A dump truck is used for transporting materials such as gravel, coal, rock, dirt, etc. A typical dump truck consists of an open bed connected to the rear end of the cabin. The truck body is equipped with hydraulic rams to unload the material.

Dum trucks need to load and unload material quickly and without spillage to help with productivity. Any material remaining after unloading negatively impacts the truck fuel efficiency as this material has to then be carried around for the next cycle. Faster unloading also improves the overall efficiency of the process.

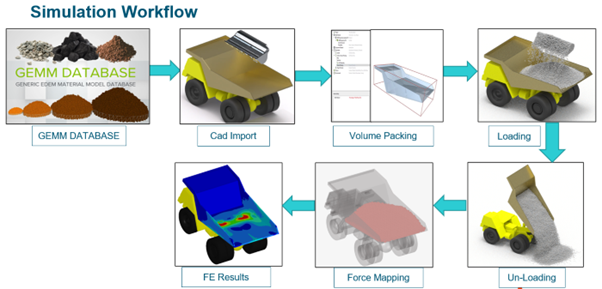

This example outlines how to analyze the structural strength of a dump truck body during loading and unloading. Files used in this example can be downloaded here:

Tools used in this example:

Altair tools can be used to:

- Understand how different materials affect designs

- Virtually test designs for a wide range of materials with different properties

- Predict bulk material behavior such as identify risk of blockages, spillage, and wear

- Analyze the loading and discharging of truck bodies

- Identify wear zones or regions of material hang-up

- Perform repetitive tests under the same conditions quickly

- Get key insight into equipment-material interactions

- Shorten design cycles

- Reduce physical prototyping and testing costs

- Increase productivity and reliability

- Design machines with greater performance

Step-1: Setup Material Model

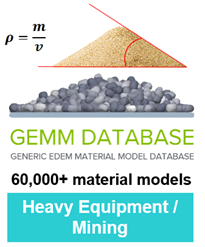

To select a Material Model either selecting a material from one of the EDEM databases or material calibration must be performed. In this example, calibration is not demonstrated, however, those who want to explore calibration please follow the below links.

In this example, the material model was chosen from the GEMM database by giving 3 simple inputs such as:

- Quantity of material to be simulated

- Bulk density

- Angle of repose

Step-2: CAD Model

EDEM supports a wide variety of CAD formats such as Catia, Solid Works, NX, and ProE and neutral files such as STEP, Parasolid, IGES etc.

Geometries are imported to EDEM via the Creator > Geometries > Import Geometry

Best Practice:

To run EDEM + FEA analysis the mesh of the part/component to which force mapping is to be carried out should be the same in both EDEM and the FEA package used (OptiStruct)

In this exercise truck body is the major focus of studying structural strength hence using Altair® Hyper Mesh® truck body is meshed and exported as a stl file.

Please refer to the below links to learn about meshing.

Step-3: Introduce Material

To create a bulk material volume packing option chosen in this example. To learn more about Factories in EDEM, watch this brief video tutorial:

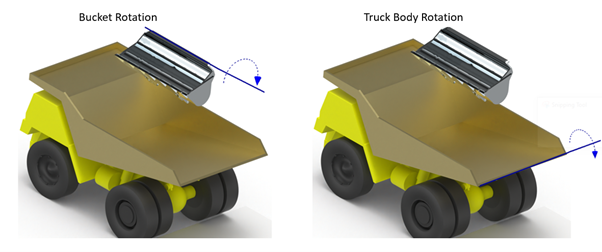

Step-4: Define Kinematics

- Assign linear rotational kinematic motion to the bucket to unload the bulk material onto the truck body

- Assign linear rotational kinematic motion to the dump truck body to unload the bulk material

Step-5: Run Simulation

- Define the time-step

- Solve loading and unloading of the bulk material

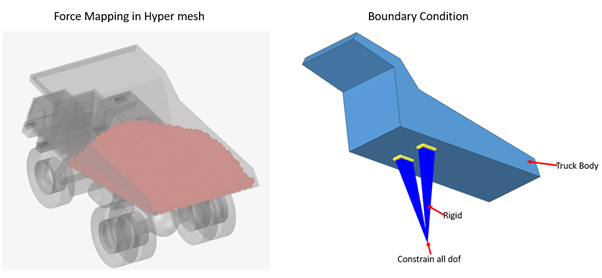

Step-6: Force Mapping and FE Simulation

- Force is exported from EDEM during loading and unloading at a specific time to understand the structural strength of the truck body.

- Please go through the link below to understand Hyper Mesh's force mapping steps.

Tutorials, How To, Troubleshooting - EDEM - HyperMesh Tutorial: Export EDEM Data for FEA Analysis of Dump Truck (altair.com)

- Define the constraints to the FE model as shown in the below picture

FEA Simulation set up reference video: Analysis Setup and Results Visualization - YouTube

- Run the Simulation using OptiStruct and Analyse the results

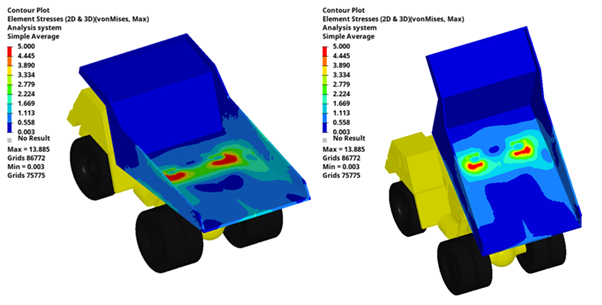

- VonMises stress of truck body during loading and unloading is shown in the below picture

Please go through the video reference of dump truck loading and unloading: DumpTruck_Loading_Unloading.mp4

For more information about EDEM for Structural analysis see: Static structural analysis for bulk solids handling applications using EDEM, OptiStruct and SimSolid

To get started with Altair EDEM please see: 4 steps to accelerate your EDEM learning curve!

Or visit the EDEM Community: Altair Community - EDEM