Hi all,

I am having difficulty with results interpretation when I do a tank slosh analysis. I have uploaded my files for reference. I wanted to upload the results, but they exceed the limit for size. I have pictures for reference.

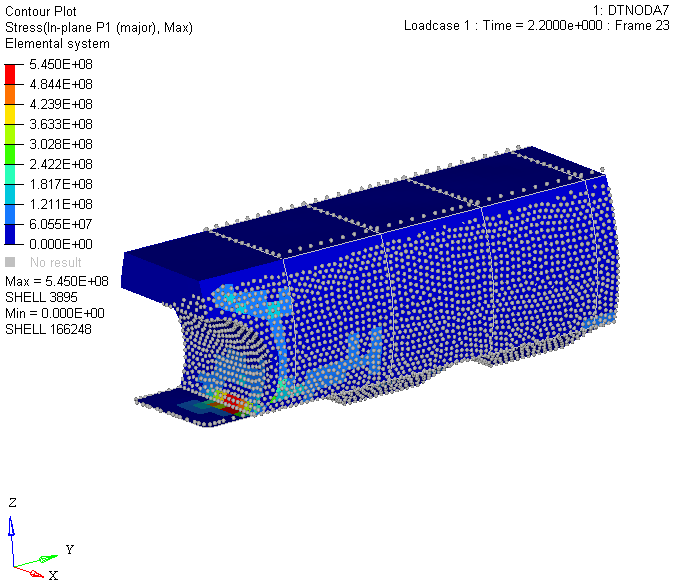

In the model, I have SPH particles slamming into the sidewalls of a tank, however as you can see, there is hardly any stress in the walls. This makes no sense, and is leading me to believe there is a high rigidity from something I have done, but I just can't seem to pinpoint it. I tried running the simulation without beams, and even then, it was still very rigid, so I do not think it is a material or property issue. I also ran it with triple the initial acceleration, to almost no effect.

For symmetry, I created a wall dividing the tank in half, with very low density and yongs modulus, as I just wanted it to prevent SPH particles from flowing out, without actually changing the physics. The edges of the tank at the symmetry have the BC in the 246 directions, and should not be preventing any motion parallel to the symmetry plane.

If anyone has any ideas, please let me know.

Thanks in advance.

Unable to find an attachment - read this blog