Hi,

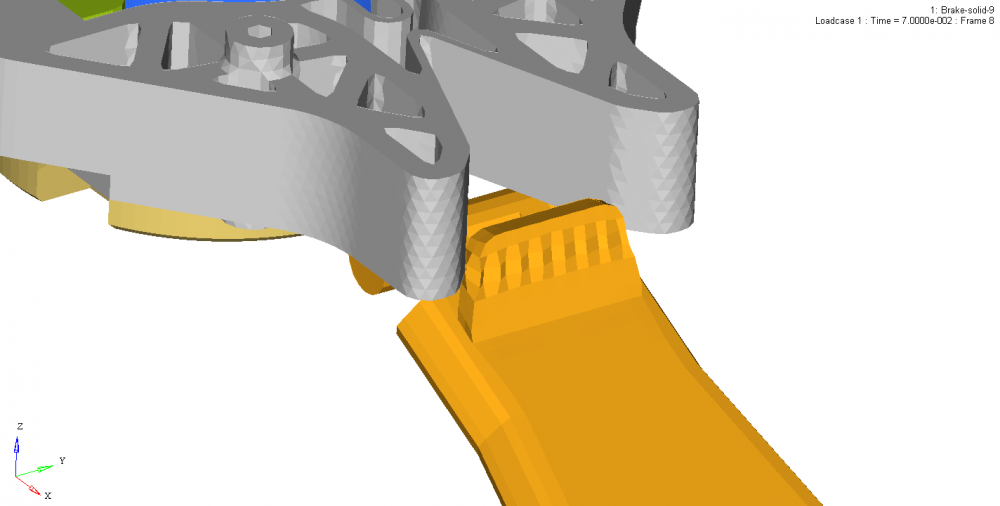

I am trying a brake problem in Radioss.

Both type7 and 11 interface are used with Istf=4, Igap=2, Intatct=6, Iform=2 , No intersections/ penetration in the model and out file.

Please have a look at the animation and out file, let me know whats might be the reason for element distortion.

<?xml version="1.0" encoding="UTF-8"?>

Unable to find an attachment - read this blog