Hi Rahul

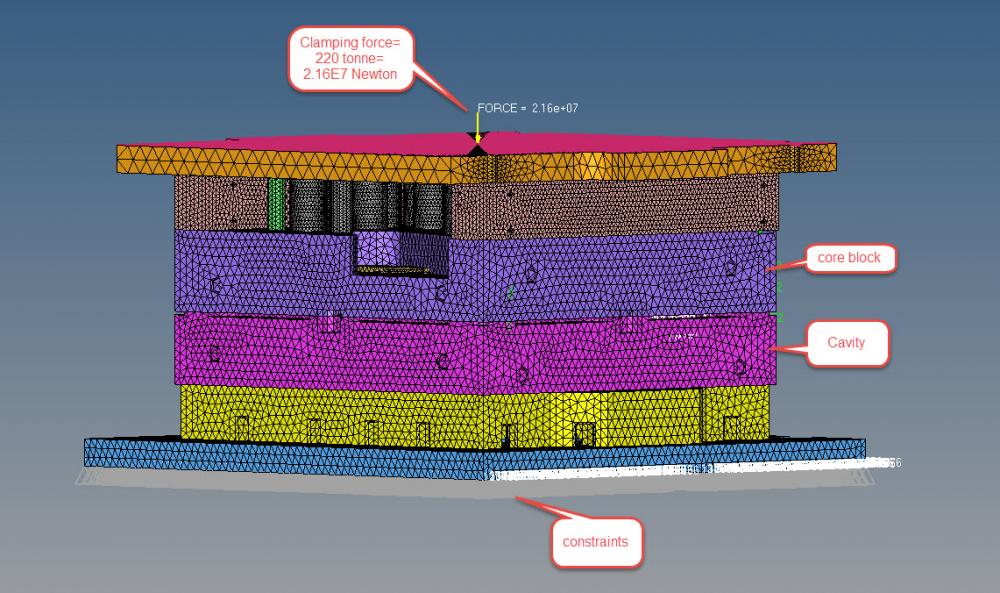

I am doing linear static analysis on a plastic injection mold assembly. Clamping force and constraints are as following

<?xml version="1.0" encoding="UTF-8"?>

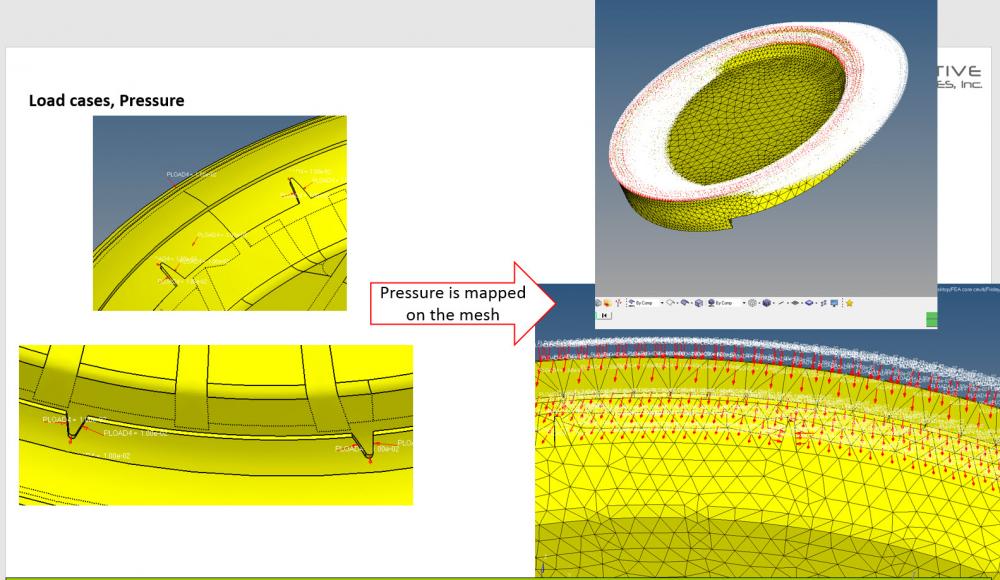

Pressure 54 MPa (This is the maximum pressure of molten plastic when it enters the cavity) is applied on core and cavity as shown below

<?xml version="1.0" encoding="UTF-8"?>

The problem is that, the maximum displacement is much more than what it should be in real case (It is almost 10 times more). I have used SI units and I checked material properties, units look right.

I don't know understand why I get this result. I have used bolt connection, RBE2 and also FREEZE contact to define connection between parts.

I sent you the model via your Dropbox link. I appreciate if you can spend some time and check my model and let me know what is the problem and why the maximum displacement I got is much more than the reality.Thanks a lot.