Good afternoon,

I often find out that contatct type 7 drives the simulation to error due to negative or null time step.

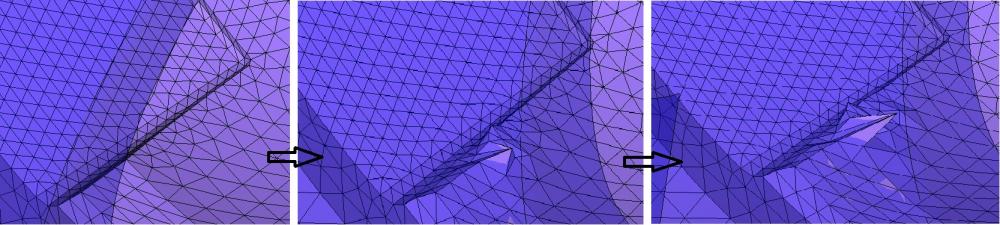

Attached to this message there's a picture that shows what usually happend in this case: there's a rounded surface that grawls over an edge surface, the consequence is that the master surface grabs a node from the slave surface (or vice-versa) causing an eccessive deformation of an element of the mesh, so the time step becomes very small.

I'm I doing something wrong? Is there a way to improve the contact characteristics to avoid time step decrease?

Thanks for helping me

<?xml version="1.0" encoding="UTF-8"?>