Hello and good afternoon,

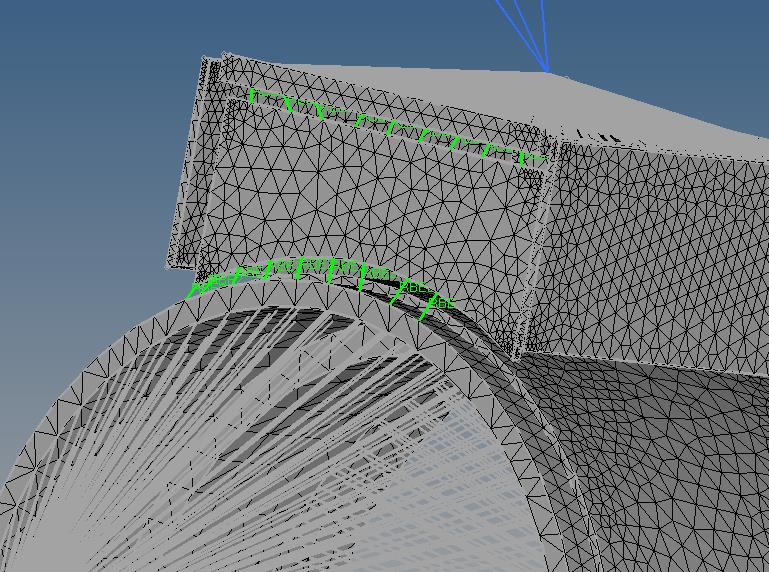

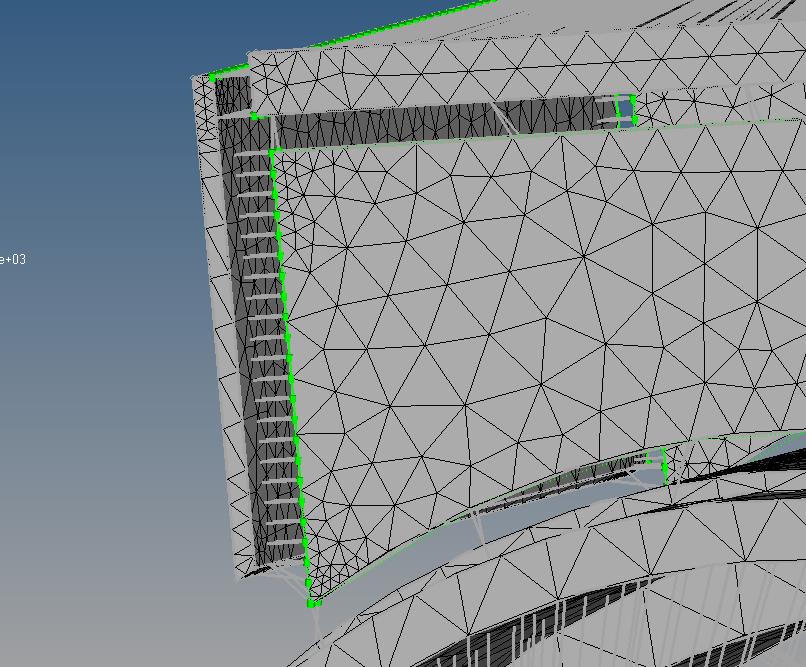

I currently have a few problems using connectors in my Hypermesh-Simulation. I am trying to connect different parts of my model together via connectors to simulate the mechanical behaviour of a welded model.

