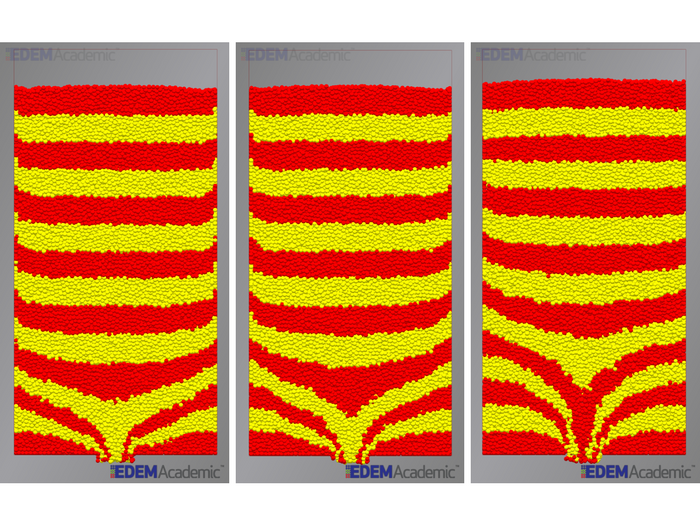

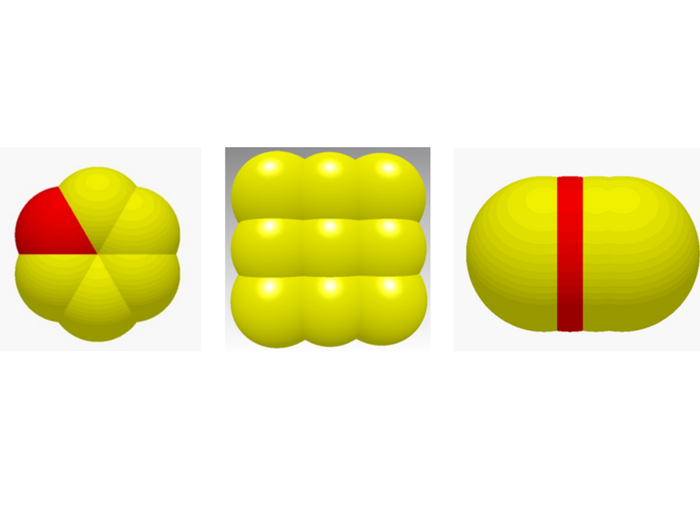

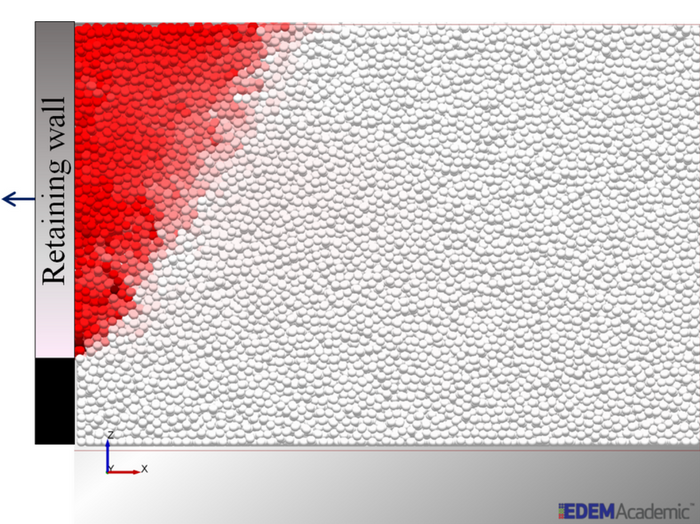

The majority of particle-scale studies using the Discrete Element Method (DEM) assume the particles to be perfect spheres. Despite this widely used assumption, it has been observed that the particle shape and the resulting geometric interlocking between particles is a primary contributor to the overall shearing resistance and is therefore critical for predicting the behavior of a granular assembly. In this respect, my project uses EDEM to evaluate the shearing and flowing characteristics of particles when using two popular shape representation methods: constraining the rotational freedom of the spheres using a rolling friction model, and using a multi-spheres approach. Considering a flat-bottom silo, the influence of two rolling friction models on packing and discharge of spherical particles has been investigated (e.g. see Fig. 1). It is clear that the flow kinematics are highly influenced by the incorporation of the rolling resistance models. Moreover, the shearing characteristics of the multi-spherical particles have been assessed through conducting Jenike shear tests (Soltanbeigi et al. 2017). Various shapes have been considered to characterize the effect of particle surface bumpiness on the bulk response of multi-sphere particles (examples are shown in Fig. 2). EDEM has enabled the observation of the contacts evolutions and the dilation of the particles during the shearing (see the video, the vertical dislocation of the upper ring is a result of dilatancy in the sample). Additionally, a side study has been conducted to observe the influence of particle shape on the failure mechanism of a cohesionless backfill (Soltanbeigi et al. 2016), see Fig 3. Results confirmed the capability of DEM in prediction of the failure mechanism at active states. Furthermore, the dependency of the failure surface geometry on the