Hello,

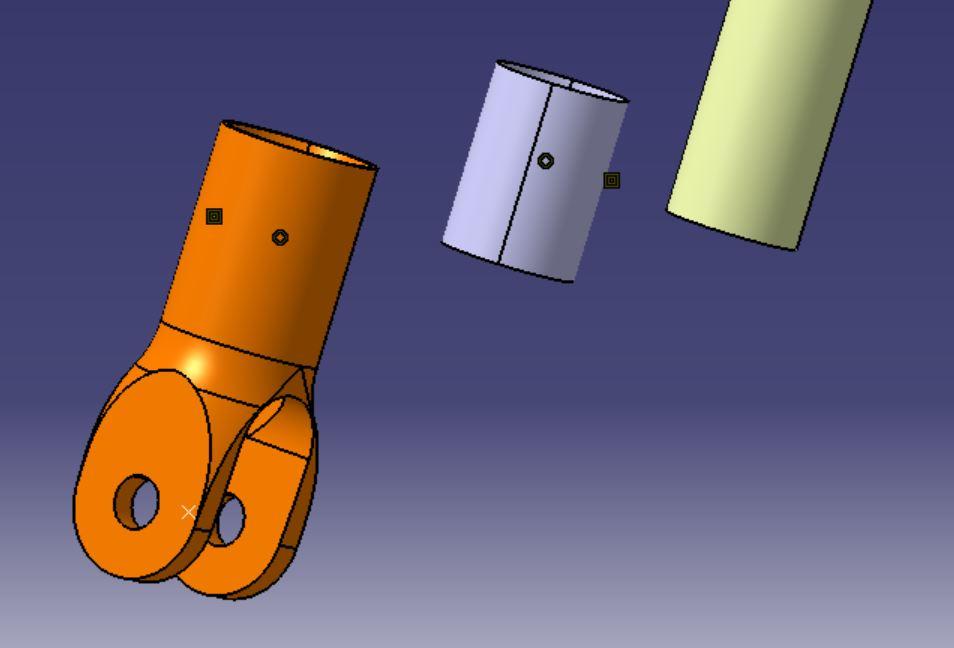

I would like to perform a linear static analysis(stiffness) of a composite wishbone (2D Shell). The forkends and brackets are Aluminium (3D-Solid). The solid elements are glued to the 2d element. For the glue, i made a solid component and imported the assebmly from CATIA (Material information of the glue is available). 1.How can I create the contacts between the parts? 2.Is there a special case between 2d and 3d elements to create a contact 3.Is 'TIE' the right contact method? I have got another question regarding diffrent subject: 4. Is there any possibility to change the coordinate system of my assembly in Hypermesh (optistruct)? Thanks in advance, best regards

<?xml version="1.0" encoding="UTF-8"?>