Structural Steel Connections often require carefully designed components to safely transfer loads to the ground. In this challenge we will design a 3D Printed Structural Steel Connector to transfer loads between a set of structural steel members to the ground. The design must be such that it can accommodate bolted or welded connections to connect to the Structural Steel Components, and the goal of the design is to minimize weight while ensuring the load transfer to the ground occurs without plastic deformation. The attached STMOD file can be a starting point. It contains a sample design space, loads, and supports. Feel free to adjust the design space, and optimization settings (lattice optimization) to your preferences.

Level: Medium

Product Required: Inspire

The solution can be attached in the comment section of this post. The desired output format is a JPG or PNG showing your optimized design.

The solution to Challenge "Cycling Shoe Cleat Design" can be found Here

If you would like to solve more challenges and get regular challenge release updates, Subscribe to the Altair Community Challenge forum

Responses from community:

Karli:

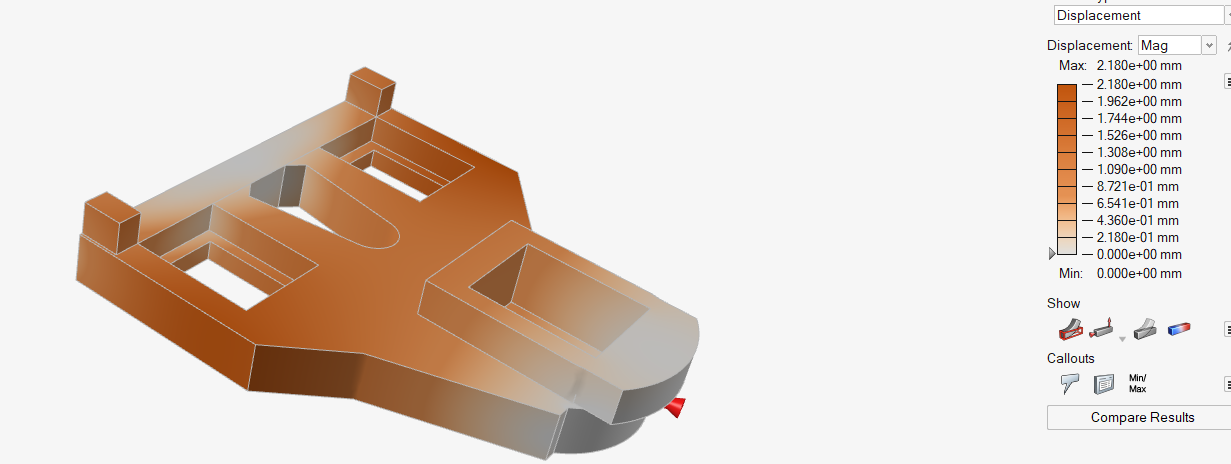

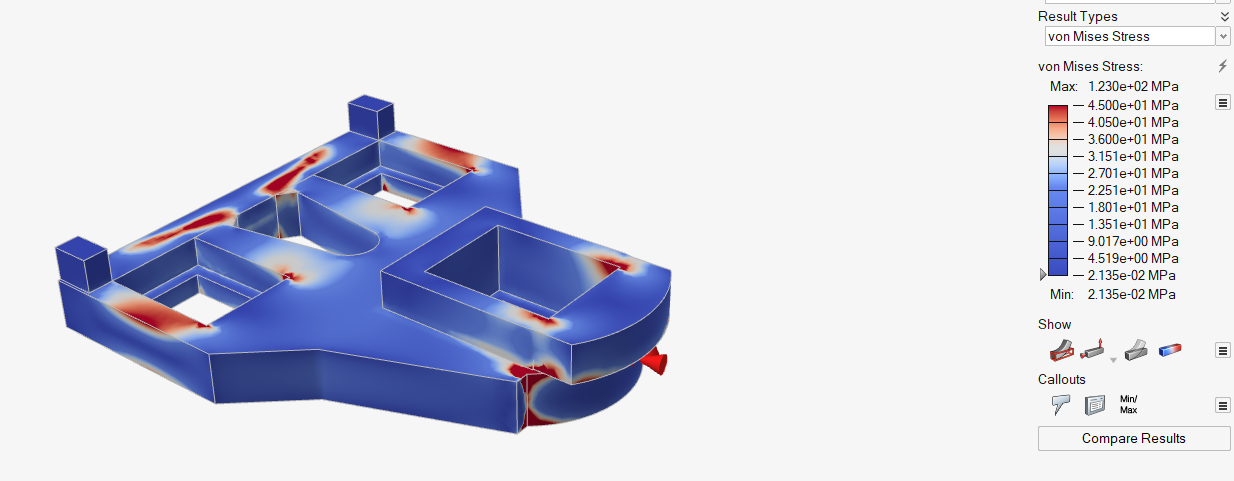

So I run some tests to optimize the structure, but it was not so easy to take something away. From the start model, it already bends 1,6 mm and von mises goes over abs limit (105 MPa). There was no mention about changing the material, so I stuck with abs.

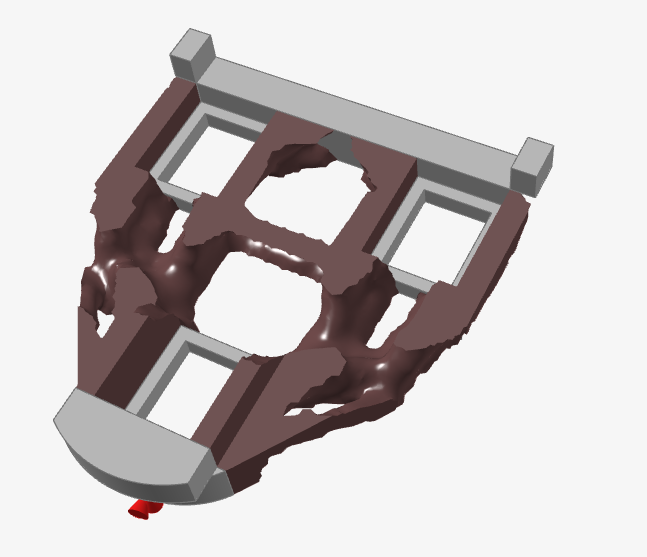

Here is my optimize result:

So this is my result:

I got max displacment 2,18 mm and max von mises 123 MPa. The weight is now 21 g

Sourav Das:

Kunal Pandit:

Structural steel connections play a critical role in bearing and transferring substantial loads between beams and columns. Therefore, in the process of optimization, it is imperative to execute meticulous material removal to ensure that stress and displacement remain within acceptable limits.

The original values for mass, stress, and displacement were as follows: 1108.807 kg, 14.74 MPa, and 0.7679 mm, respectively.

It is worth noting that the connections offer flexibility in terms of assembly methods, including spot welds, line welds, or bolts. In this specific task, spot welds were employed, resulting in a total mass of 511.109 kilograms.

For the structural analysis performed after optimization, spot welds were not utilized due to constraints within Optistruct, making it necessary to exclude them from the analysis.