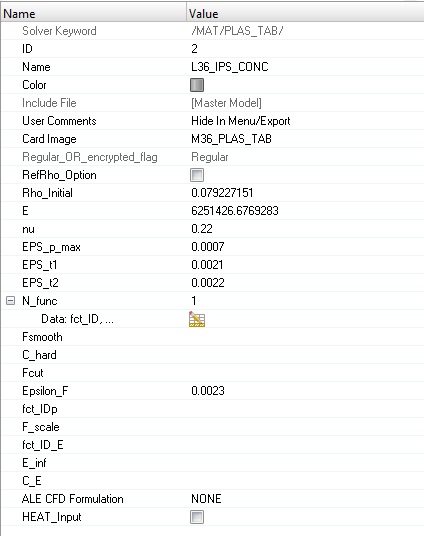

I am trying to understand the various parameters for LAW36.

1. EPS_p_max

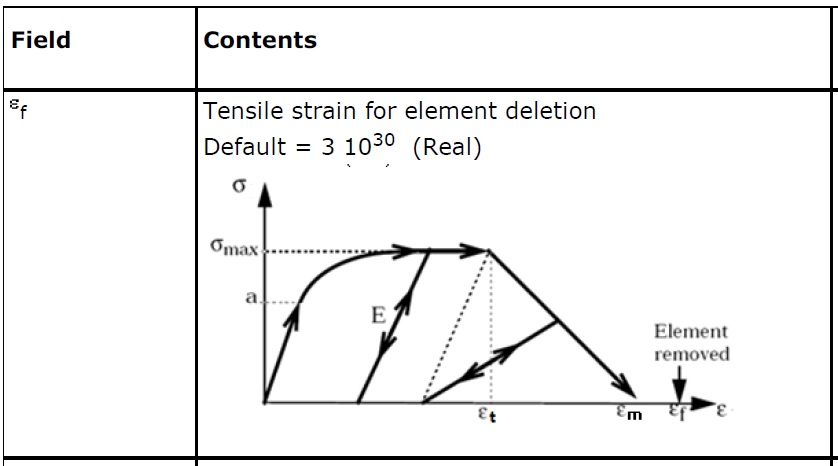

2. EPS_t1 - Maximum tensile failure strain (EPSt in reference guide)

3. EPS_t2 - Maximum tensile failure damage (EPSm in reference guide)

4. Epsilon_F - Tensile strain for element deletion (EPSf in reference guide)

What I understand about these is :

1. EPS_p_max - Plastic Strain beyond this will cause element deletion

2. EPS_t1 - Strain beyond which the line connecting t1 and t2 will be used

3. EPS_t2 - Strain beyond which the element will be separated from the connected elements

4. Epsilon_F - Strain beyond which element will be deleted

If my understanding is correct then what is the point of having Epsilon_F? We already have EPS_p_max to determine the element deletion strain.

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>