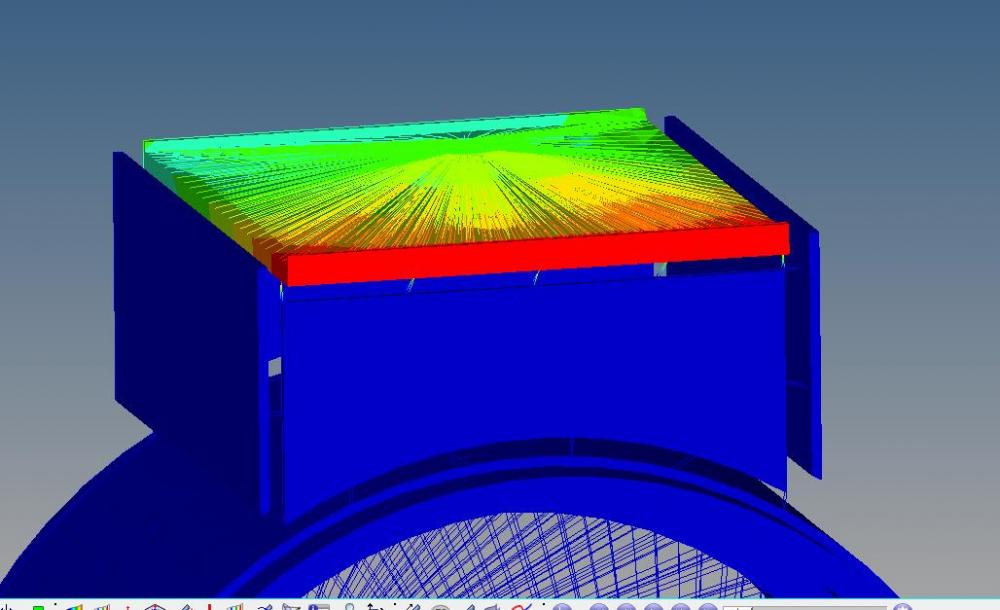

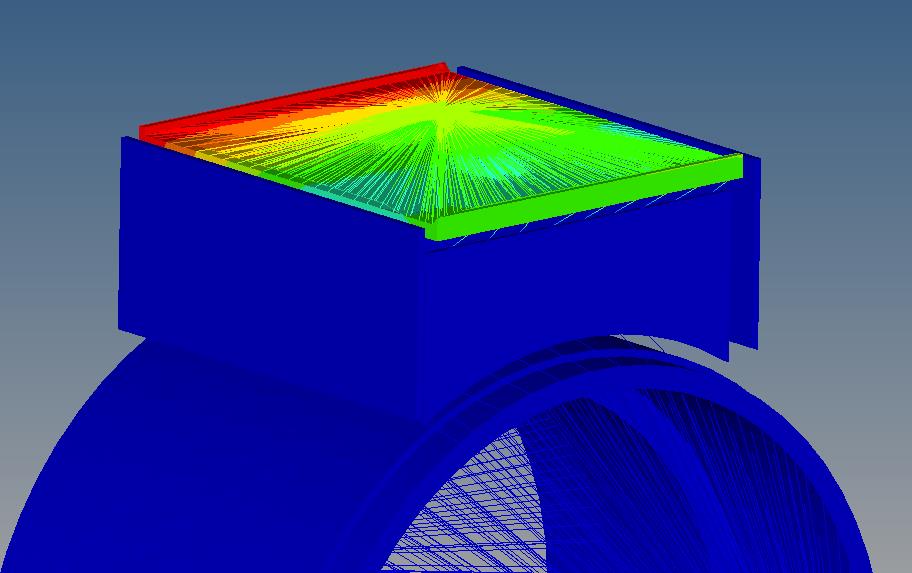

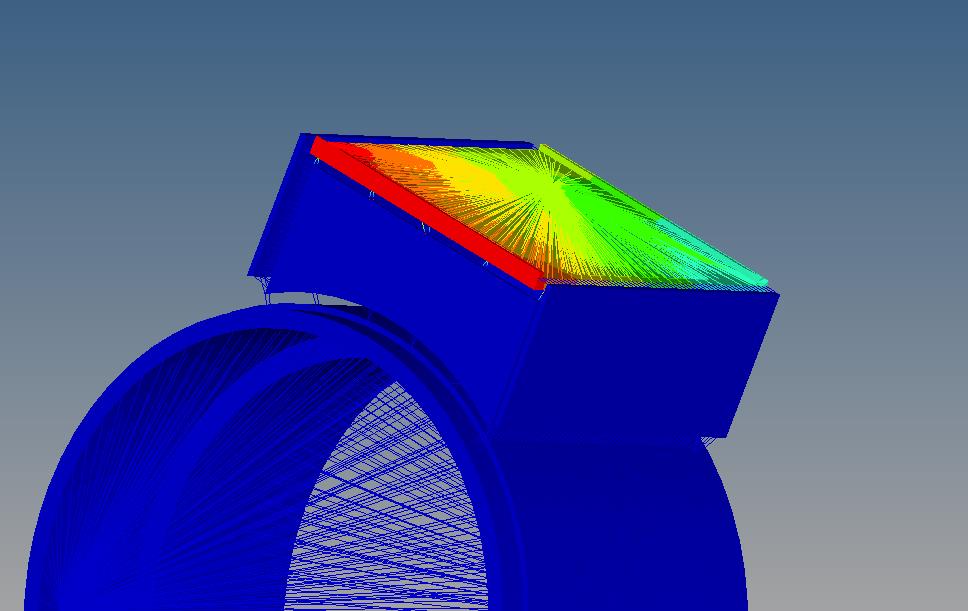

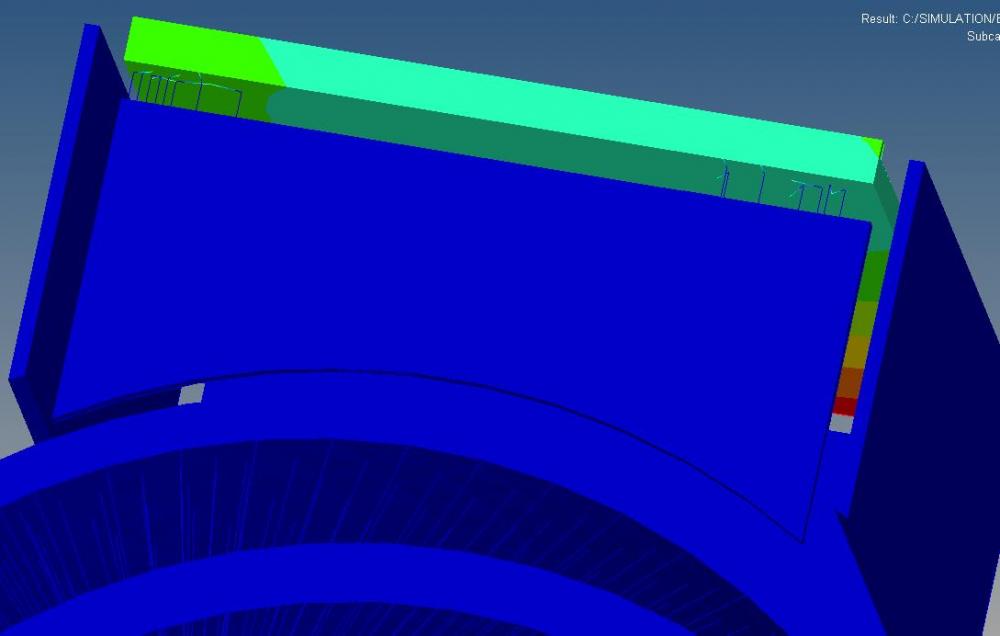

The problem with my connectors is, that they are not transferring the load into other parts of my model. I think I set them up incorrectly. Is there any kind of tutorial on how to apply connectors?

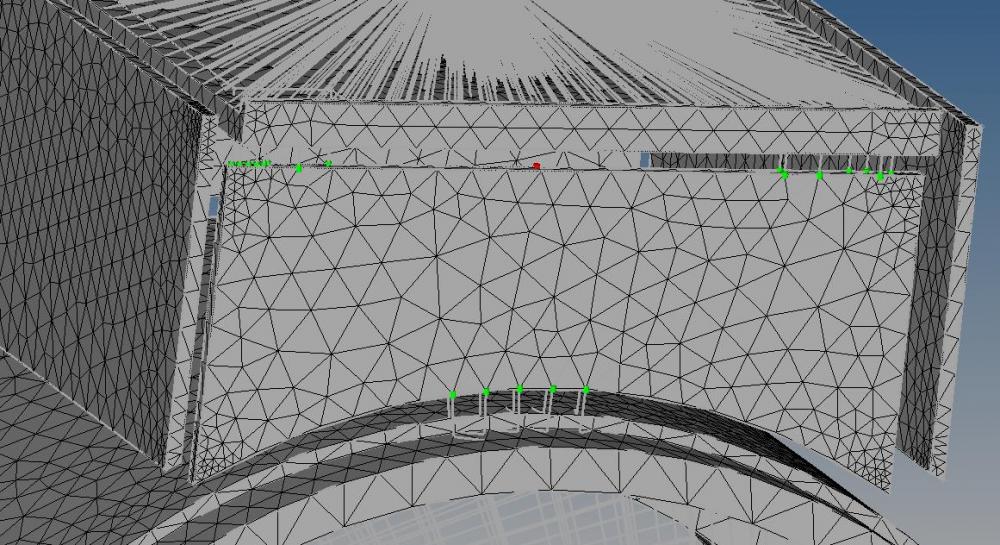

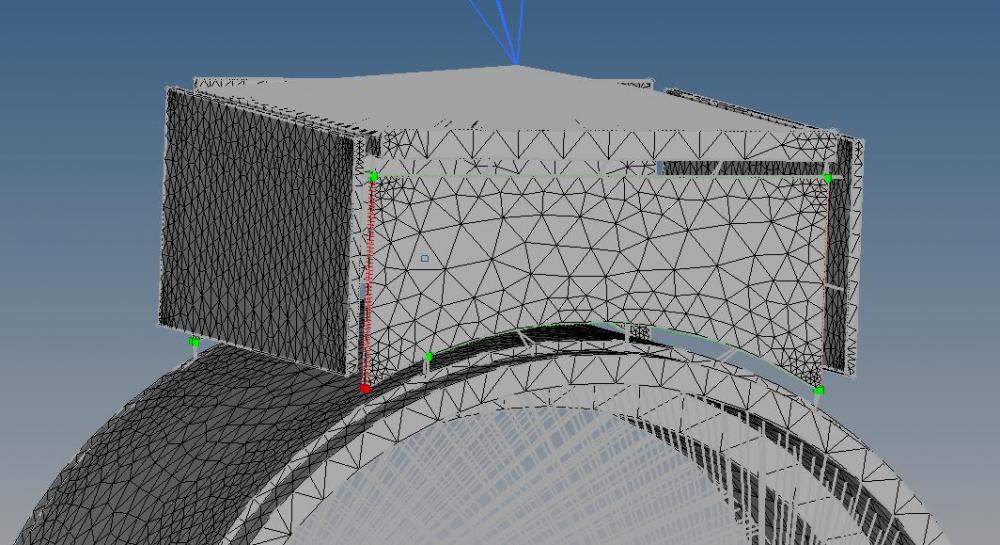

I attached a few pictures using different connectors. You will see that the parts of my model are set up with a distance of 2mm to each other. I tried using no distance first, but I could't not get the connectors to realize. Without a gap between the model parts they were always either yellow or red. Using a litte space between the parts could get the connectors to realize at least.

The only time I could get the applied loads to transfer was by using RBE2-elements and an unexploded model.

Many thanks

Steffen

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>

<?xml version="1.0" encoding="UTF-8"?>