particle shape characteristics has been observed. SPONSOR FP7 Marie Curie Actions (T-MAPPP) RESULTS B. Soltanbeigi, S.A. Papanicolopulos and J.Y. Ooi, "Particle shape effect on deformation localization during quasi-static flow at active state", 5th International Conference on Geotechnical Engineering and Soil Mechanics, Tehran, IRAN (2016). B. Soltanbeigi, A. Podlozhnyuk, J. Y. Ooi, C. Kloss and S.-A. Papanicolopulos, "Comparison of multi-sphere and superquadric particle representation for modeling shearing and flow characteristics of granular assemblies", Powders and Grains, Montpellier, France (2017).

Fig. 1. The discharge of spherical particles from a flat bottom silo in the absence/presence of the rolling friction, from left to right: no rolling resistance, RVD rolling friction model with µr=0.1, default rolling friction model in EDEM with µr=0.1

Fig. 2. Examples of the considered shapes in evaluating the shearing response of multi-spheres

Fig. 3. Investigating the failure mechanism for a cohesionless backfill during active state (colored by magnitude of velocity)

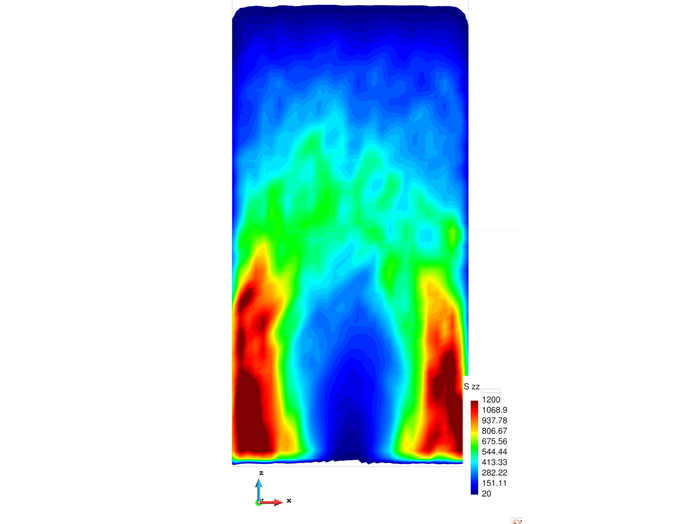

Fig. 4. Vertical stress distribution inside a flat bottom silo (DEM data are averaged over both spatial and temporal scales)

Video of Jenike shear tester set-up (visualization of the contact network for cubical shape particles)

EDEM facilitated my entrance to the DEM world with its easy-to-use framework. Everything you create, such as geometries, particles and factories, can be visualized immediately. Moreover, it gives you the ability of real-time observation throughout the simulation process, which is definitely a useful option. Additionally, I find the API and coupling capabilities of EDEM outstanding, which helped me to simulate stress-controlled shearing tests. Moreover, EDEM has recently enhanced the process of transforming the DEM data to Particle Analytics software (P4), which enables the coarse-graining of the results