Dear all,

I would like to implement a macro for the separate calculation of the different torque components (cogging torque, reluctance torque and interaction torque) in 3D simulation of motors using the Frozen Permeability Method. I already derived the Frozen Permeability method for the 3D case from the existing 2D macro.

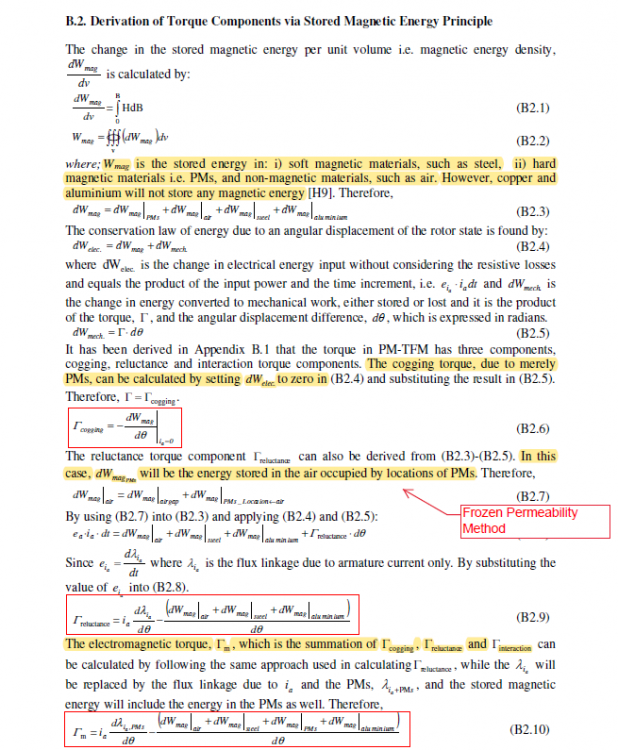

I found a suitable method in Baserrah, S. Theoretical and Experimental Investigations of a Permanent Magnet Excited Transverse Flux Machine with a Segmented Stator for In-Wheel Motor Applications. Dissertation, Universität Bremen, Bremen, 2014. (page 238).

<?xml version="1.0" encoding="UTF-8"?>

In the first step I would like to calculate the cogging torque using the stored magnetic energy (the Frozen Permeability Method is not yet required for this).

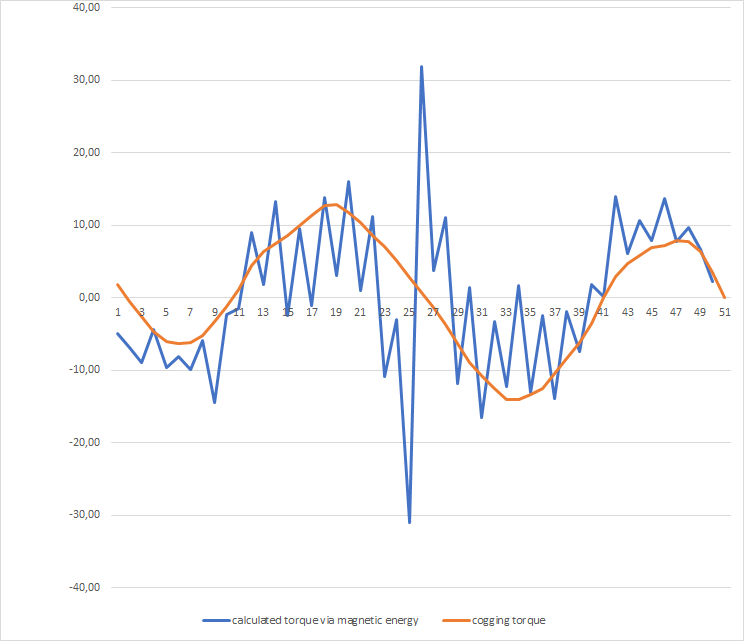

With the help of a sensor I can determine the stored magnetic energy. Since I take advantage of the symmetry and periodicity of the motor and simulate only a part of it, I have to multiply the result by a factor. The derivation according to the rotor angle roughly gives the course of the cogging torque, but with strong fluctuations compared to the calculation via 'TorqueElecMag(ROTOR)' (see image below).

Does anyone have any idea what may be the cause of this deviation? I have concerns about using this procedure to calculate the reluctance torque, because large deviations are also to be expected here. Can anyone give me a hint on how to extract the reluctance torque from the simulation?

Many thanks in advance!

Mandy