Hi,

I am trying to do a simple optimization, refer to the following example.

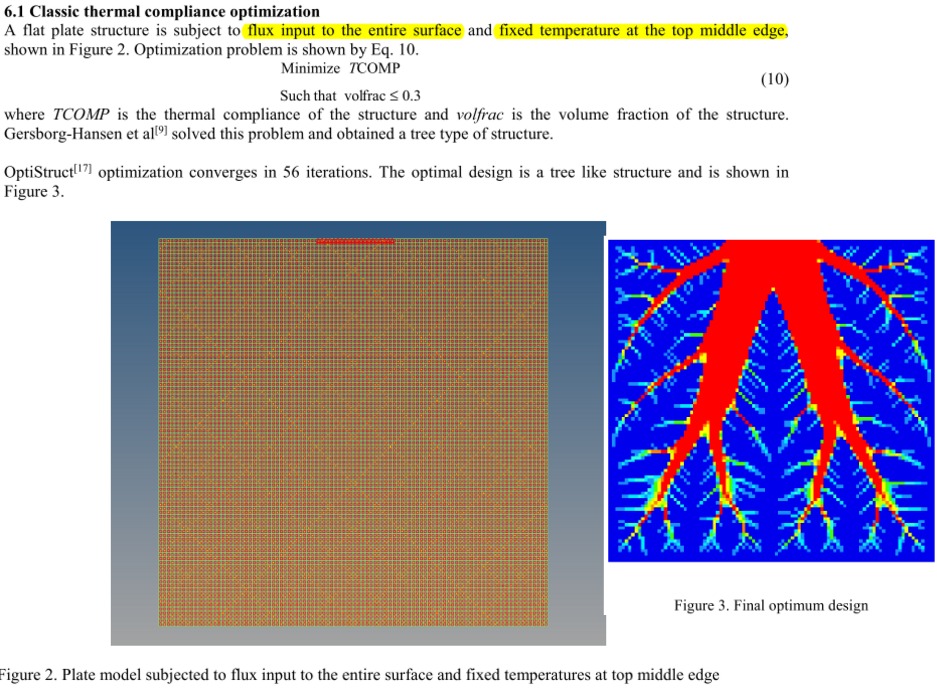

I have make a fixed temperature at the top middle edge, but have error to run.

How can I make a flux input to the entire surface? I am thinking that the flux input can't applied on Design_Space domain , right?

I also attached my FEM file, for your reference.

Unable to find an attachment - read this blog