Hi

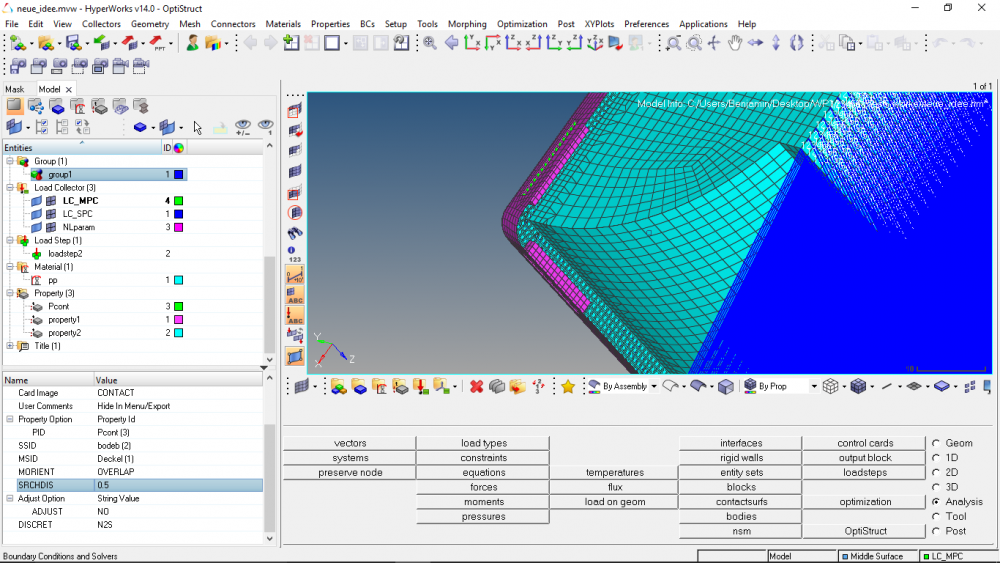

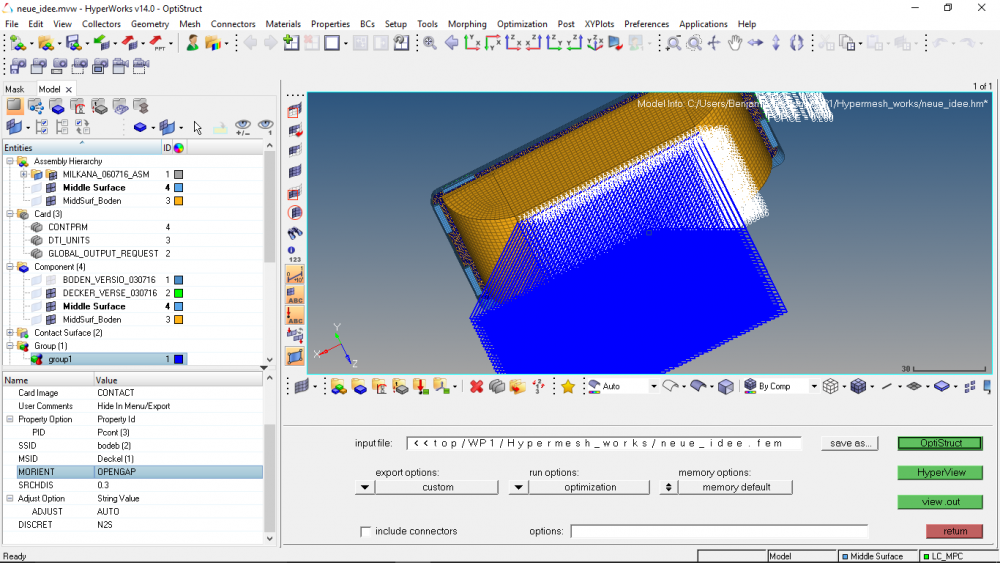

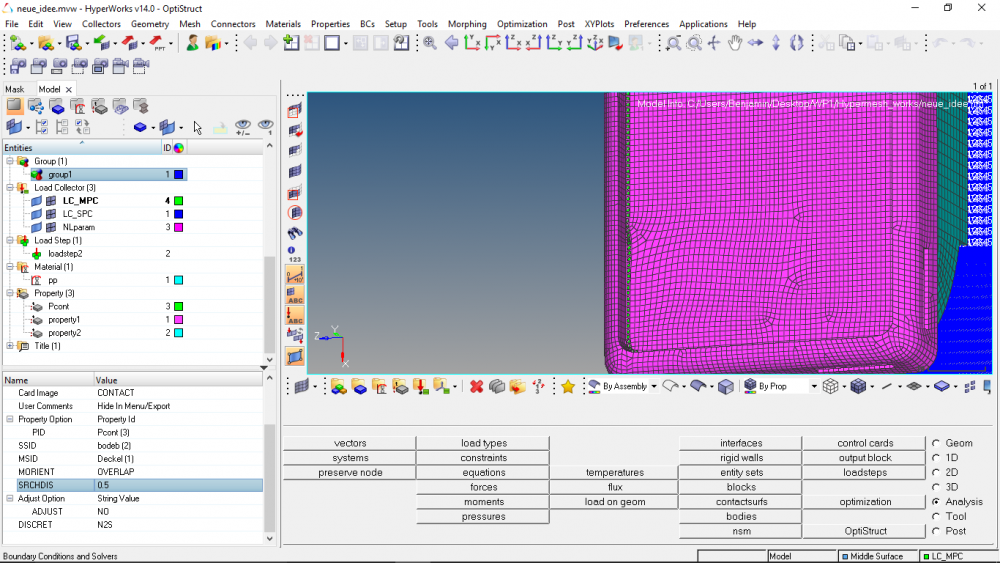

i'm trying to simulate an packaging consiting of two parts, the bottom and the cover. The cover is fixed with one plane on the upper side of a lipsurface on the top of the bottom an on the buttomside of the lipsurface. (See figute below) . The aim is to look when the cover ist detaching from the rest.

My problem is i don`t know how two simulat that problem. every time i am running the imulation there is no convergence

I created the cover and the bottom and also the contac surfaces and interface with overlap.

After i Created the pcont card, material, conprm, constrains, an the NLParam and forces

THe LoadCase is non linear static analyse.

The problem is there are no results running that simulation.

can you tell me where is my problem?

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>