Shell & Solid Composite Modelling Different Behaviour

Dear Everyone,

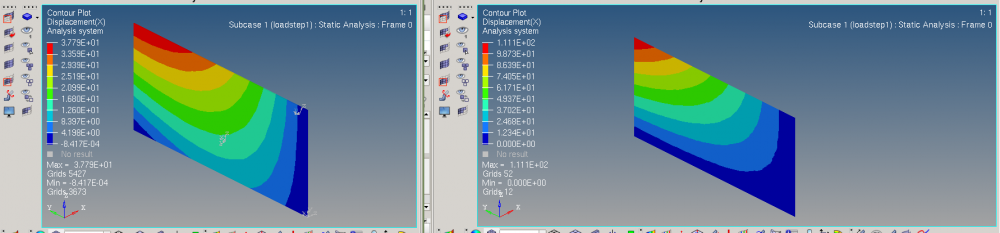

I am have been working with the shell modelling of composites, using the PCOMP-card and plies and laminate definition. I wanted to take it to the next step and try the modelling of composites using 3D elements. I have looked into the Shell to Solid Conversion of HyperMesh first and then started on my own using the PCOMPLS card. I modelled the exact same plate twice to see if I can re-do my 2D results in 3D. However I came to find that both results are vastly different.

Do you know how this could happen? Displacement of 111 vs. 37...

I have attached both of my files, could any one of you please have a quick check?

Any help would be greatly appreciated!

Best Regards,

Lennart