hi

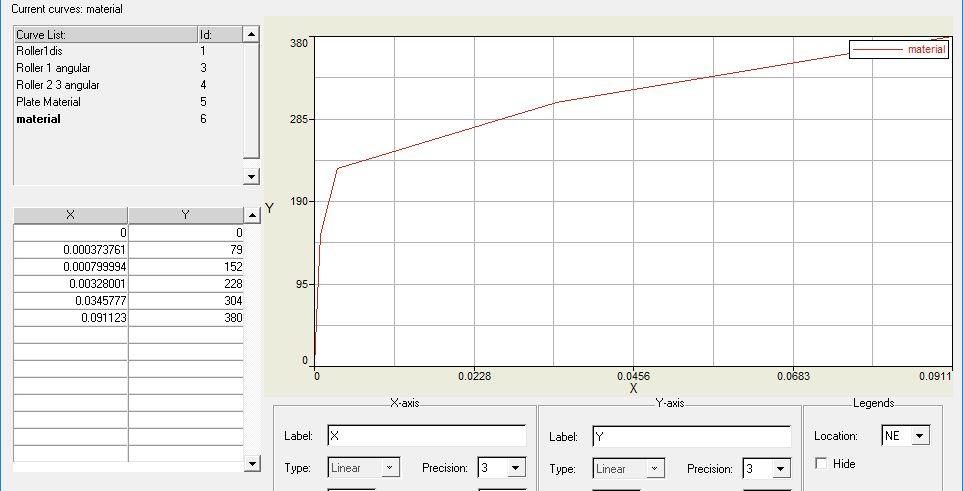

i am doing simulation on 3 point roll bending in radioss solver

first step i applied displacement to the top roller in z direction then i applied peripheral velocity to 3 rolls then i stopped the velocity again applied top roller displacement and given velocity of the roll in different direction.

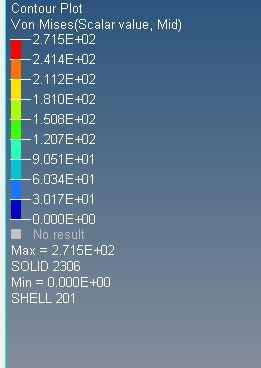

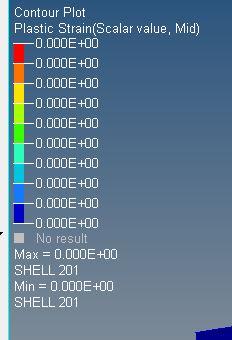

i am not getting the plastic strain value while the stress i am getting larger than then the yield value