Topology Optimization with Changing Wall Thickness and Max Stress Considered

Hello,

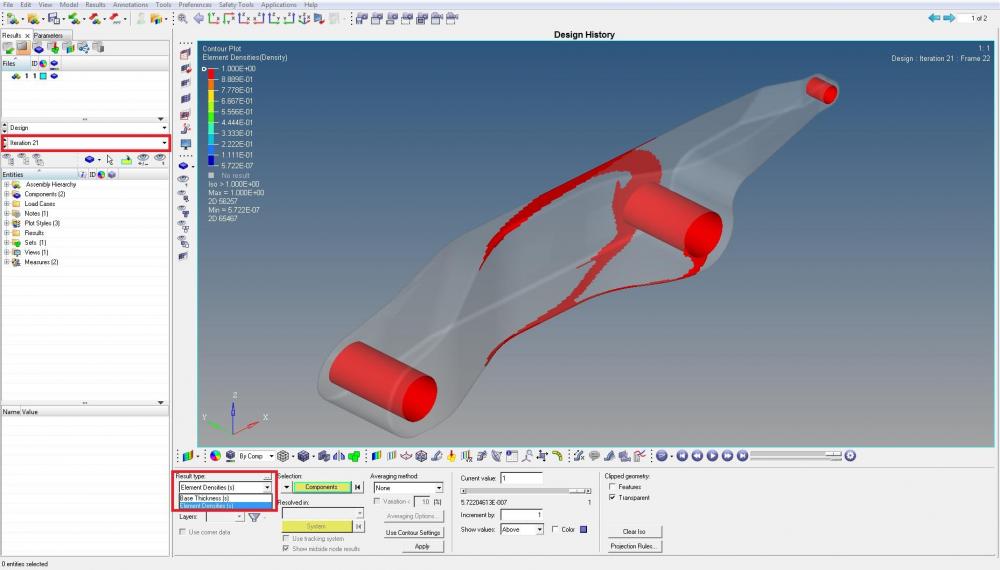

I am in need of help setting up an Optistruct run. I want to optimize wall thickness with a upper limit on stress. I have used a 2D automesh and I have a DTPL that veries wall thickness of the main body a base of 1.0mm to 10mm (defined by material property). I have the objective of the Optimization to Minimize VolFrac, and the responses set to VolFrac and StaticStress. Lastly I have set the upper bound of StaticStress to be the Failure stress with a OptimizationConstraint.

Whenever I run the Optimization the wall thickness does not very with every iteration (stays at 1.0mm). Attached is my .hm model. Is there a tutorial that shows you how to do this?

Thanks!

Find more posts tagged with

Sort by:

1 - 1 of

11

Hi,

topology optimization uses element density as a design variable, not thickness. The objective of topology optimization is to determine where to locate ribs in the designable region. Non-zero base thickness is defined to avoid holes and set constant minimum thickness. The maximum thickness, which is defined by the T field on the PSHELL card, should be the allowable depth of the rib.

For details on base thickness refer to tutorial:

OS-T: 2020 Increasing Natural Frequencies of an Automotive Splash Shield with Ribs

Stress constraint can be defined in the topology panel itself i.e. within the DTPL card. However (form Optistruct Help):

Some observations/recommendations:

<?xml version="1.0" encoding="UTF-8"?>

Unable to find an attachment - read this blog