Hi all,

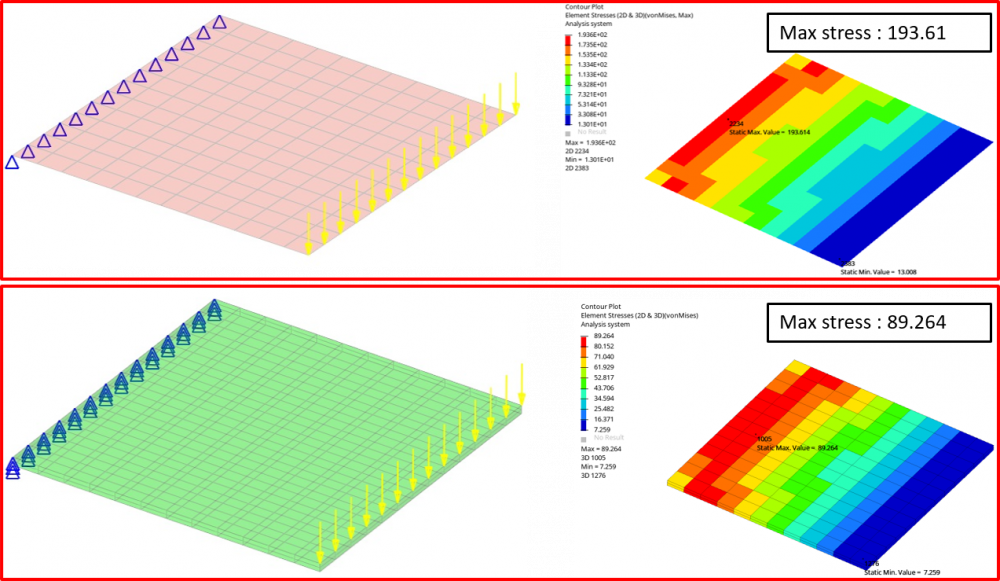

I had modeled a steel Plates of two Cases of Same config as shown in fig.

Case :1 2D PLATE 2mm Thickness, F=140N(10N/14 Nodes), constraints at opposite end.

Case :2 3D hex Plate 2mm Thickness with 2 Layer of Mesh, F=140N(10N/14 Nodes), constraints at opposite end.

Clarification required :

1. Both plates are same in Boundary conditions , dimensions and material property. only the element type varies but why the stress induced is different ?

<?xml version="1.0" encoding="UTF-8"?>