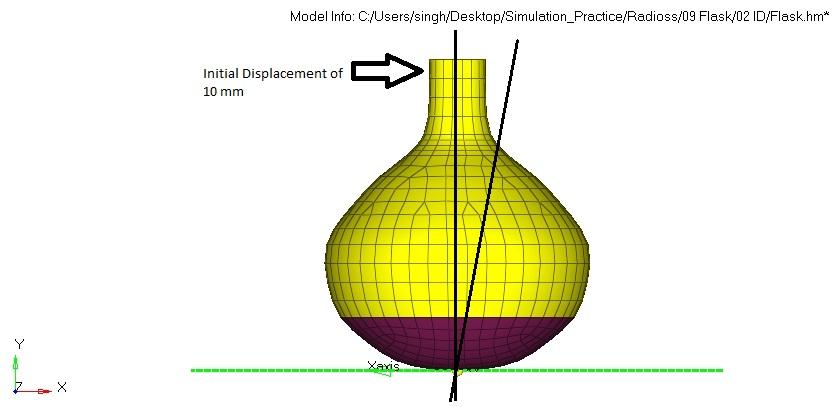

For shake of knowledge i tried to feed initial displacement for 10ms as imposed dis placement (T= 0, 0 Disp= 0,10). As below in given image.

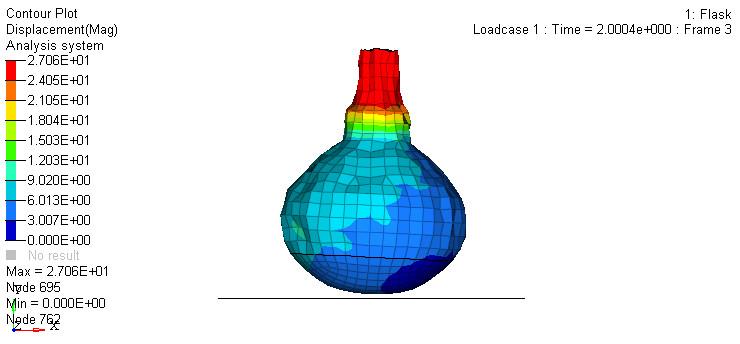

What i expect - flask should oscillate about center axis. But in results what i found there is huge vibration in flask as shown in figure

Later on i tried with initial velocity (1cm/sec) also. but same happened.

Can anyone explained why it happened ?

here my unit assumption in (mm,kg,ms). Related .rad file and .h3d files are attached.

Unable to find an attachment - read this blog