Dear all,

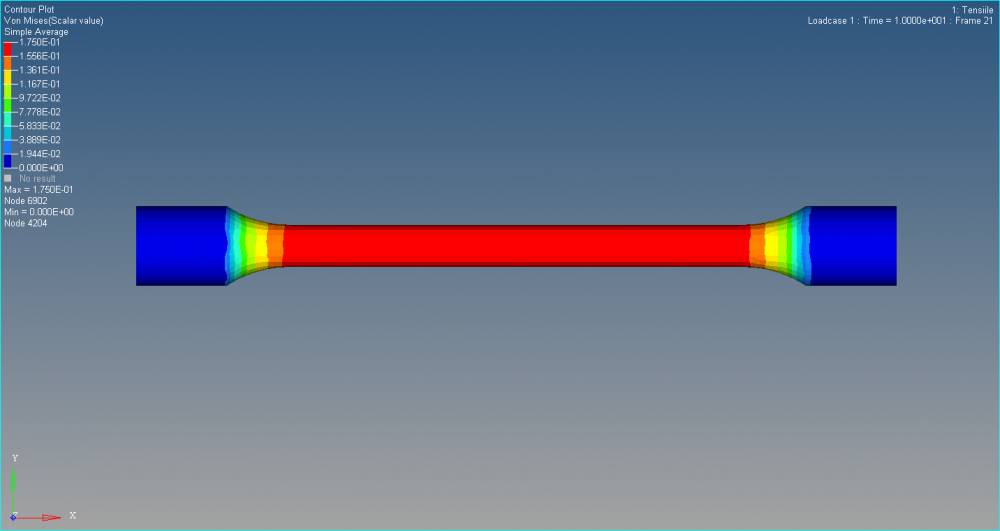

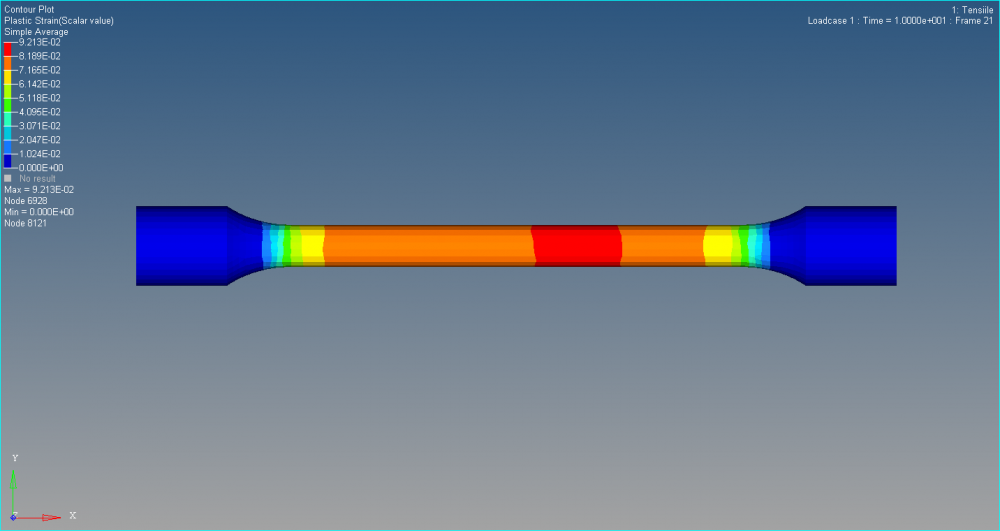

I've done with tutorial RD-3500 about tensile test & the result shows that the part is broken. And then I try to make 3D model of it problem and I use MAT23 & P14_Solid to the simulation.

The problem is, when I open the result in hyperview, my 3D model is not broken at ALL (see the attachment). What's wrong with my model?

Please help me. Thank you

Best regards,

Iron_Man

Note : If you need the .HM file, please message me.

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>