- RESEARCHER

- Robert Krol

- INSTITUTE

- Wroclaw University of Science & Technology, Poland

- DEPARTMENT

- Faculty of Geoengineering, Mining & Geology

- TIMELINE

- Ongoing

Identification of the stream of transported mine output has a great importance for the effectiveness of ore processing and for the control of mining operations. The flow of mine ore is modeled with the use of simulation methods, whose reliability largely depend on how accurately a particular transportation system and its operation are reproduced in the model. Particular attention must be paid to accurate modeling of ore behavior in the nodes of the transportation system, i.e. in the bunkers. Bunkers effect the averaging of ore parameters, as the portions of mined material subsequently added to the bunker change their position and mix. Modeling the behavior of mined ore inside the bunker is the object of tests performed with the use of DEM. The project is focused on parameterizing the mined ore data (granulation, ore stream efficiency) and the bunker data (geometry, discharge technology), which are required to build a DEM model of an ore bunker following the design of an actual large-capacity shaft station bunker located in an underground copper ore mine. SPONSOR Framework Programme for the Research and Innovation Horizon 2020 Publications "˜Walker P., Kawalec W., Krà³l R. (2019) Application of the Discrete Element Method (DEM) for Simulation of the Ore Flow Inside the Shaft Ore Bunker in the Underground Copper Ore Mine. In: Burduk A., Chlebus E., Nowakowski T., Tubis A. (eds) Intelligent Systems in Production Engineering and Maintenance. ISPEM 2018. Advances in Intelligent Systems and Computing', vol 835. Springer, Cham; DOI

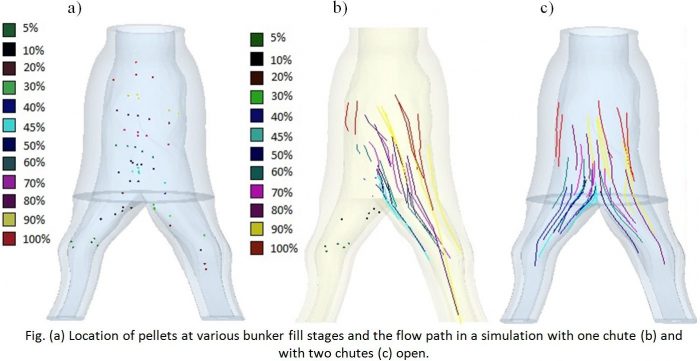

Fig 1. Location of pellets at various bunker fill stages and the flow path in a simulation with one chute (b) and with two chutes (c) open

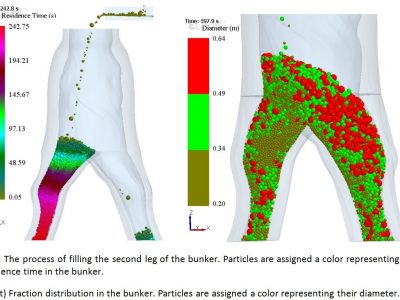

Fig 2. The process of filling the second leg of the bunker and fraction distribution in the bunker

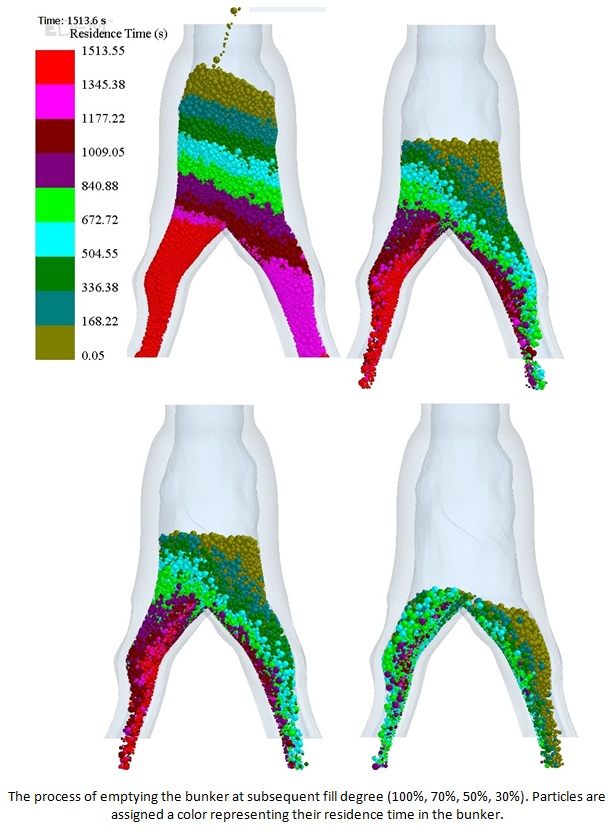

Fig 3. The process of emptying the bunker at subsequent fill degrees.

The research on modelling the ore flow through the complex belt conveyor transportation system (with bunkers) is still under development. Some other papers have been submitted and soon will be published.