- RESEARCHER

- Jiawei Xu

- INSTITUTE

- Zhejiang University, China

- DEPARTMENT

- Department of Civil Engineering

- SUPERVISOR

- Prof. Xuecheng Bian & Prof. Jin Ooi

- TIMELINE

- 03/2015 - 02/2018

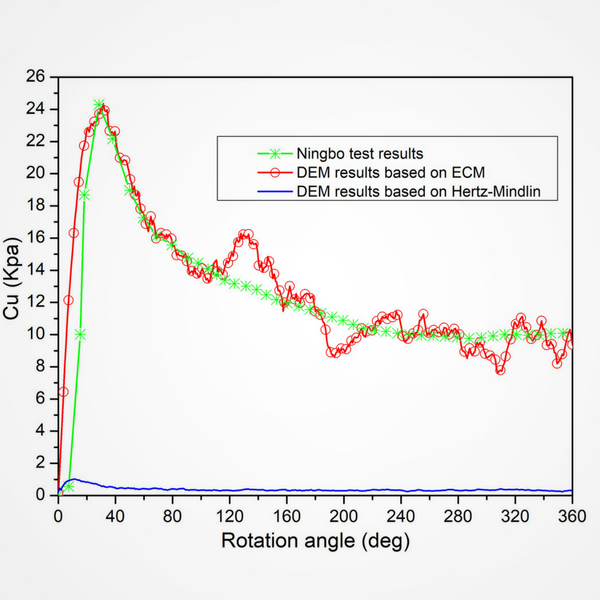

In the southeast area of China, infrastructures like railway or metro are built on the soft soil which has characteristics of high water content and low shear strength. The inner mechanism of soft soil when faced with disturbance or excavation remains to be solved, many researchers use the Finite Element Method (FEM) to simulate the process of laboratory experiment or the engineering project like excavation under tunnel boring machine and the vibration of embankment under cyclic loading caused by high speed railway. Due to the discrete nature of soft soil, it is hard to figure out the inner mechanism of soft soil during deformation. So, we try to solve the problem by using the Discrete Element Method (DEM) and for the characteristics of soft soil, we used the Edinburgh cohesive model to simulate the interaction between particles. We have successfully verified the discrete element method connected with the Edinburgh cohesive contact model can capture the macro behavior of soft clay during compressing or shearing. We have conducted many field tests like CPT test, shear vane test and laboratory tests like triaxial test and consolidation test, then we built the DEM model in EDEM like confined and unconfined compression model, shear vane test model. Comparing the results between experiments and numerical model, we got the similar results, then we analyzed the result on particle level to find the inner mechanism  Fig. 1. Comparsion of field-test and DEM simulation results

Fig. 1. Comparsion of field-test and DEM simulation results

Fig. 2. DEM simulation of shearing process

Fig. 3. Animation of shearing process view in -z direction (particles colored by velocity)

Fig. 4. Animation of shearing process view in -x direction (particles colored by velocity)

Fig. 5. DEM simulation of shearing process

EDEM software has a very user-friendly interface for pre or post-processing - it is very convenient for us to build a numerical model and analyze the results. The format of exported results from EDEM can be used in many post-processing software such as MATLAB. I really appreciate that EDEM software can support our academic research.