Dear all

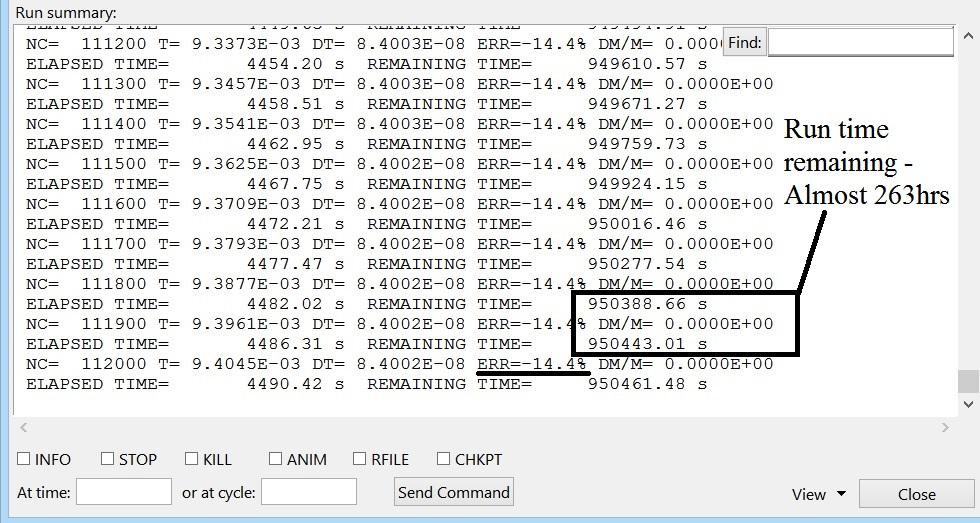

I need a help regarding understanding the HyperWorks Solver summery for RADIOSS. I am new to this software and does not have good amount of knowledge, and am trying to solve an Explicit analysis problem. While giving all the necessary inputs in Radioss for a model, I am trying to run the solution. I had tried to run the solver 2 times previously for 10 hrs but couldn't understand how long should I keep waiting. While reading the solver summery, I had seen that it shows 'Remaining Time as 950000 Sec'. Which means it might take 263 hrs (about 10 days) to get the solution done by the HyperWorks solver. Is this a normal TIME which Radioss takes to solve some problems? Whenever I try to do some other work in my laptop, the solver time increases rapidly. At about 'Remaining time 90000 s' the solver works very slow.

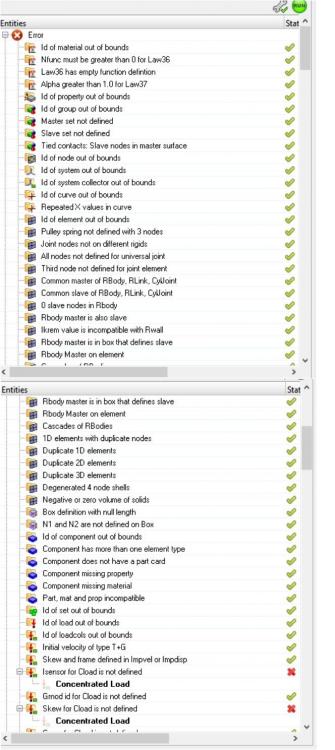

My model is a mechanical component, with approximately 30000 elements, used type7 contact at 4 locations. I tried to check it through Model Checker and found almost all parameters getting passed through the check except two errors - 'lsensor for Cload not defined' and 'Skew for Cload not defined' . The image can be seen in the attachment for the detail. While running through solver, I can see '0 Error and 5 Warnings'.

Can any one advice me on urgent basis about 2 of my queries:'

1. Am I doing some mistake because of which such a long expected time is showing to complete the solution? Is there any thing which I can do to solve it sooner. By reading few posts of this forum, I tried to apply 'ENG_DT_INTER/del' option to avoid possible divergence.

2. My error % initially increased to 24% than came down to 14% when I previously run my solver for the same problem for 10 hrs. Does this Error % shows that I had done some mistake? or is it fine to vary it so much? Is there any limit for Error % which I should consider?

Regards

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>